1rst Test

Objectives

- Produce a batch of parts within a limited time frame while adhering to imposed constraints (materials, dimensions, etc.).

- Comply with a mass tolerance of ±5% for each manufactured part.

- Design sketches incorporating basic geometric shapes:

- Rectangles

- Circles

- Polygons

- Use extrusion and revolution features to model 3D parts based on the sketches.

- Evaluate the mass of each part.

Summary

Modeling files

Access the modeling files by clicking here.

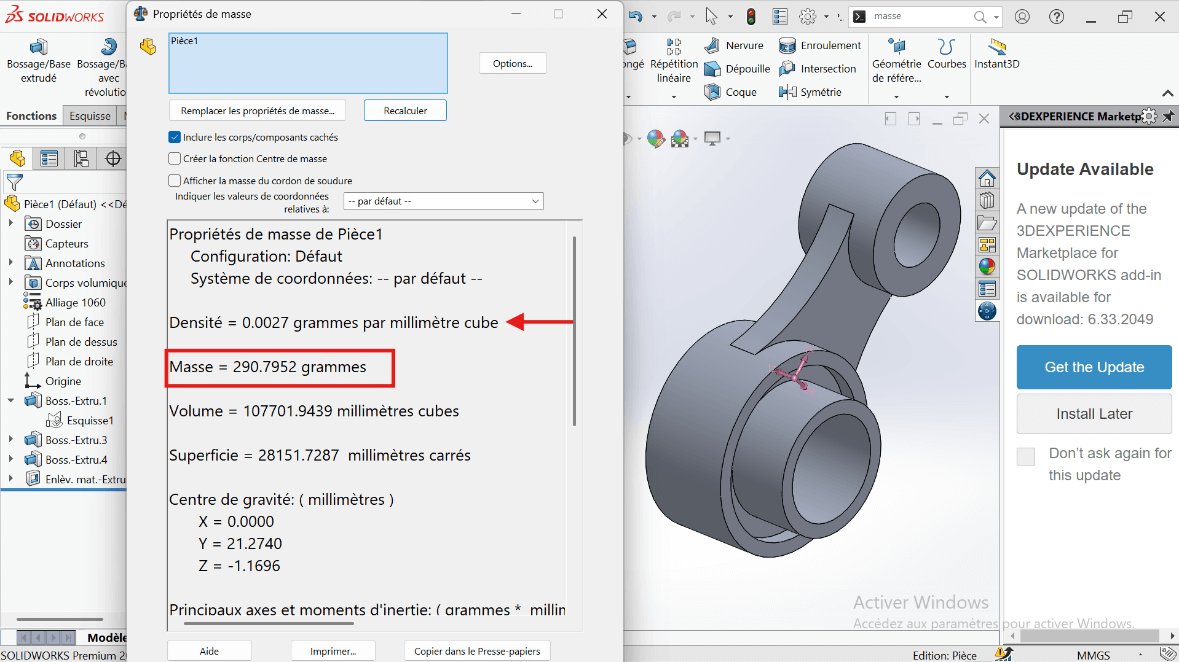

Mass Summary of Part

| Part Number | Mass (g) |

|---|---|

| Part 1 | 2850.16 |

| Part 2 | 290.79 |

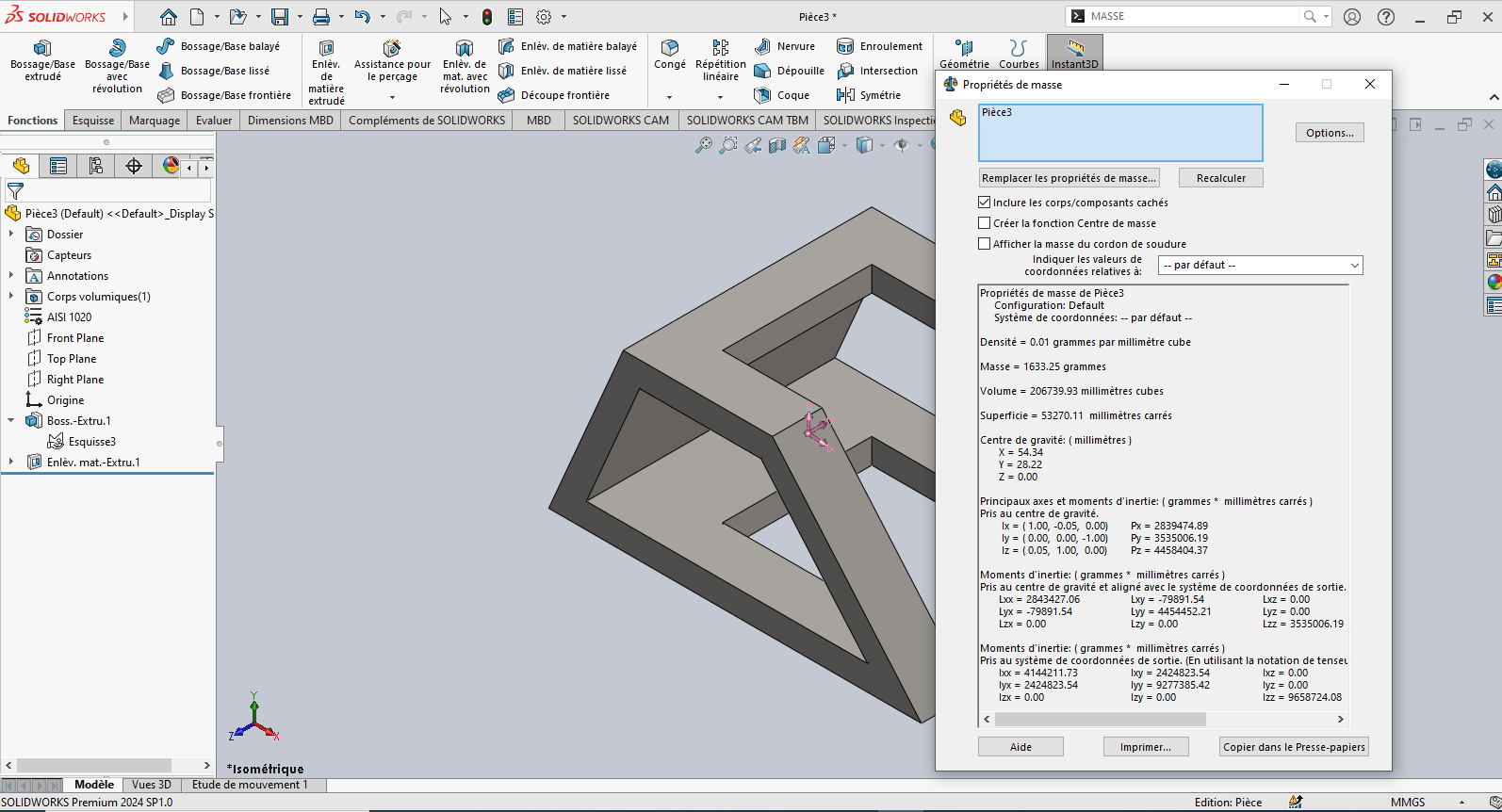

| Part 3 | 1633.25 |

| Part 4 | 112.37 |

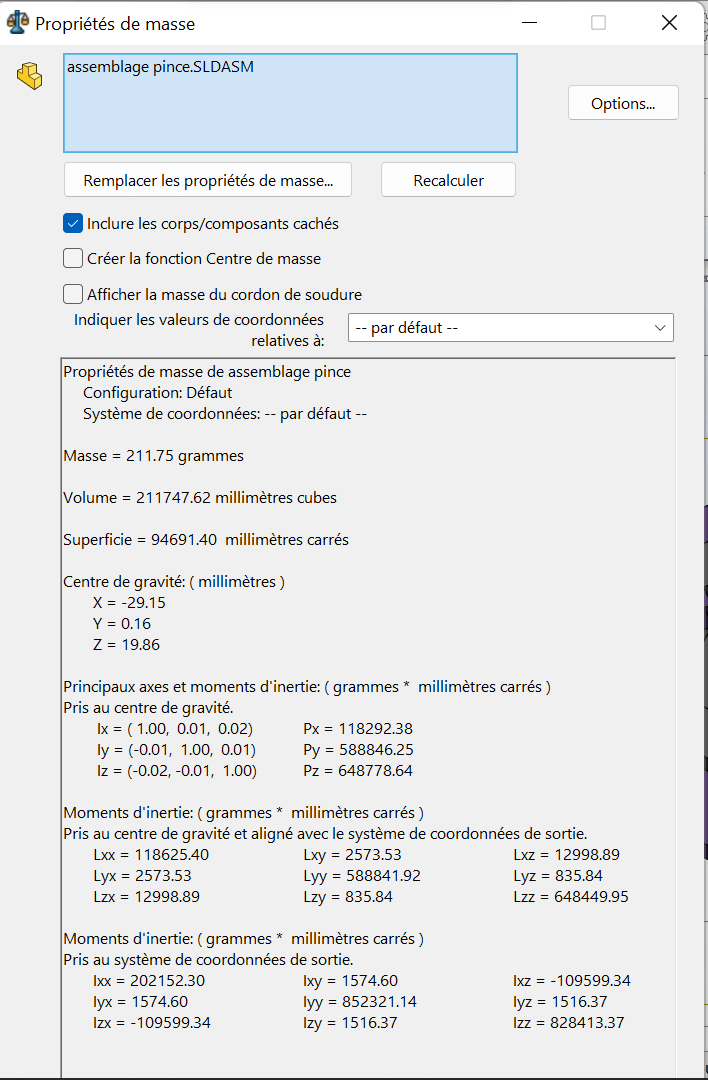

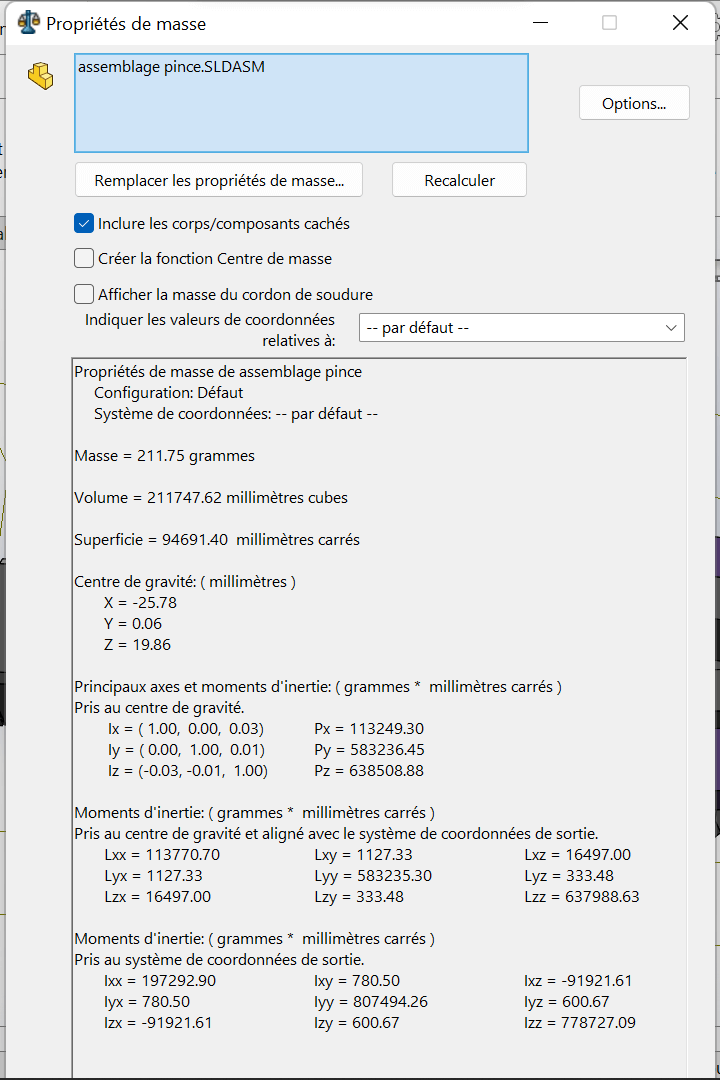

Center of Gravity Analysis – Gripper

| Configuration | X (mm) | Y (mm) | Z (mm) |

|---|---|---|---|

| Fully Open | -29.15 | 0.16 | 19.86 |

