Computer Science

IT Domain – Intelligent Detection and Real-Time Web Monitoring

The Smart Conveyor System project aims to create an intelligent waste-sorting conveyor for TEKBOT CITY. Using an ATmega328P microcontroller, color sensor, and presence detector, the system identifies and sorts four types of waste cubes (green, yellow, red, blue). It activates the conveyor motor only when needed and sends real-time data to a Flask-based web dashboard, allowing administrators to monitor the count of each waste type. The web interface features responsive design, battery status, audio feedback, and displays TEKBOT and TRC 2025 logos. The solution combines embedded C++ logic, Python Flask server, and modern web technologies for efficient waste management and real-time monitoring.

🎯 Objectives • 📝 Summary • 🔌 Hardware • 🌐 Technologies & Architecture • 🖥️ Web Interface • 💻 Source Code • 🧪 Results & Testing • 📚 Documentation

🎯 Objectives

Summary

This project aims to automate the sorting of four types of waste using an intelligent conveyor, with detection, identification, and real-time monitoring via a web interface.

The objective is to develop an intelligent conveyor system capable of identifying and sorting 4 types of waste represented by colored cubes (green, yellow, red, blue).

...

The objective is to develop an intelligent conveyor system capable of identifying and sorting 4 types of waste represented by colored cubes (green, yellow, red, blue).

The system should:

- Detect the presence of a waste item

- Identify its color with a color sensor

- Trigger the conveyor motor only when needed

- Transmit real-time data to a web dashboard showing the count of each waste type

📝 Summary

Key Takeaway

The system uses an Arduino to detect and sort waste, transmitting data to a modern web dashboard for real-time supervision.

This project implements a smart waste-sorting conveyor using a microcontroller (ATmega328P / Arduino Nano) connected to a color sensor and a presence detector.

An embedded program detects waste, identifies its color, and communicates the information to a Flask-based web interface in real time via serial communication.

Administrators can monitor sorted waste quantities per color through a modern, responsive dashboard including the TEKBOT and TRC 2025 logos.

🔌 Hardware

Summary

The hardware includes an ATmega328P microcontroller, color sensor, presence detector, DC motor, and power supply, all working together to automate waste sorting.

| Component | Description |

|---|---|

| Microcontroller | ATmega328P |

| Color Sensor | TCS34725 |

| Presence Detection | KY-008 laser module with photodiode / LDR |

| Conveyor Motor | DC motor controlled via driver (L298N) |

| Power Supply | Lithium battery block |

| Waste Items | 30 mm cubes (green, yellow, red, blue) |

📁 Repository Structure

Key Takeaway

The repository is organized by embedded code, web server, models, captures, and documentation for easy navigation.

smart_conveyor/

├── arduino/

│ ├── KeepDataColor.ino

│ └── algoDistanceColor.ino

├── web/

│ ├── app.py

│ ├── static/

│ ├── templates/

│ │ └── index.html

├── models/

│ └── conveyor.sldprt

├── capture final/

│ └── web_interface.png

└── README.md

🌐 Technologies & Architecture

Summary

The solution combines embedded C++, Python Flask, HTML/CSS/JS, and serial/HTTP communication for a robust, real-time system.

| Layer | Tools / Technologies |

|---|---|

| Embedded Logic | Arduino (C++) |

| Web Server | Flask (Python) |

| Frontend | HTML, CSS,JS |

| Communication | Serial (USB) via pySerial |

| Data Format | JSON / plain text |

| Deployment | Localhost or RPi-hosted Flask server |

🧭 System Architecture

Key Takeaway

The architecture links sensors, Arduino, WiFi module, and a Flask web server for seamless data flow and visualization.