| Fully Closed | -25.78 | 0.06 | 19.86 |

Materials

- Computer

- Internet connection

Execution

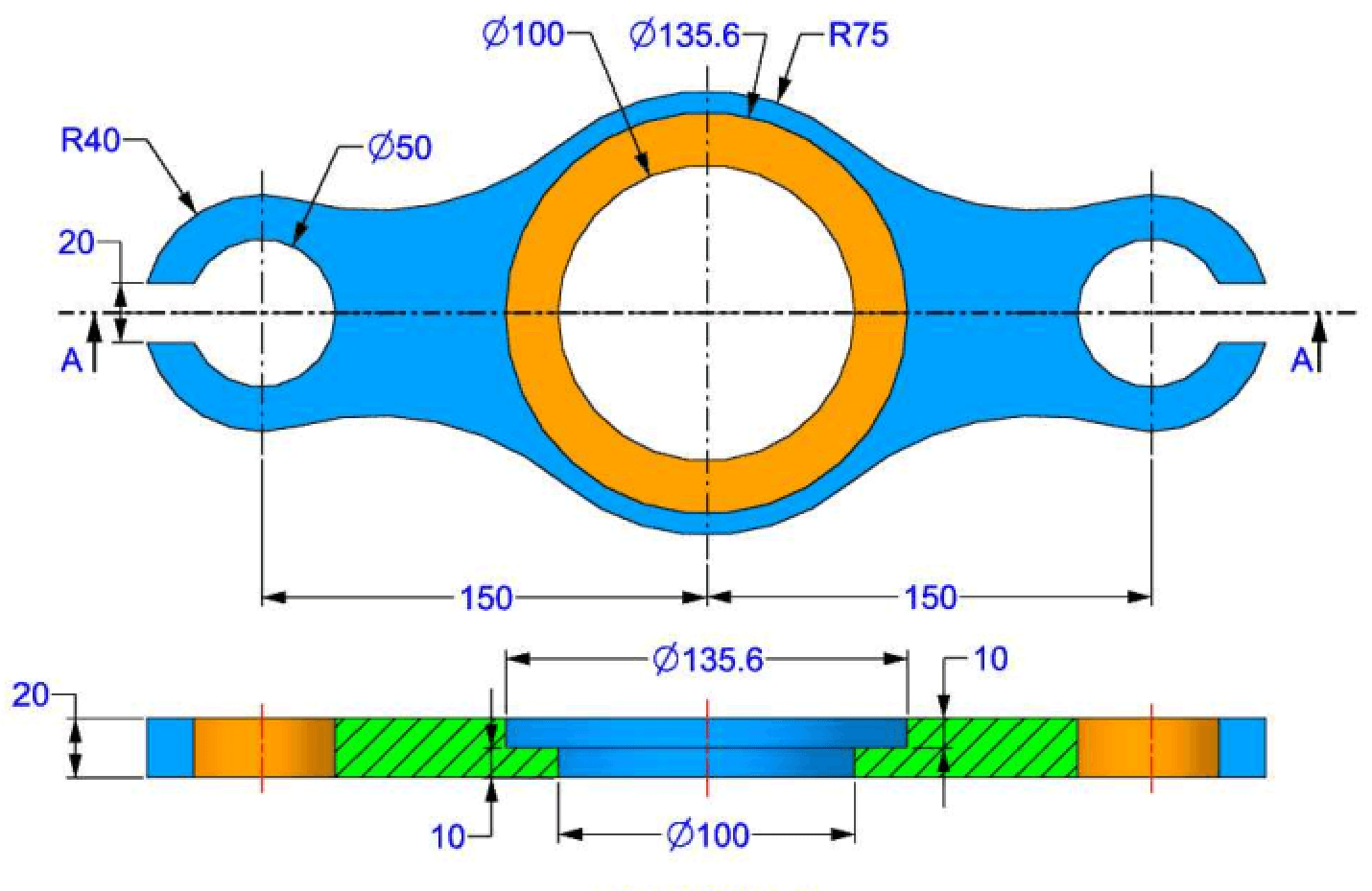

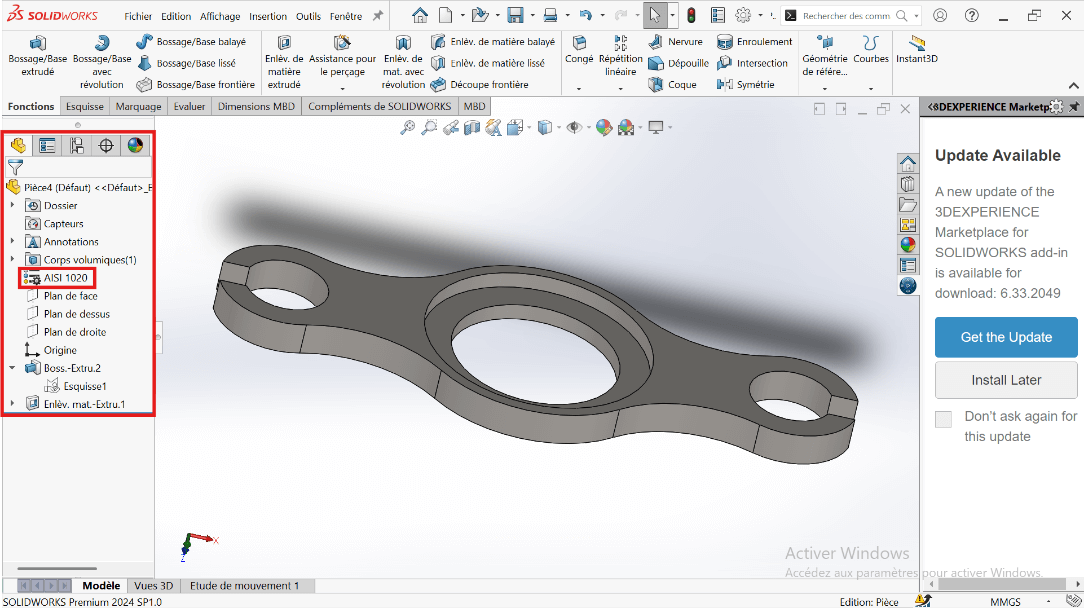

Modeling of the First Part

Unit Systems and Material Properties

- Unit System: MMGS (Millimeter, Gram, Second)

- Decimals: 2

- Hole Specification: All holes are through unless otherwise specified

- Material: AISI 1020 Steel

- Density: 0.0079 g/mm³

Process of Obtaining the Part

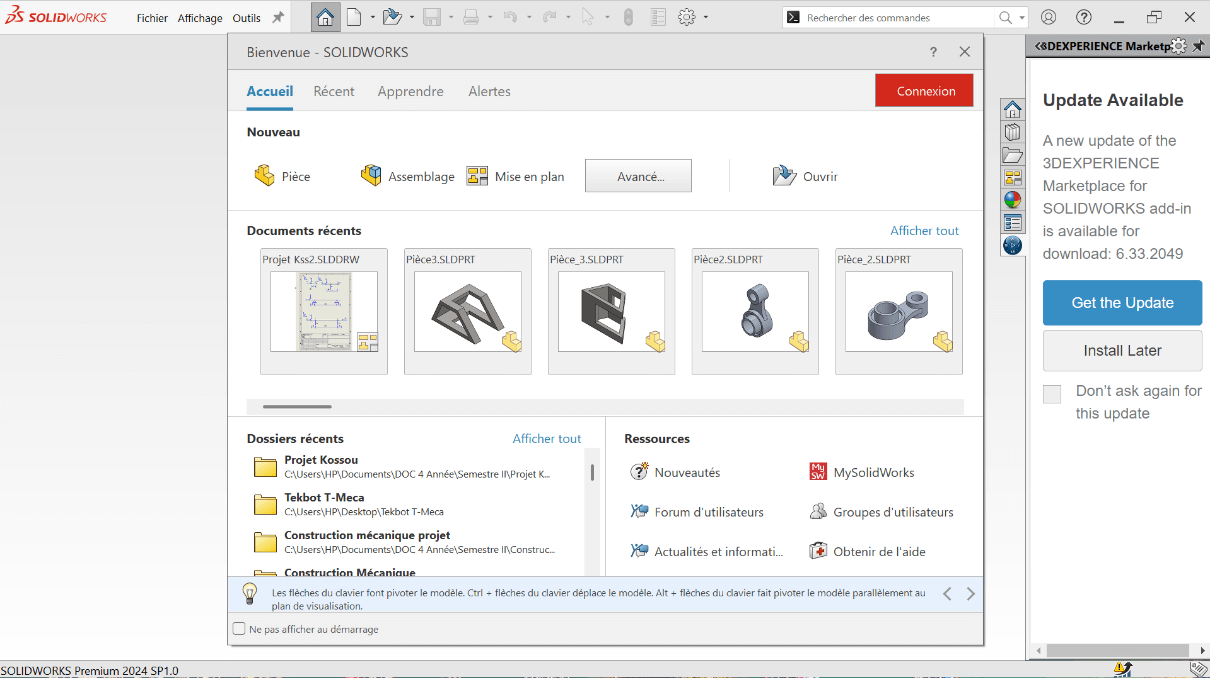

--> 1. Workspace Setup

- Launch SolidWorks and select New Part.

- Click on Piece to start modeling a new piece.

- In the design tree, right-click the Front Plane and choose Edit Sketch.

- Set the unit system to MMGS (Millimeter, Gram, Second).

- Ensure decimals are set to 2.

- Assume all holes are through unless stated otherwise.

- Assign material as AISI 1020 Steel with a density of 0.0079 g/mm³.

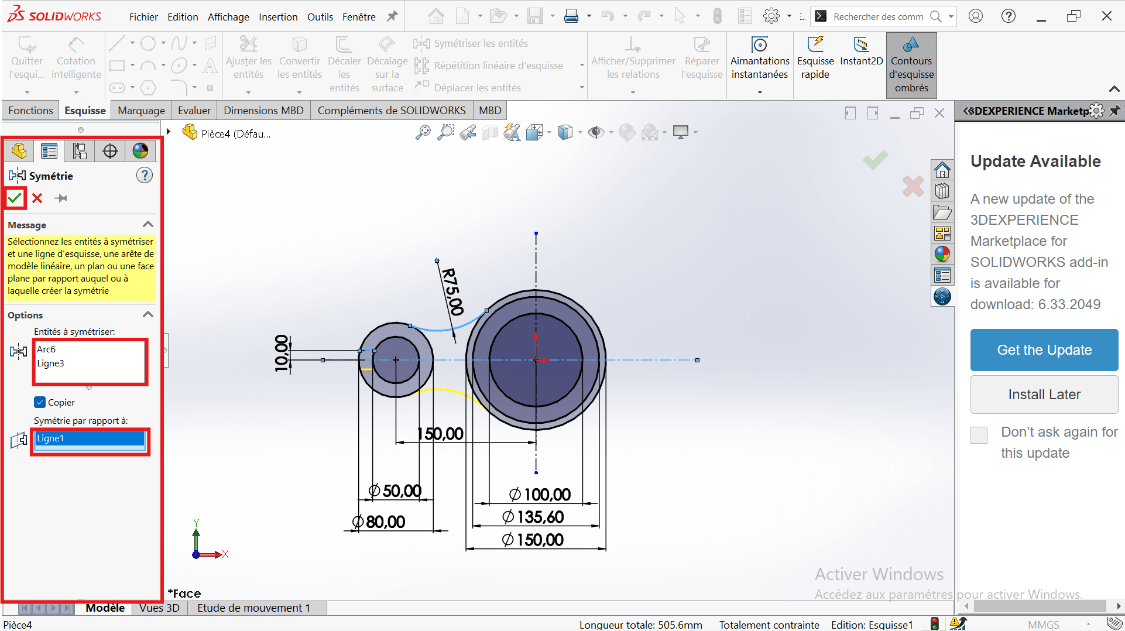

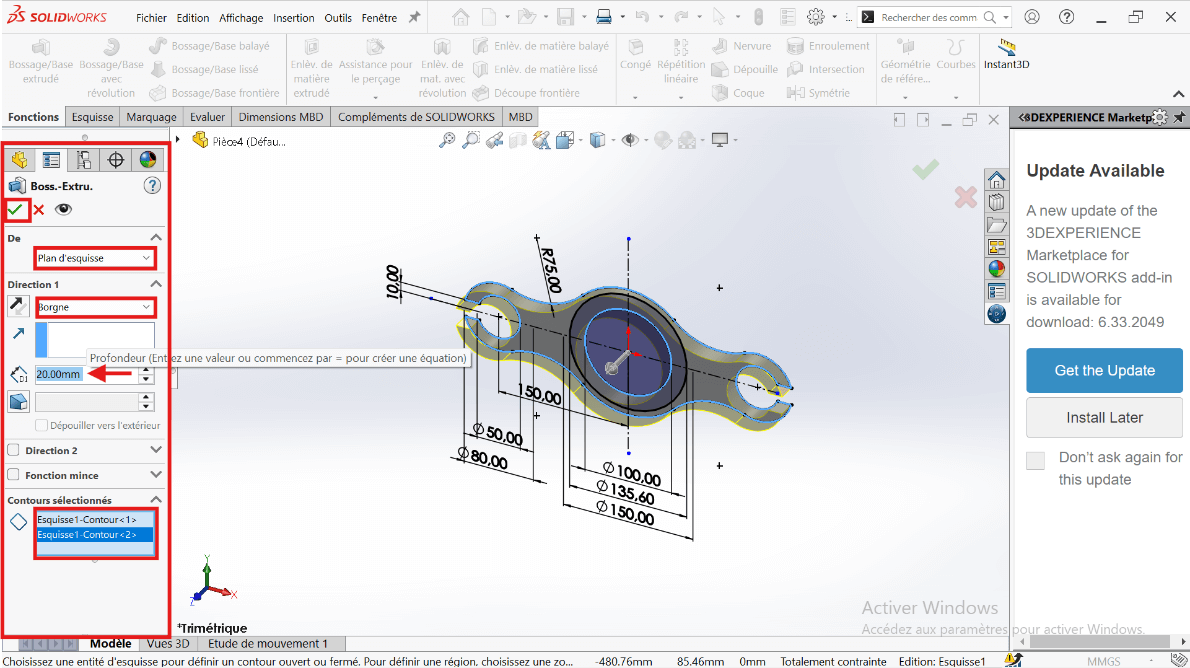

--> 2. Sketching the Base Profile

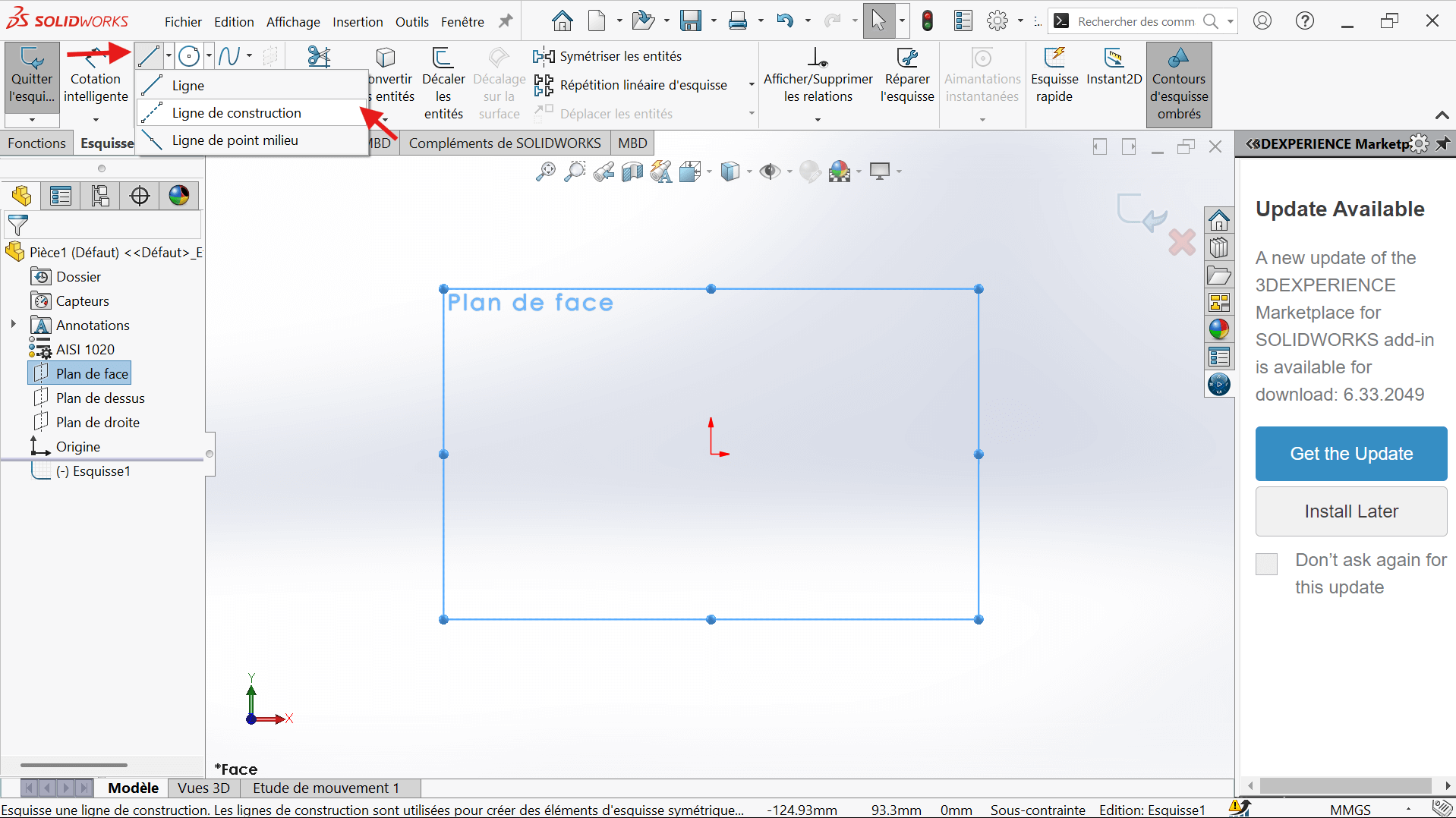

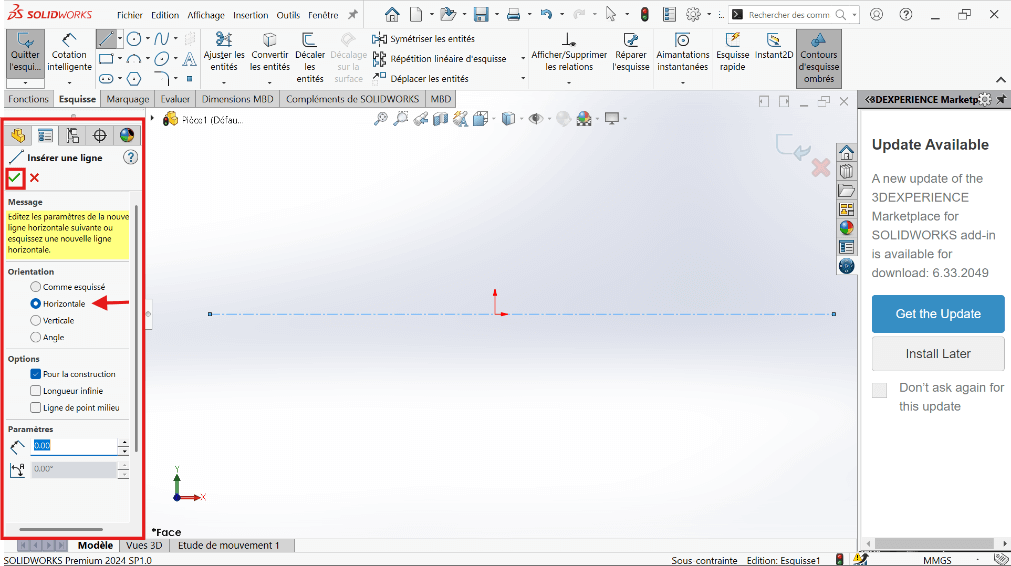

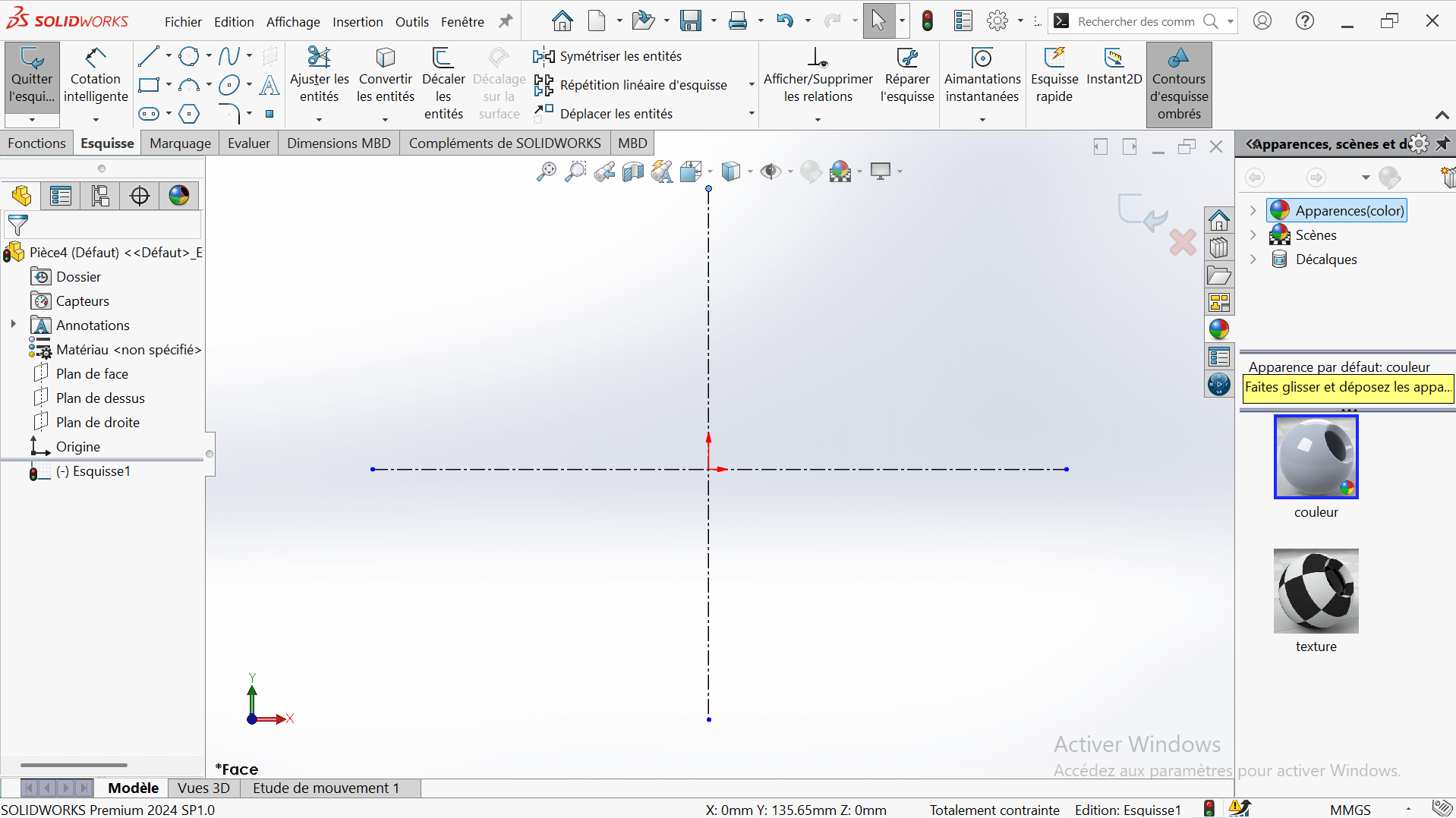

---> a. Create Centerlines

- Click on the Line function.

- Select the Horizontal Constraint and For Construction in the properties.

- Position the start and end points, ensuring alignment with the reference frame.

- Click Validate to confirm.

- Click again on the Vertical Constraint to draw the vertical axis, ensuring alignment with the reference frame.

- Click Validate to confirm.