+------------+ +-----------------+ +---------------------+ +---------------------+

| Sensor(s) | ----> | Arduino/Nano | ---> | Module wifi | --->| Flask Web Server |

| (Color + IR)| | (ATmega328P) | | (ESP-01) | | (Data Collection +|

+------------+ +-----------------+ | | | Visualization) |

+---------------------+ +---------------------+

🖥️ Web Interface

Summary

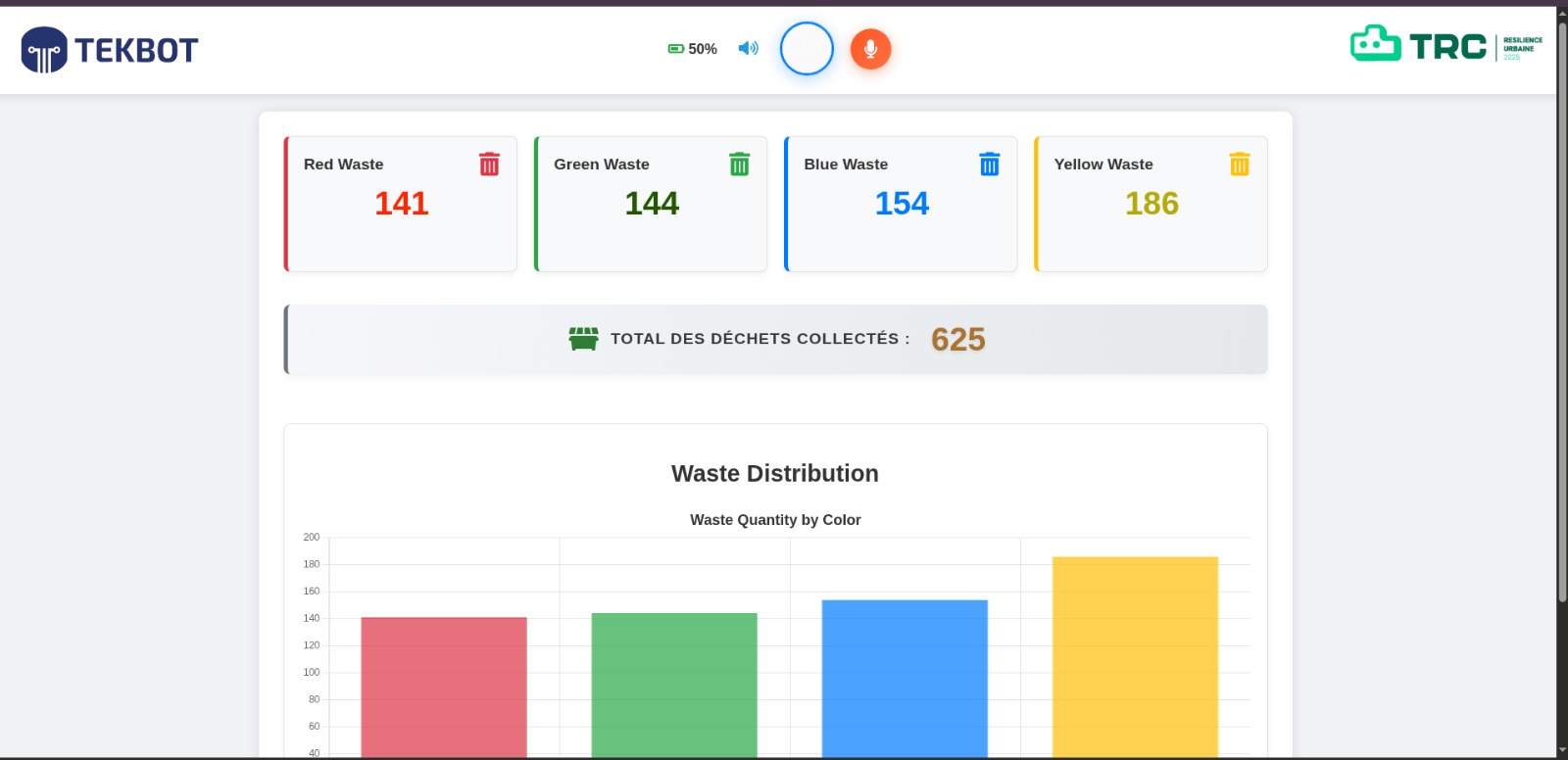

The web interface displays real-time waste counts, system status, battery level, and a dynamic chart, all in a modern, responsive dashboard.

The web interface displays:

- The total count of each waste type (green, yellow, red, blue)

- Real-time updates upon detection

- Embedded logos of TEKBOT and TRC 2025

- A clean and responsive layout

- Battery Display

- Audio

💻 Source Code

Key Takeaway

The codebase includes Arduino logic for color calibration and detection, ESP8266 code for Wi-Fi data transfer, and Flask server code for data collection and visualization.

🧠 Arduino Embedded Logic

KeepDataColor

Before calibration, the user selects which color to calibrate (red, green, blue, yellow) via the serial monitor. For each color, the sensor takes several readings, normalizes the RGB values, and calculates the average. These reference values are stored in EEPROM for later use. The process ensures accurate color recognition by adapting to the specific cubes used. The code prints each reading and the final average to help the user verify calibration quality.

#include <Wire.h>

#include <Adafruit_TCS34725.h>

#include <EEPROM.h>

// Initialisation du capteur TCS34725

Adafruit_TCS34725 tcs = Adafruit_TCS34725(TCS34725_INTEGRATIONTIME_50MS, TCS34725_GAIN_4X);

// Structure pour stocker les valeurs de référence

struct ColorRef {

String name;

float r_ref;

float g_ref;

float b_ref;

};

// Tableau des couleurs à calibrer

ColorRef colors[] = {

{"Rouge", 0.0, 0.0, 0.0},

{"Vert", 0.0, 0.0, 0.0},

{"Bleu", 0.0, 0.0, 0.0},

{"Jaune", 0.0, 0.0, 0.0}

};

const int numColors = 4;

const int numReadings = 10; // Nombre de lectures par couleur

const int eepromBaseAddr = 0; // Adresse de départ dans l'EEPROM

void setup() {

Serial.begin(9600);

while (!Serial); // Attendre que le moniteur série soit prêt

if (tcs.begin()) {

Serial.println("Capteur TCS34725 détecté !");

} else {

Serial.println("Erreur : capteur TCS34725 non détecté. Vérifiez les connexions !");

while (1); // Boucle infinlisten

// Instructions pour l'utilisateur

Serial.println("Programme de calibrage des couleurs.");

Serial.println("Entrez le numéro de la couleur à calibrer :");

Serial.println("1: Rouge, 2: Vert, 3: Bleu, 4: Jaune");

}

}

void loop() {

if (Serial.available() > 0) {

int choice = Serial.parseInt();

if (choice >= 1 && choice <= numColors) {

String colorName = colors[choice - 1].name;

Serial.print("Calibration pour "); Serial.print(colorName); Serial.println(". Placez l'échantillon de couleur et attendez...");

float r_sum = 0.0, g_sum = 0.0, b_sum = 0.0;

int validReadings = 0;

// Collecter numReadings lectures

for (int i = 0; i < numReadings; i++) {

uint16_t r, g, b, c;

tcs.getRawData(&r, &g, &b, &c);

// Normaliser les valeurs

float sum = r + g + b;

if (sum == 0) sum = 1; // Éviter la division par zéro

float r_norm = r / sum;

float g_norm = g / sum;

float b_norm = b / sum;

// Vérifier si la lecture est valide (intensité suffisante)

// if (c > 500) { // Seuil pour éviter le bruit

r_sum += r_norm;

g_sum += g_norm;

b_sum += b_norm;

validReadings++;

Serial.print("Lecture "); Serial.print(i + 1);

Serial.print(": R_norm="); Serial.print(r_norm, 3);

Serial.print(" G_norm="); Serial.print(g_norm, 3);

Serial.print(" B_norm="); Serial.print(b_norm, 3);

Serial.println();

// } else {

// Serial.println("Lecture ignorée : intensité lumineuse trop faible.");

}

delay(500); // Attendre 500 ms entre les lectures

//}

// Calculer et afficher la moyenne

if (validReadings > 0) {

colors[choice - 1].r_ref = r_sum / validReadings;

colors[choice - 1].g_ref = g_sum / validReadings;

colors[choice - 1].b_ref = b_sum / validReadings;

Serial.print("Moyenne pour "); Serial.print(colorName); Serial.print(": ");

Serial.print("R_ref="); Serial.print(colors[choice - 1].r_ref, 3);

Serial.print(" G_ref="); Serial.print(colors[choice - 1].g_ref, 3);

Serial.print(" B_ref="); Serial.print(colors[choice - 1].b_ref, 3);

Serial.print(" (basé sur "); Serial.print(validReadings); Serial.println(" lectures valides)");