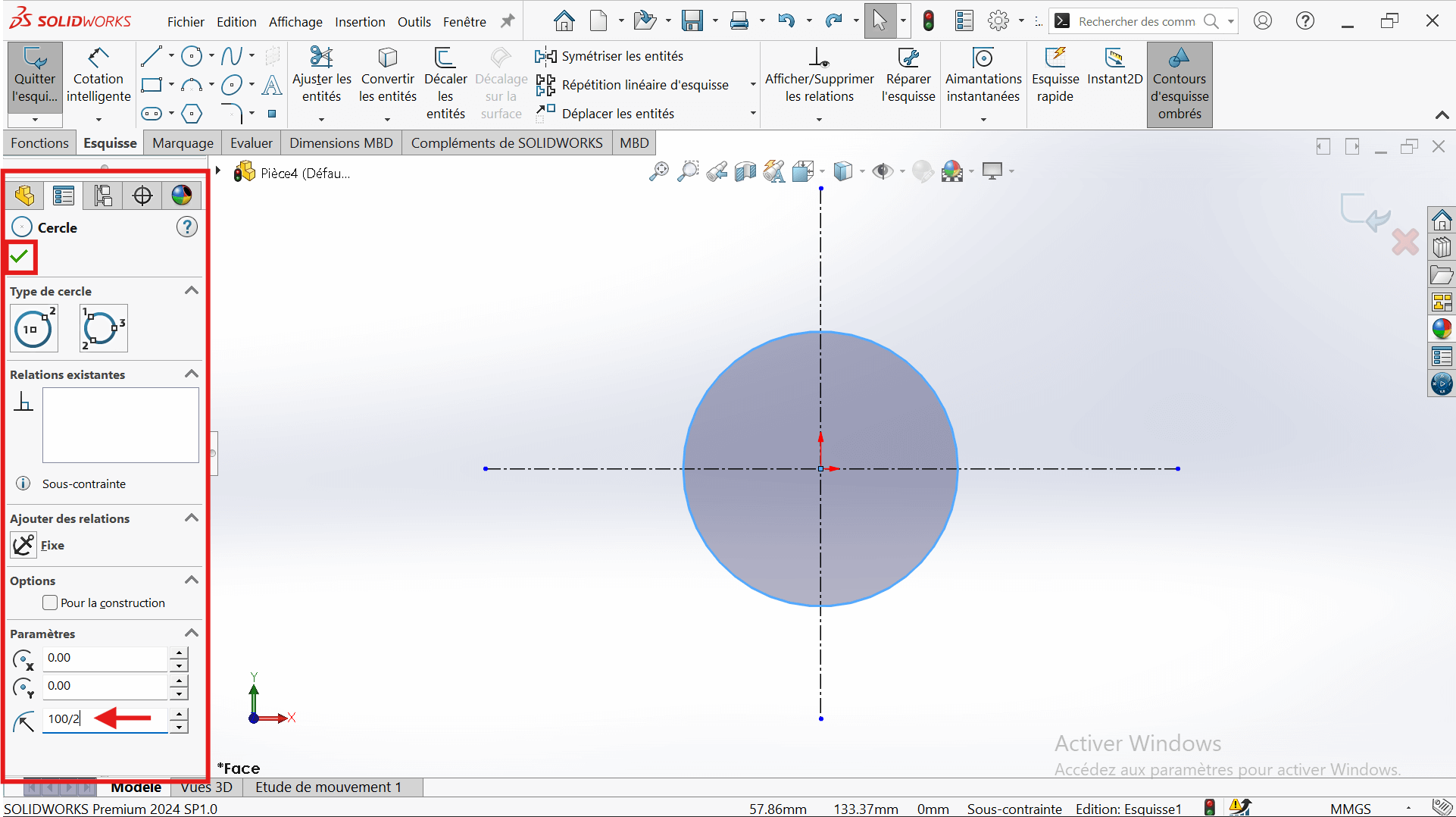

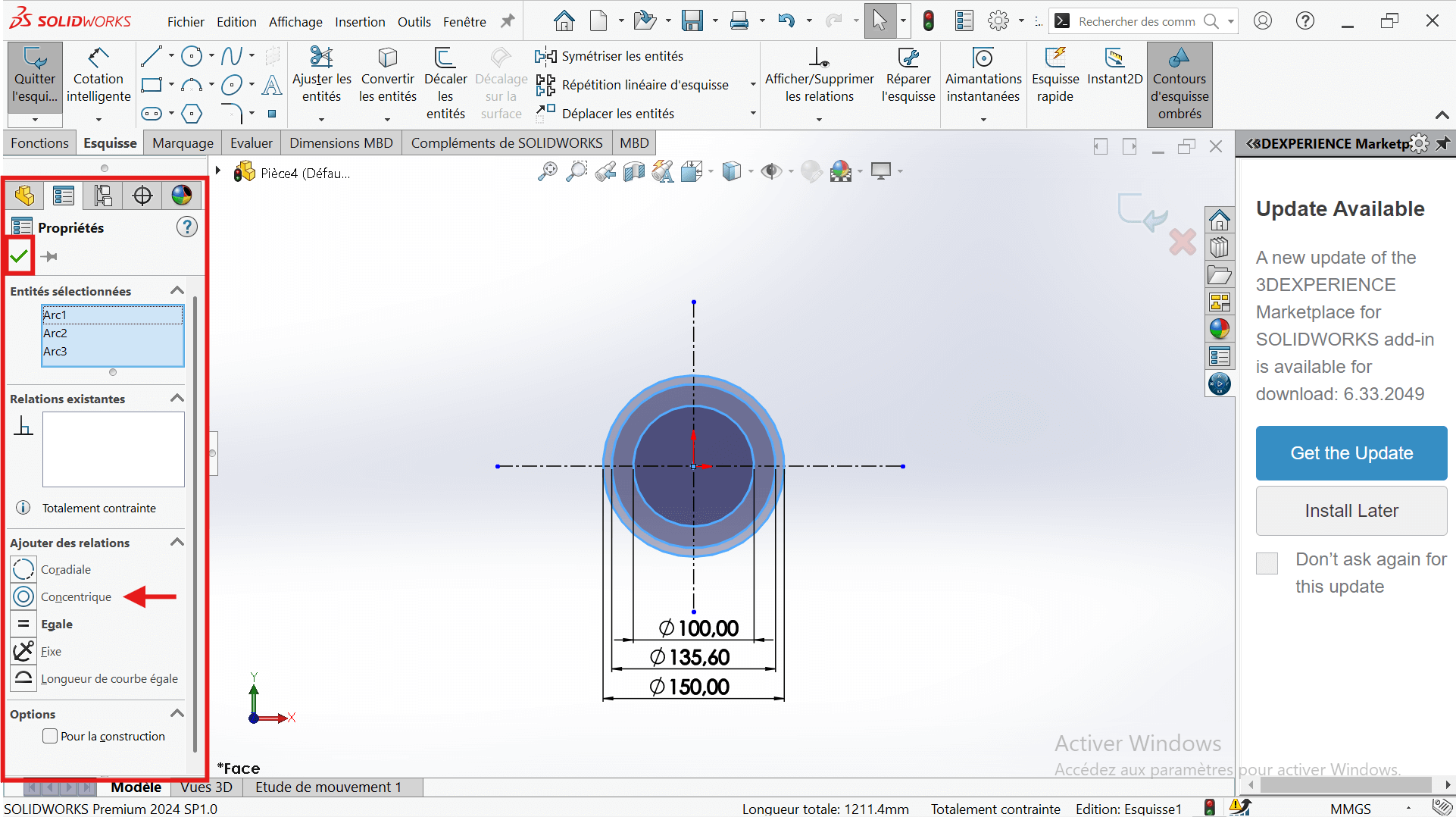

---> b. Draw Concentric Circles

- In the top ribbon, click on "Circle".

- Click on the intersection point of the two axes (center of the circle).

- Stretch the circle to any size for now.

- Enter the circle radius in the properties panel on the left.

- Select the "Smart Dimension" tool.

- Click on the edge of the circle → a diameter dimension will appear.

- Enter the value 100 mm (since the radius is 50 mm, the diameter is 100 mm).

- Click Validate to confirm.

- Draw two other circles centered on the origin:

- Diameter 135.6 mm

- Diameter 150 mm

- Apply concentricity constraints to ensure a common center.

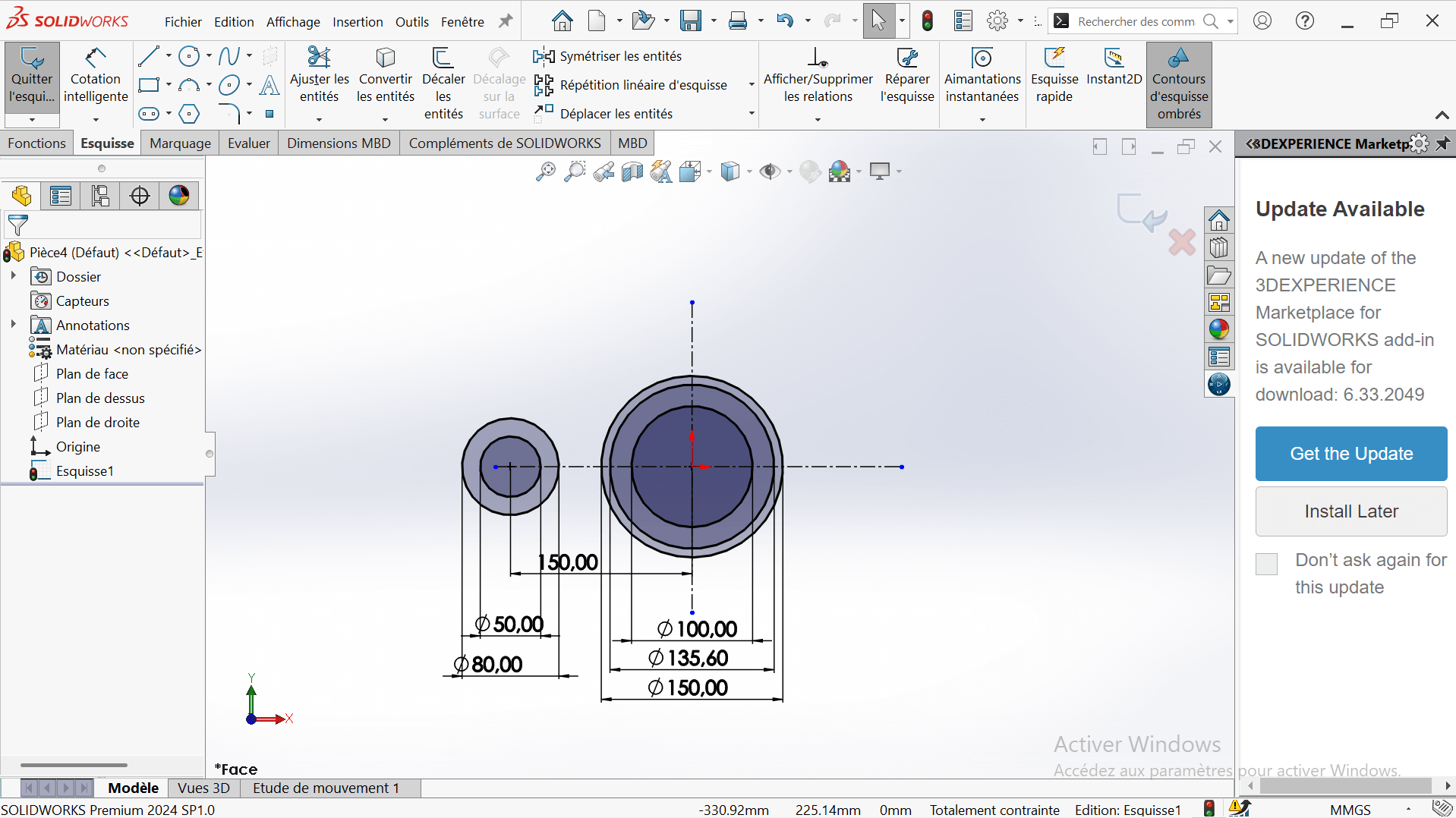

---> c. Add Offset Circle

- Create a new circle on the horizontal axis, offset from the origin.

- Set its diameter to 80 mm (radius = 40 mm).

- Use Smart Dimension to set the center-to-center distance from the 150 mm circle to 150 mm.

---> d. Add Additional Circle

- Draw another circle with a diameter of 50 mm, concentric with the 80 mm circle.

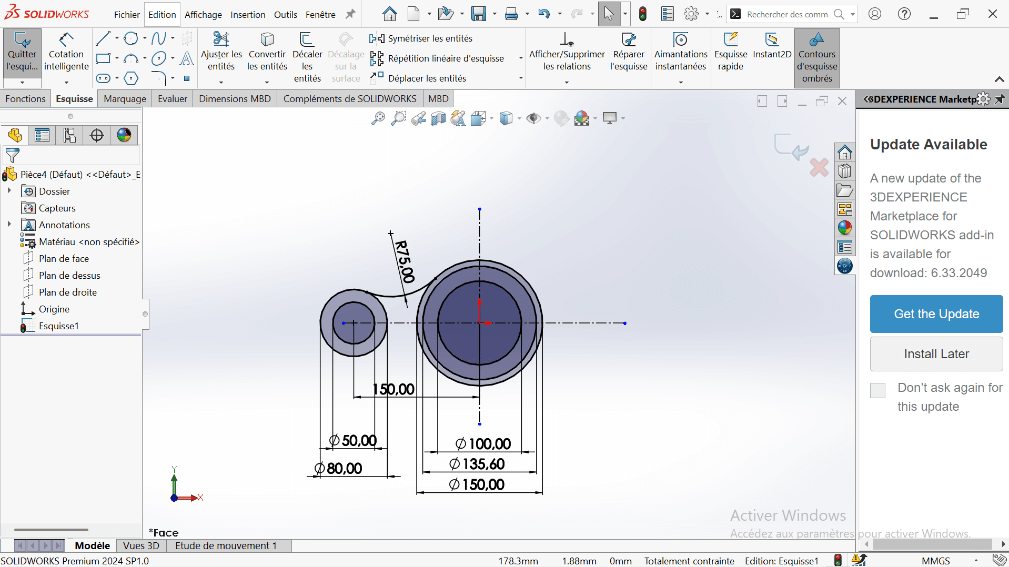

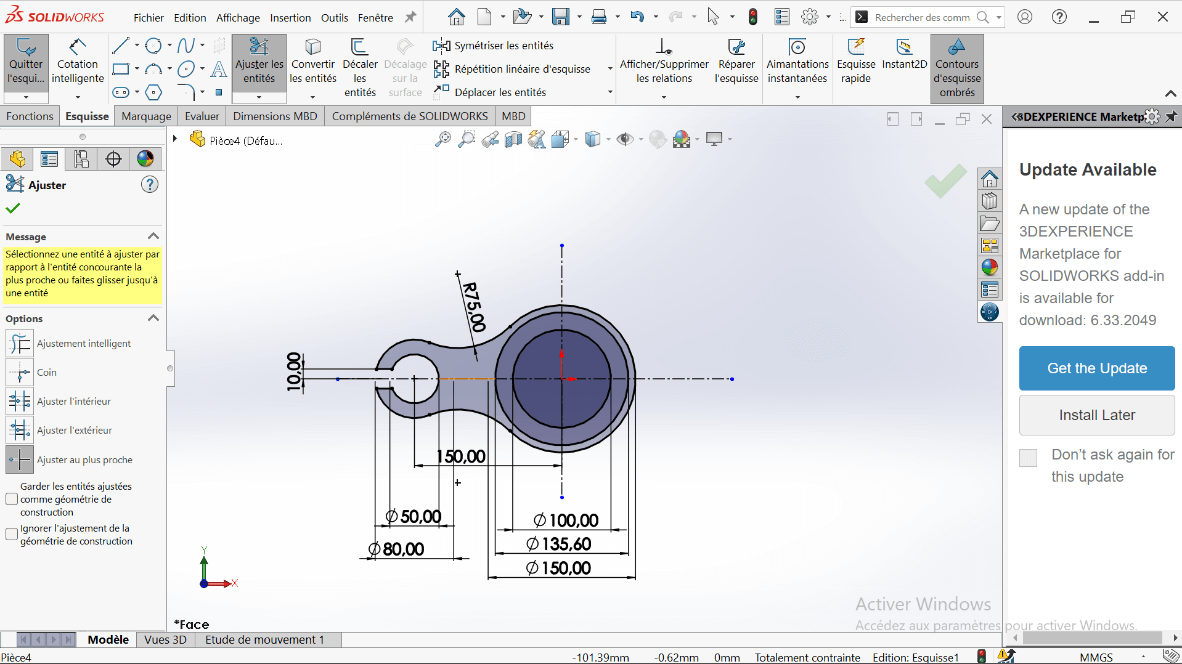

--> 3. Creating Fillet and Cutout

---> a. Create Tangent Arc

- Use the Perimeter Circle to draw a circle tangent to the 150 mm and 80 mm circles.