// Sauvegarder dans l'EEPROM

int addr = eepromBaseAddr + (choice - 1) * sizeof(ColorRef);

EEPROM.put(addr, colors[choice - 1]);

} else {

Serial.println("Erreur : aucune lecture valide pour cette couleur.");

}

// Demander la couleur suivante

Serial.println("\nEntrez le numéro de la couleur suivante (1-4), ou 0 pour terminer :");

} else if (choice == 0) {

// Afficher toutes les valeurs de référence

Serial.println("\nRésultats finaux des valeurs de référence :");

for (int i = 0; i < numColors; i++) {

Serial.print(colors[i].name); Serial.print(": ");

Serial.print("R_ref="); Serial.print(colors[i].r_ref, 3);

Serial.print(" G_ref="); Serial.print(colors[i].g_ref, 3);

Serial.print(" B_ref="); Serial.print(colors[i].b_ref, 3);

Serial.println();

}

Serial.println("Calibration terminée. Copiez ces valeurs dans un fichier.");

while (1); // Arrêter après la calibration

} else {

Serial.println("Choix invalide. Entrez 1-4 pour une couleur, ou 0 pour terminer.");

}

// Vider le tampon série

while (Serial.available() > 0) Serial.read();

}

}

algoDistanceColor

This code uses the previously calibrated reference values to identify the color of detected objects. For each sensor reading, it normalizes the RGB values and compares them to each reference color using Euclidean distance. The closest match is selected, provided the light intensity is sufficient and the distance is below a threshold. The detected color is printed to the serial monitor, allowing real-time tracking of waste sorting.

#include <Wire.h>

#include <Adafruit_TCS34725.h>

#include <EEPROM.h>

#include <math.h>

// Initialisation du capteur TCS34725

Adafruit_TCS34725 tcs = Adafruit_TCS34725(TCS34725_INTEGRATIONTIME_50MS, TCS34725_GAIN_4X);

// Structure pour stocker les valeurs de référence

struct ColorRef {

String name;

float r_ref;

float g_ref;

float b_ref;

};

// Tableau des couleurs de référence (valeurs par défaut si EEPROM vide)

ColorRef colors[] = {

{"Rouge", 0.8, 0.1, 0.1},

{"Vert", 0.1, 0.8, 0.1},

{"Bleu", 0.1, 0.1, 0.8},

{"Jaune", 0.5, 0.45, 0.05}

};

const int numColors = 4;

const int eepromBaseAddr = 0; // Adresse de départ dans l'EEPROM

void setup() {

Serial.begin(9600);

while (!Serial); // Attendre que le moniteur série soit prêt

if (tcs.begin()) {

Serial.println("Capteur TCS34725 détecté !");

} else {

Serial.println("Erreur : capteur TCS34725 non détecté. Vérifiez les connexions !");

while (1); // Boucle infinie en cas d'erreur

}

// Charger les valeurs de référence depuis l'EEPROM

for (int i = 0; i < numColors; i++) {

ColorRef temp;

EEPROM.get(eepromBaseAddr + i * sizeof(ColorRef), temp);

// Vérifier si les valeurs sont valides (non nulles et cohérentes)

if (temp.r_ref + temp.g_ref + temp.b_ref > 0.1) { // Somme non nulle

colors[i] = temp;

}

}

// Afficher les valeurs de référence utilisées

Serial.println("Valeurs de référence utilisées :");

for (int i = 0; i < numColors; i++) {

Serial.print(colors[i].name); Serial.print(": ");

Serial.print("R_ref="); Serial.print(colors[i].r_ref, 3);

Serial.print(" G_ref="); Serial.print(colors[i].g_ref, 3);

Serial.print(" B_ref="); Serial.print(colors[i].b_ref, 3);

Serial.println();

}

}

void loop() {

uint16_t r, g, b, c;

float r_norm, g_norm, b_norm;

// Lire les données brutes du capteur

tcs.getRawData(&r, &g, &b, &c);

// Normaliser les valeurs RVB

float sum = r + g + b;

if (sum == 0) sum = 1; // Éviter la division par zéro

r_norm = r / sum;

g_norm = g / sum;

b_norm = b / sum;