- Set the appropriate diameter to represent a 75 mm fillet.

- Use the Trim Entities tool to remove excess lines, forming a closed contour.

---> b. Offset the Arc

- Select the arc and apply a 10 mm offset using Offset Entities.

- Trim intersecting entities to clean up the sketch.

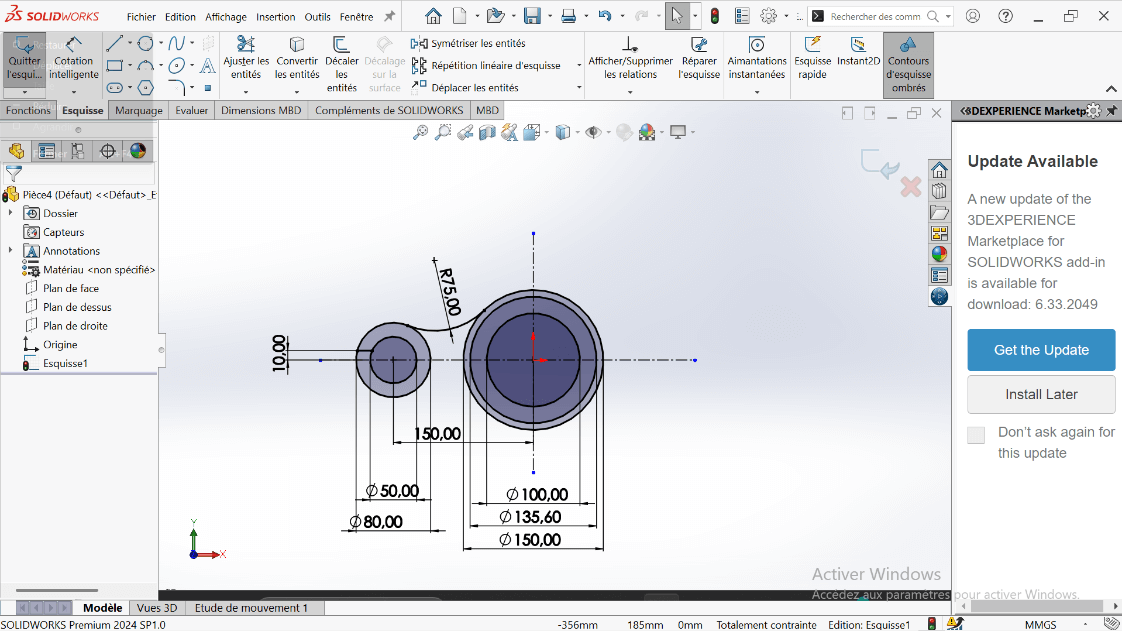

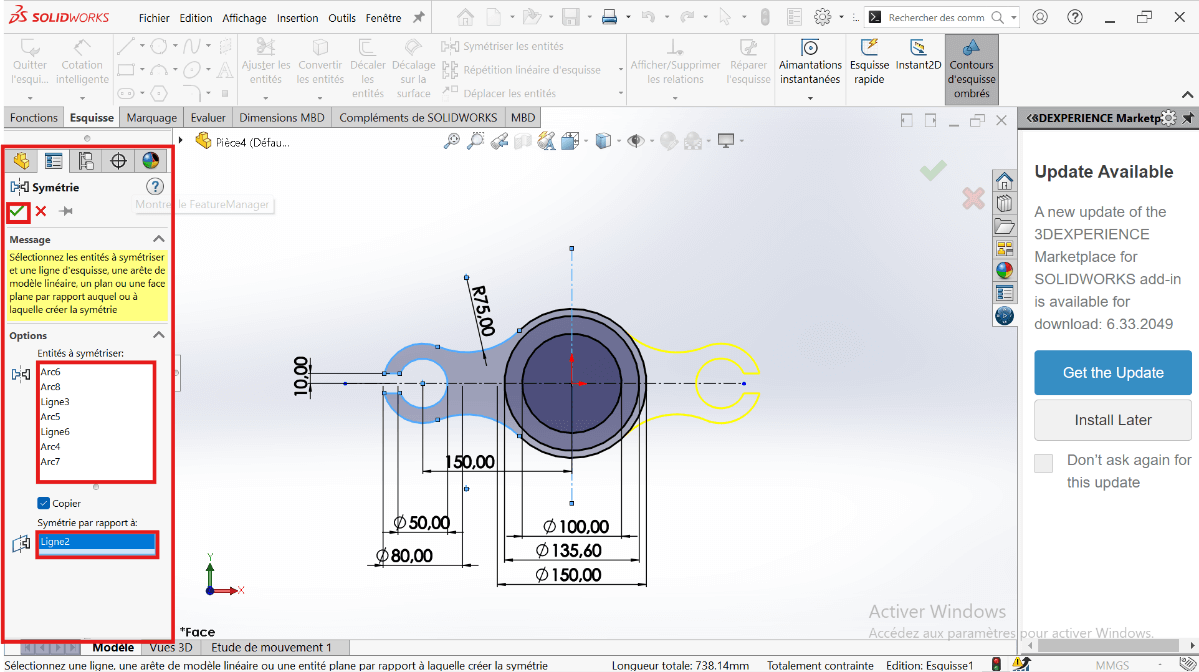

---> c. Mirror the Cutout

- Use Mirror Entities to duplicate the feature across the horizontal axis.

- Then mirror the resulting shapes across the vertical axis for full symmetry.

.

.

- Ensure the sketch forms a closed loop.

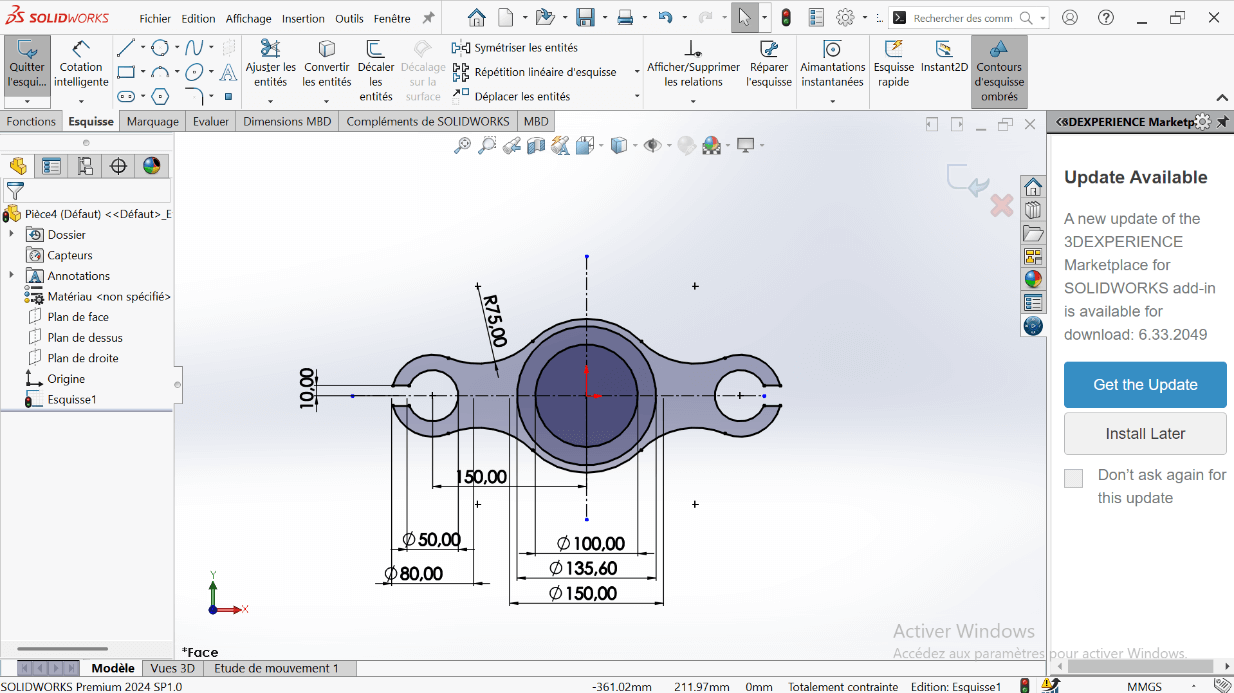

--> Creating the 3D Volume

-

Exit the sketch and switch to the Features tab.

-

Use Extruded Boss/Base:

- Select the entire sketch.

- Choose Blind extrusion with a depth of 20 mm.

- Select only the 100 mm diameter region to extrude the solid part.

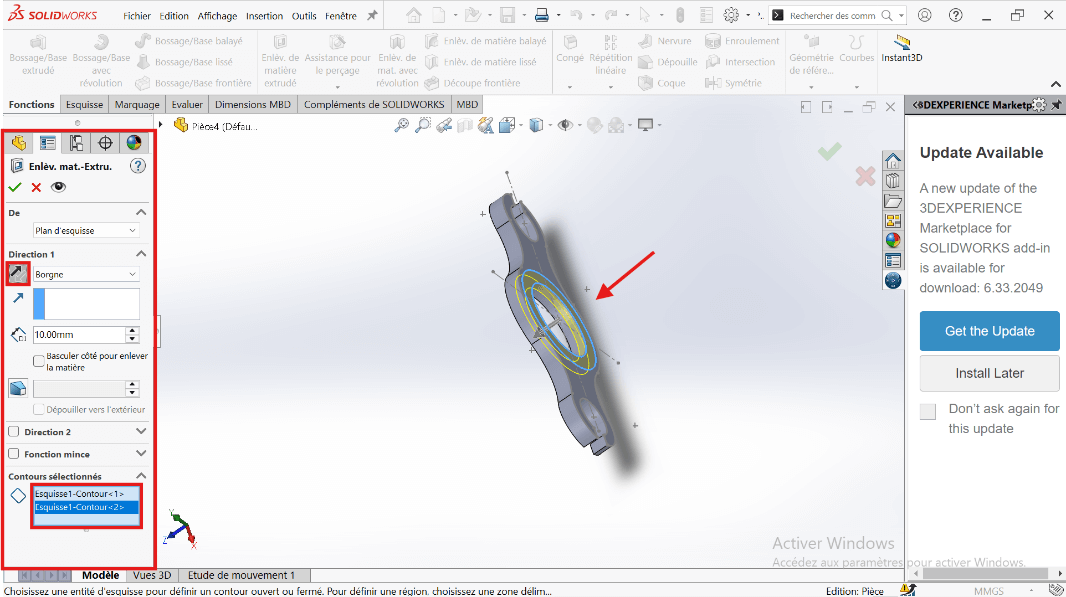

--> 5. Adding the Cut (Counterbore)

- Use Extruded Cut on the same sketch:

- Set cut depth to 10 mm.

- Select the region between 100 mm and 135.6 mm circles as the cut profile.

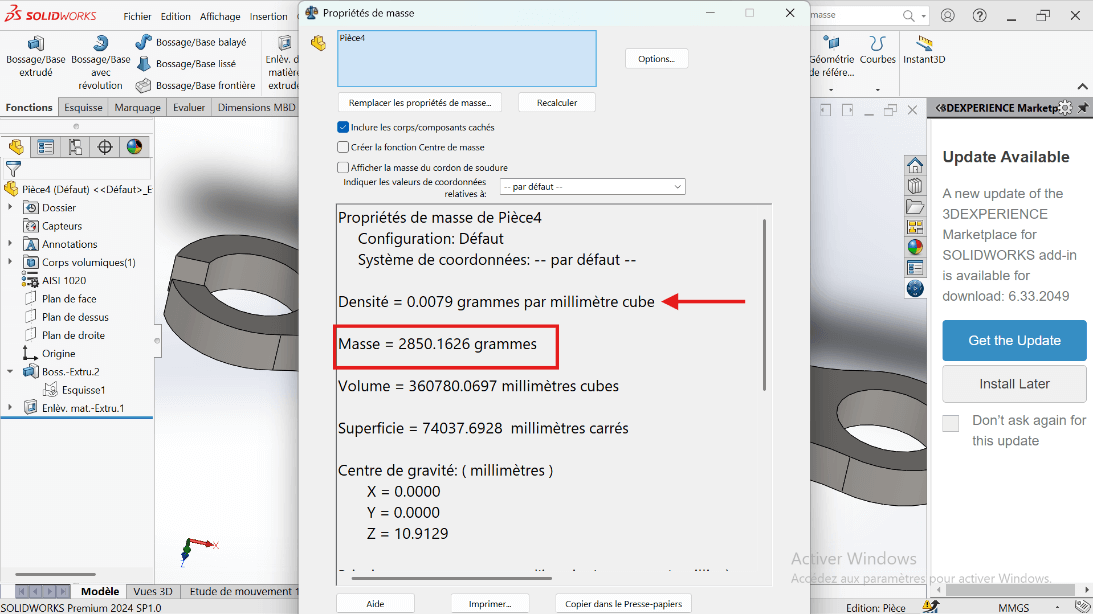

--> 6. Mass Evaluation

- Type Mass in the search bar.

- Click on Mass Properties.

The part mass should be 2850.16 grams.

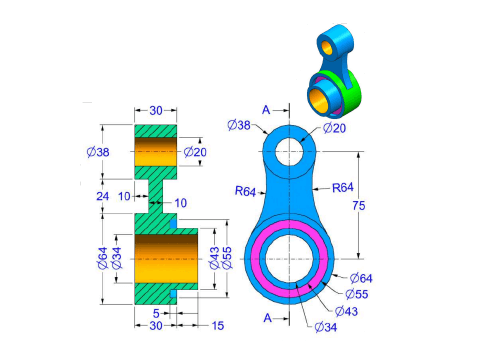

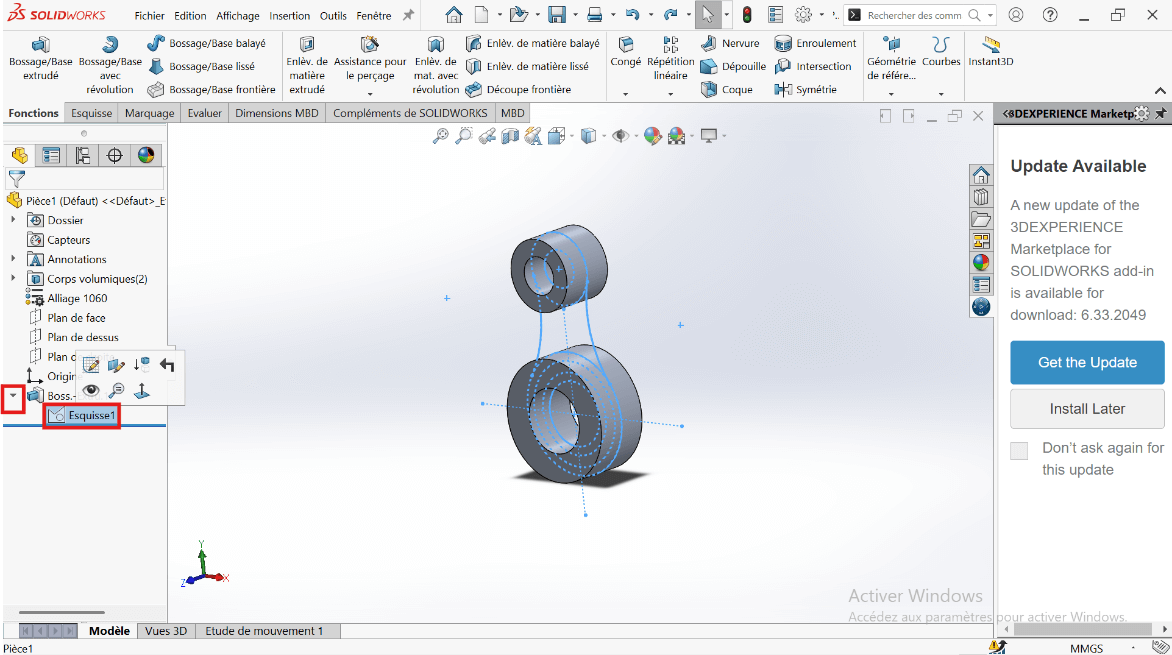

Modeling of the Second Part

Unit Systems and Material Properties

- MMGS (Millimeter, Gram, Second)

- Decimals: 2

- Hole Specification: All holes are through unless otherwise specified

- Material: Aluminum Alloy 1060

- Density: 0.0027 g/mm³

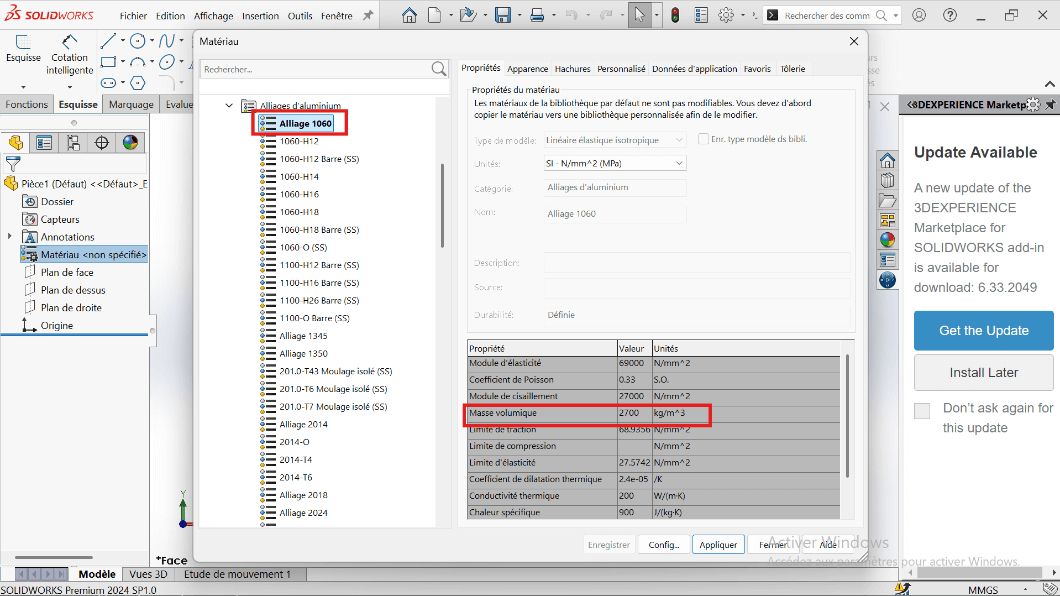

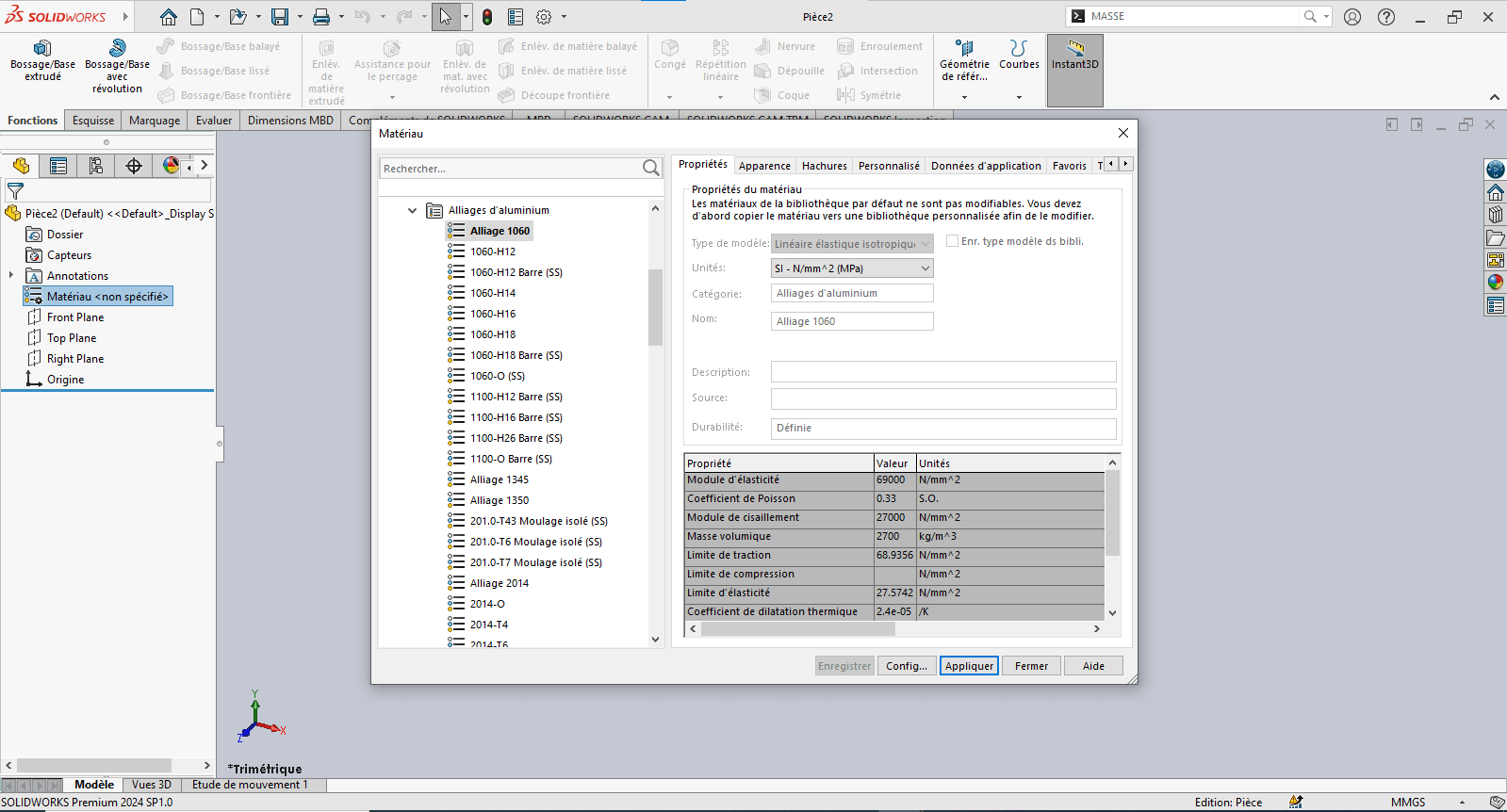

--> 1. Modifying Part 2 Parameters

- Right-click on Material: "Not Specified".

- Click on Edit Material.

- The Material tab opens.

- Navigate to SolidWorks Materials → Aluminum Alloy → Alloy 1060.

- Click Apply and Close.

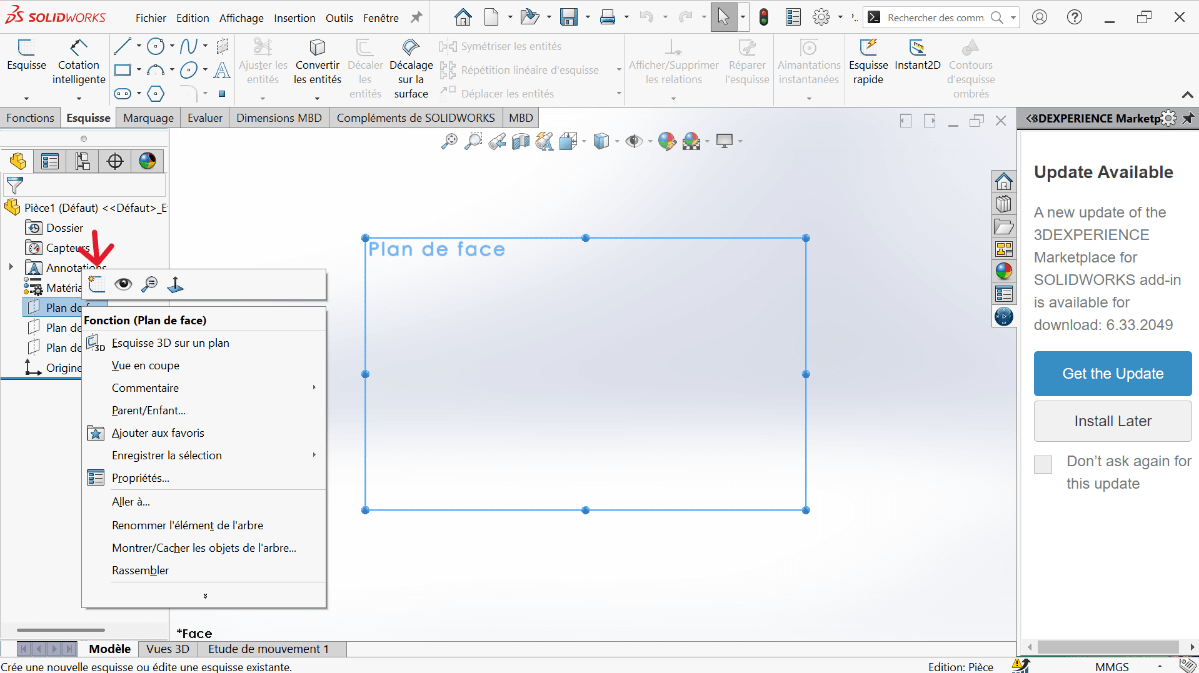

--> 2. Preparing the Workspace

- Click on Front Plane.