// Afficher les valeurs normalisées pour débogage

Serial.print("R_norm: "); Serial.print(r_norm, 3);

Serial.print(" G_norm: "); Serial.print(g_norm, 3);

Serial.print(" B_norm: "); Serial.print(b_norm, 3);

Serial.print(" Clear: "); Serial.println(c);

// Trouver la couleur la plus proche

String detectedColor = "Inconnue";

float minDistance = 1000.0; // Valeur initiale élevée

for (int i = 0; i < numColors; i++) {

// Calculer la distance euclidienne

float distance = sqrt(

pow(r_norm - colors[i].r_ref, 2) +

pow(g_norm - colors[i].g_ref, 2) +

pow(b_norm - colors[i].b_ref, 2)

);

// Afficher la distance pour débogage

Serial.print("Distance à "); Serial.print(colors[i].name);

Serial.print(": "); Serial.println(distance, 3);

// Mettre à jour la couleur détectée si la distance est plus faible

if (distance < minDistance) {

minDistance = distance;

detectedColor = colors[i].name;

}

}

// Vérifier le seuil de distance et l'intensité lumineuse

if (minDistance > 0.3 || c < 1000) {

detectedColor = "Inconnue (distance trop grande ou lumière faible)";

}

// Afficher la couleur détectée

Serial.print("Couleur détectée : "); Serial.println(detectedColor);

Serial.println("---");

delay(1000); // Attendre 1 seconde avant la prochaine lecture

}

🌐 Flask Web Server

Summary

The ESP8266 connects to Wi-Fi and sends HTTP requests to the Flask server, enabling real-time data transfer from the microcontroller to the dashboard.

#include <ESP8266WiFi.h>

#include <ESP8266HTTPClient.h>

#include <WiFiClient.h>

#include <ArduinoJson.h> // Nécessaire pour envoyer du JSON

const char* ssid = "MOOVAFRICA_320139";

const char* password = "b2652aa6";

// --- Configuration du serveur Flask ---

const char* flaskServerHost = "192.168.1.100";

const int flaskServerPort = 5000;

const char* apiEndpoint = "/api/set?color=blue"; // Le chemin de l'API sur votre serveur Flask

unsigned long previousMillis = 0;

const long interval = 2000; // Intervalle d'envoi des données (en ms)

void setup() {

Serial.begin(115200);

delay(10);

Serial.println();

Serial.print("Connecting to ");

Serial.println(ssid);

WiFi.begin(ssid, password);

// Attendre la connexion Wi-Fi

int retries = 0;

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

retries++;

if (retries > 20) {

Serial.println("\nFailed to connect to WiFi. Please check SSID/Password and signal.");

}

}

Serial.println("");

Serial.println("WiFi connected");

Serial.println("IP address: ");

Serial.println(WiFi.localIP());

}

void loop() {

unsigned long currentMillis = millis();

if (currentMillis - previousMillis >= interval) {

previousMillis = currentMillis;

WiFiClient client;

HTTPClient http;

String serverPath = "http://" + String(flaskServerHost) + ":" + String(flaskServerPort) + String(apiEndpoint);

Serial.print("[HTTP] begin...\n");

if (http.begin(client, serverPath)) {

Serial.print("[HTTP] GET...\n");

int httpCode = http.GET();

if (httpCode > 0) {

Serial.printf("[HTTP] GET... code: %d\n", httpCode);

if (httpCode == HTTP_CODE_OK || httpCode == HTTP_CODE_MOVED_PERMANENTLY) {

String payload = http.getString();

Serial.println(payload);

}

} else {

Serial.printf("[HTTP] POST... failed, error: %s\n", http.errorToString(httpCode).c_str());

}

http.end();

} else {

Serial.printf("[HTTP] Unable to connect\n");

}

}

yield();

}

🖼️ Web Dashboard (HTML Template)

Key Takeaway

The dashboard is responsive, user-friendly, and visually summarizes all waste data in real time.