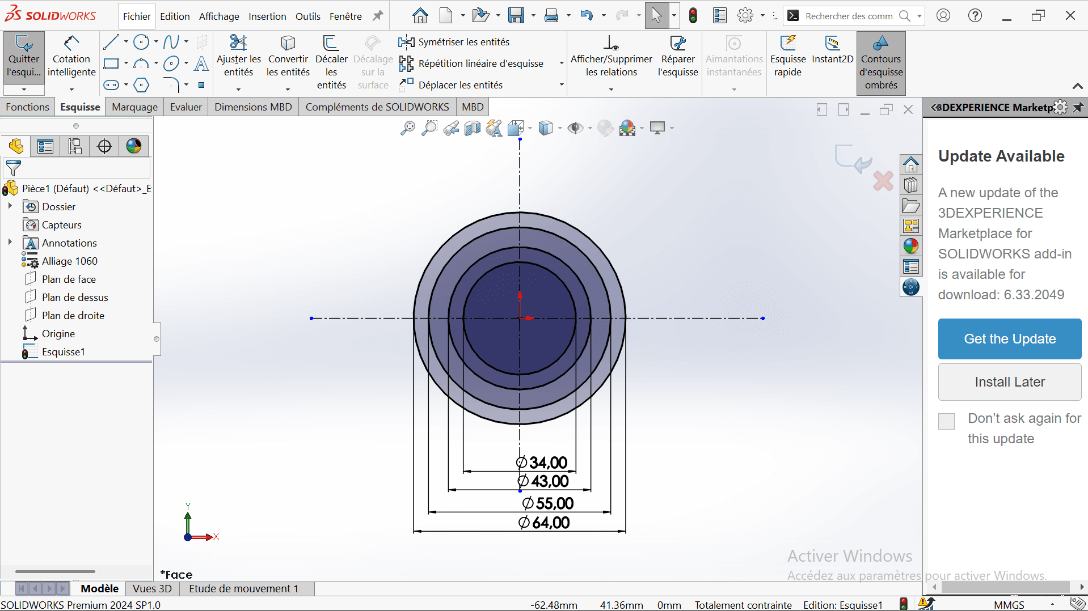

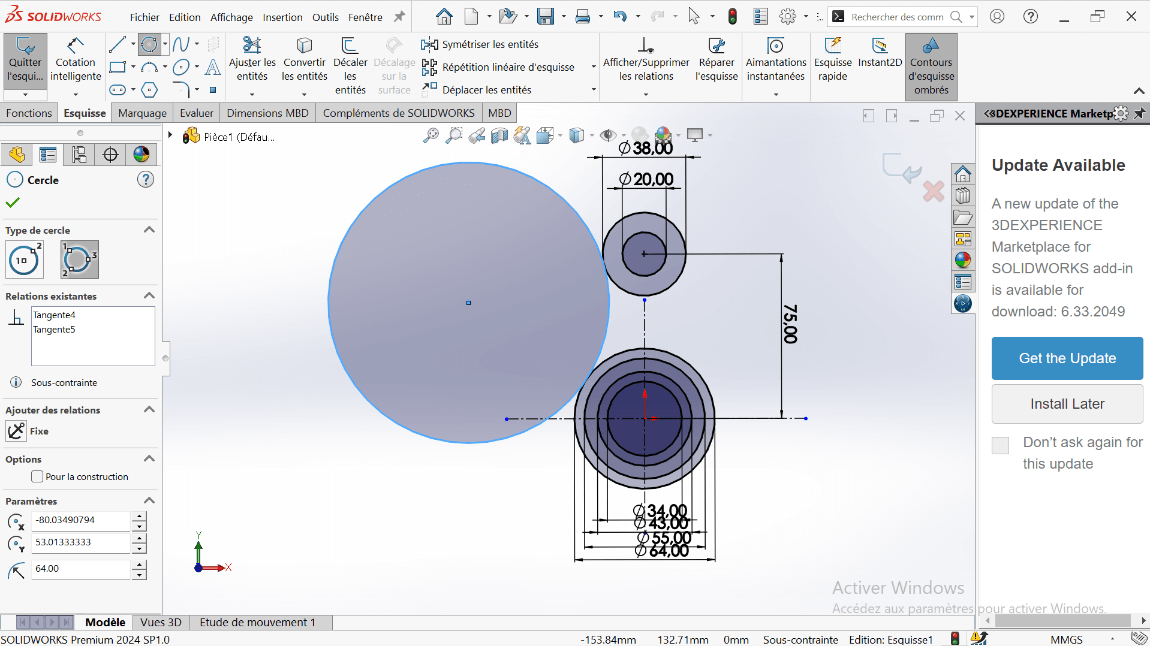

--> 3. Sketch Creation

- Click on the Circle tool and draw concentric circles with diameters 20 mm and 38 mm, centered on the vertical axis.

- Click on Smart Dimension:

- Select the 64 mm and 38 mm diameter circles.

- Specify the center distance as 75 mm and validate.

- Right-click on the Circle tool and select Perimeter Circle.

- Select the entities:

- Click on the 64 mm and 38 mm diameter circles.

- Click on an external point (the created circle will be tangent to the selected circles).

- Specify the fillet radius as R64.

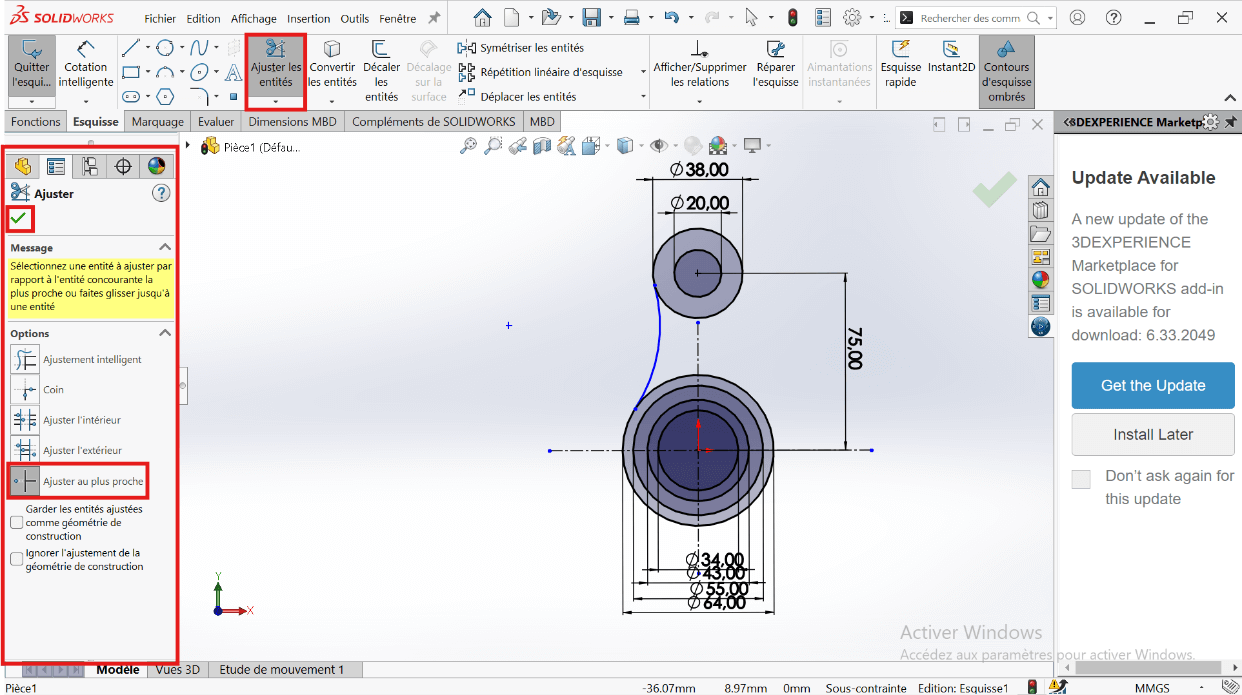

- Click on the Trim Entities tool to remove overlapping sketch parts and create a closed sketch.

- Select the Trim tool properties.

- Click on the entities to remove.

- Apply the dimensioning to the fillet.

- Click on the Symmetry tool.

- Select the entities to symmetrize: R64 fillet.

- Select the symmetry axis: Vertical axis.