<!-- templates/index.html -->

<!DOCTYPE html>

<html lang="en">

<head>

<meta charset="UTF-8" />

<meta name="viewport" content="width=device-width, initial-scale=1.0"/>

<title>TekBot | DashBoard</title>

<link rel="stylesheet" href="../static/style.css"/>

<link rel="stylesheet" href="https://cdnjs.cloudflare.com/ajax/libs/font-awesome/6.0.0-beta3/css/all.min.css"/>

<script src="https://cdn.jsdelivr.net/npm/chart.js"></script>

</head>

<body>

<nav class="navbar">

<div class="navbar-left">

<img src="../static/logo.png" alt="Logo Tekbot" class="logo" />

</div>

<div class="navbar-utils">

<div class="battery-info">

<i class="fas fa-battery-three-quarters battery-icon"></i>

<span class="battery-level">--%</span>

</div>

<button class="volume-btn" onclick="lireRapport()">

<i class="fas fa-volume-up volume-icon"></i>

</button>

</div>

<div class="navbar-right">

<img src="../static/trc.png" alt="Logo TRC" class="logo" />

</div>

</nav>

<div class="dashboard-container">

<div class="card-section">

<div class="card red">

<div class="card-header">

<h3>Red Waste</h3>

<i class="fa-solid fa-trash-can waste-icon"></i>

</div>

<p class="value"><span id="rouge-count">{{ red }}</span></p>

</div>

<div class="card green">

<div class="card-header">

<h3>Green Waste</h3>

<i class="fa-solid fa-trash-can waste-icon"></i>

</div>

<p class="value1"><span id="vert-count">{{ green }}</span></p>

</div>

<div class="card blue">

<div class="card-header">

<h3>Blue Waste</h3>

<i class="fa-solid fa-trash-can waste-icon"></i>

</div>

<p class="value2"><span id="bleu-count">{{ blue }}</span></p>

</div>

<div class="card yellow">

<div class="card-header">

<h3>Yellow Waste</h3>

<i class="fa-solid fa-trash-can waste-icon"></i>

</div>

<p class="value3"><span id="jaune-count">{{ yellow }}</span></p>

</div>

<!-- Carte du Total (nouvelle structure) -->

<div class="total-card">

<div class="total-content">

<i class="fas fa-dumpster total-icon"></i>

<div class="total-text">Total des déchets collectés :</div>

<div class="total-value" id="total-count">{{ red + green + blue + yellow }}</div>

</div>

</div>

<!-- Graphique ( -->

<div class="chart-fullwidth">

<h2 class="chart-title">Waste Distribution</h2>

<canvas id="wasteHistogram"></canvas>

</div>

<script src="../static/script.js"></script>

</body>

</html>

🎥 Demo Videos

Key Takeaway

The demo shows real-time data flow from the ROS2 publisher to the web dashboard, with instant updates and dynamic visualization.

Demo Description:

A ROS node publisher generates random waste colors and sends them to the system. The web interface receives these updates, automatically refreshes the waste counts, and displays the changes in real time. This demonstrates the live data flow and dynamic dashboard updates for the smart conveyor system.

Simulation Interface avec ROS

🧪 Results & Testing

Summary

The system was tested for detection, sorting, real-time updates, and interface clarity, all with successful outcomes.

| Test Scenario | Expected Result | Outcome |

|---|---|---|

| Waste detected and identified correctly | Color is logged and counted | ✅ Success |

| Motor activates only when needed | Conveyor runs during detection | ✅ Success |

| Real-time interface update | Dashboard shows new counts instantly | ✅ Success |

| Interface displays all 4 types clearly | All colors tracked | ✅ Success |

| TRC & TEKBOT logos visible | Logos displayed | ✅ Success |

📚 References

Key Takeaway

Documentation and resources for Arduino, Flask, Chart.js, and hardware components.

Arduino Documentation

- Arduino Official Documentation

- Adafruit TCS34725 Color Sensor Guide

- EEPROM Library Reference

- Serial Communication Reference

Flask & Web Dashboard

Hardware & Design

👥 Team

Key Takeaway

Project developed by a multidisciplinary team for the TEKBOT Robotics Challenge 2025.

- Marzoukath AGBODJA

- Ifè Leonce COMLAN

- Larissa CHATIGRE

Final Project – TEKBOT Robotics Challenge 2025

Domain: IT

Stack: Arduino (C++) + Flask + HTML/CSS

© 2025 TEKBOT Robotics Challenge