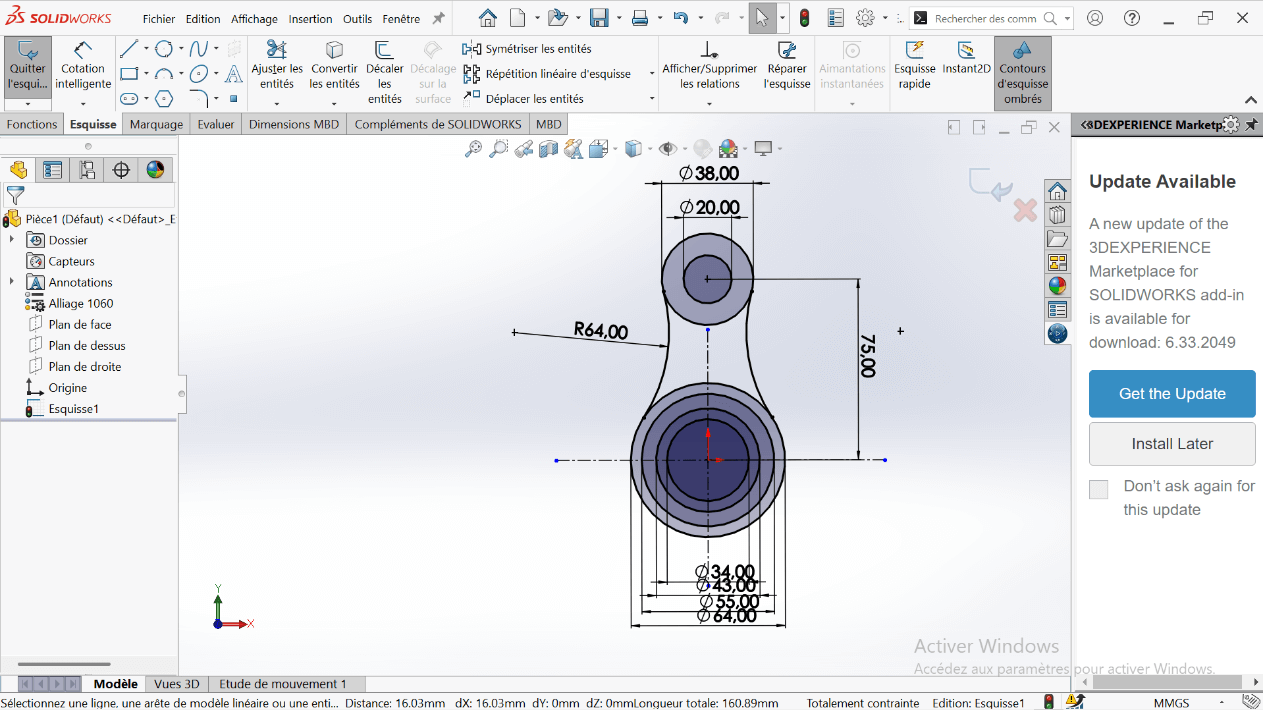

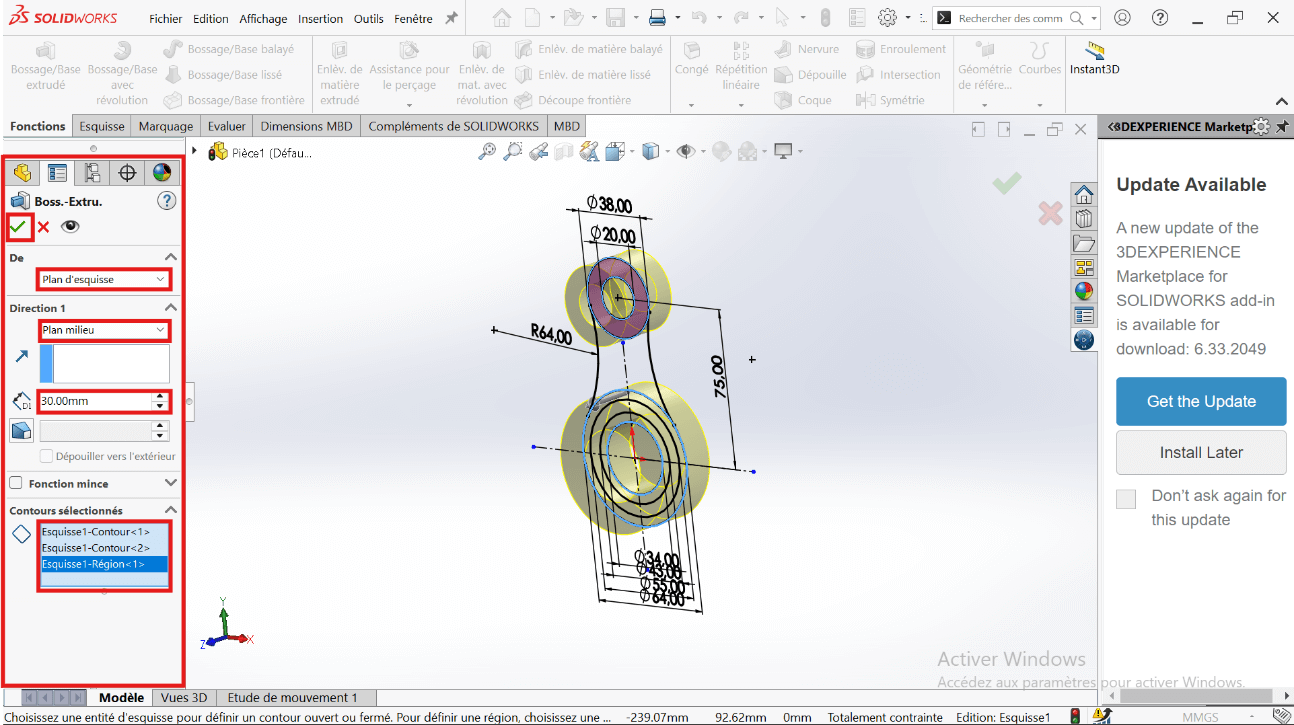

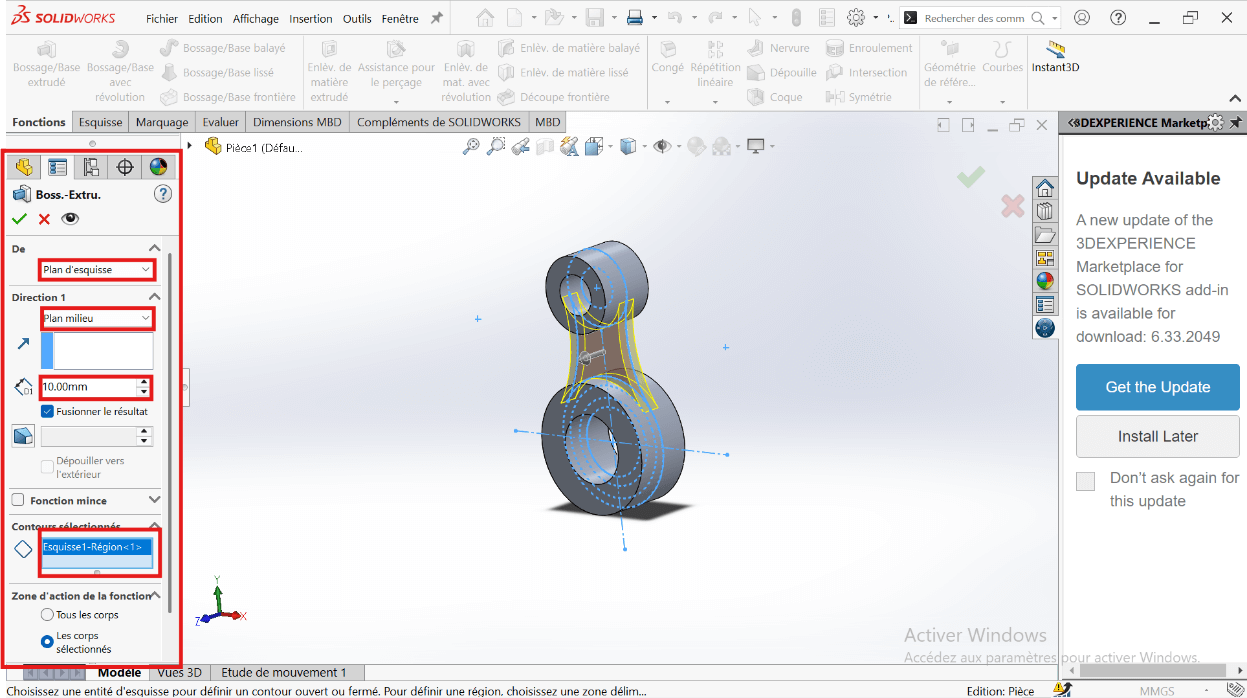

--> 3. Creating the Volume

- Click on Features → Extruded Boss/Base.

- Select the entities to extrude.

- Click Validate.

- Click on Boss/Base → Sketch.

- Click on Features → Extruded Boss/Base.

- Select the entities to extrude.

- Click Validate.

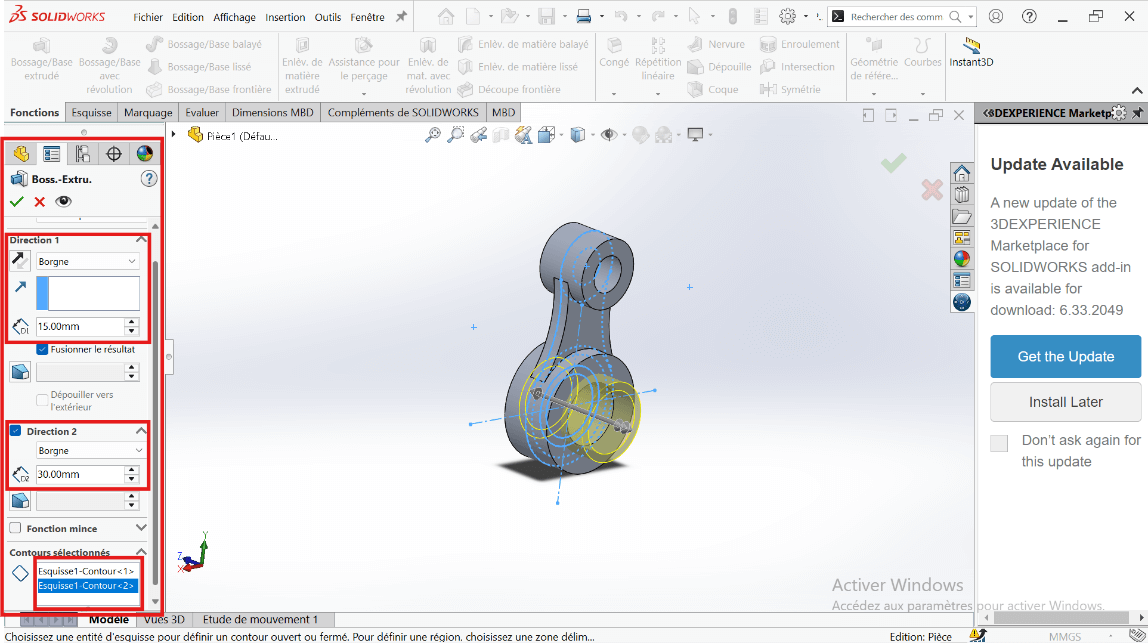

- Click on Boss/Base → Sketch → Extruded Boss/Base.

- Select the entities to extrude: 43 mm and 34 mm diameter circles.

- In the parameters, select Direction 1 and Direction 2.

- Specify the extrusion distances: 15 mm and 30 mm.

- Click Validate.

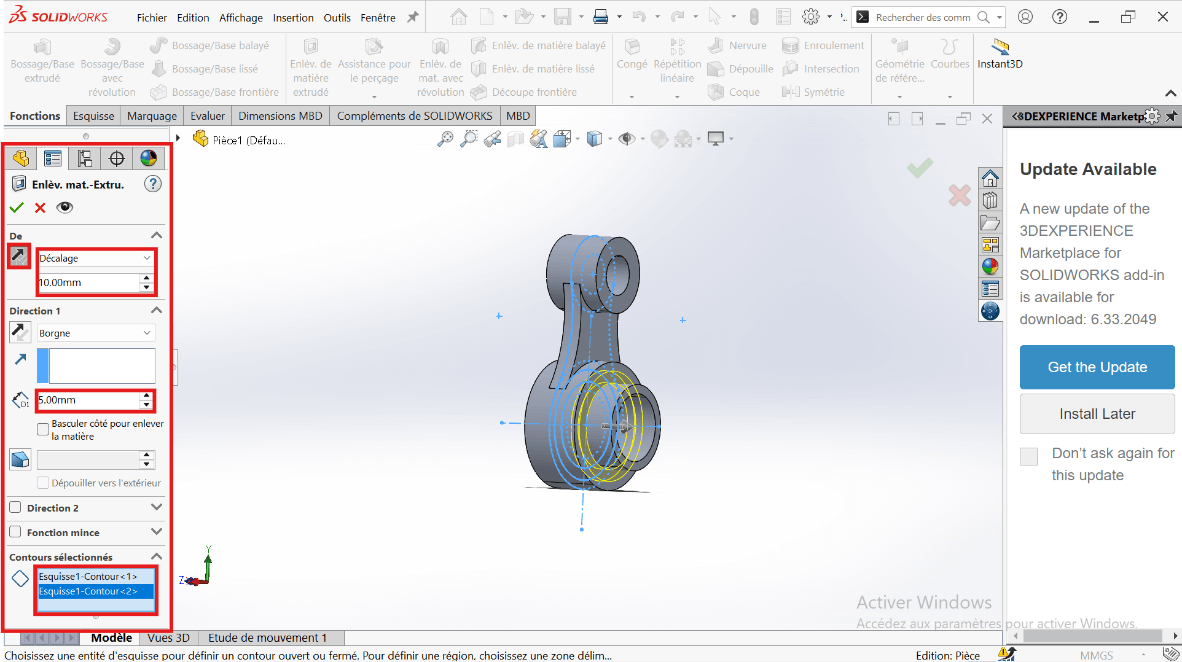

- Click on Boss/Base → Sketch → Extruded Cut.

- Select the entities to cut: 43 mm and 55 mm diameter circles.

- Click Validate.

--> 6. Mass Properties

- Mass Calculation: Use the Mass Properties tool to determine the part's mass.

The part mass is : 290.79 gramms

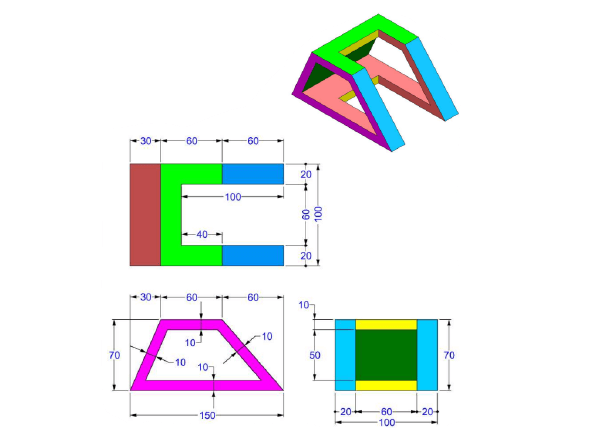

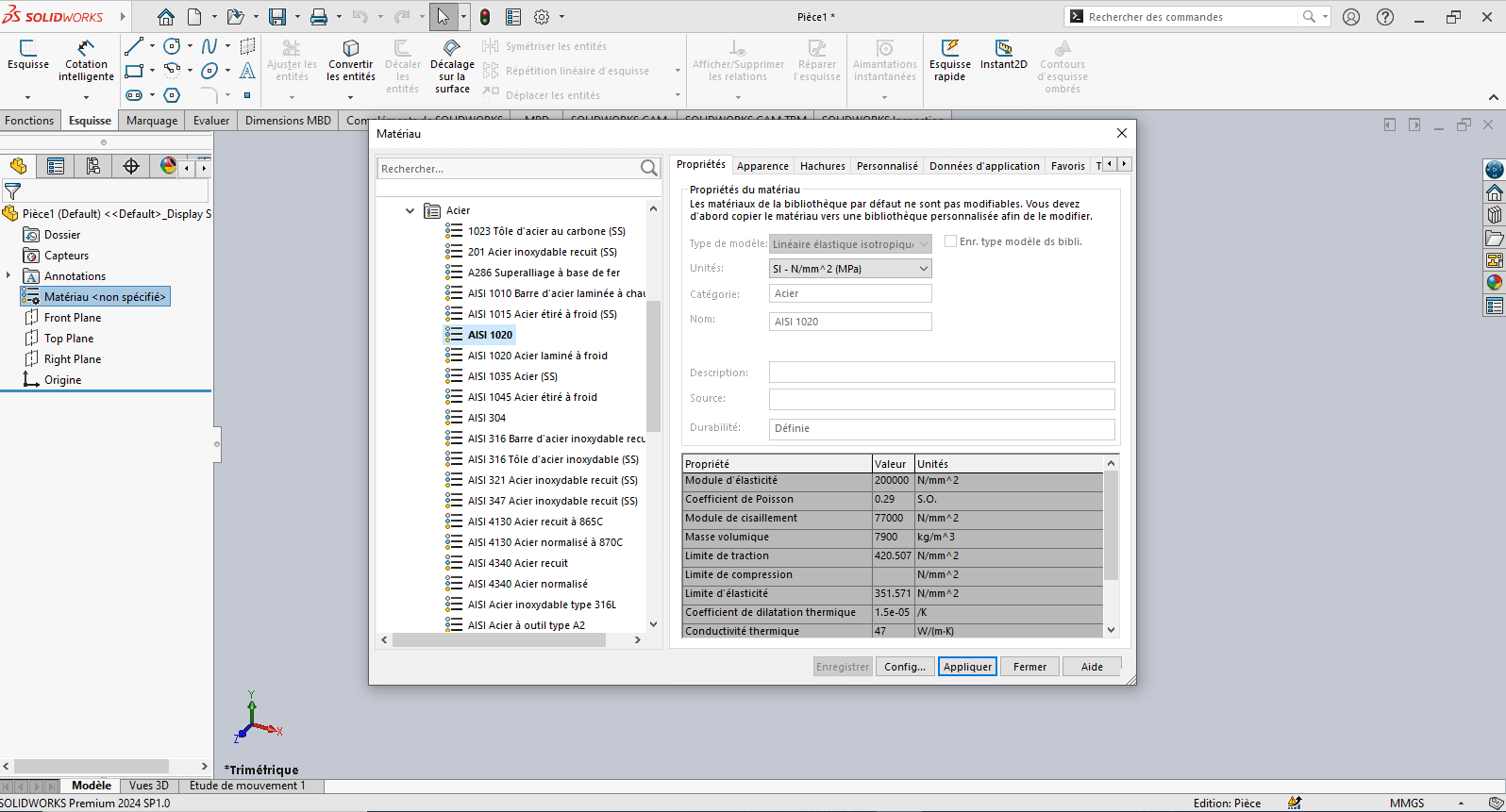

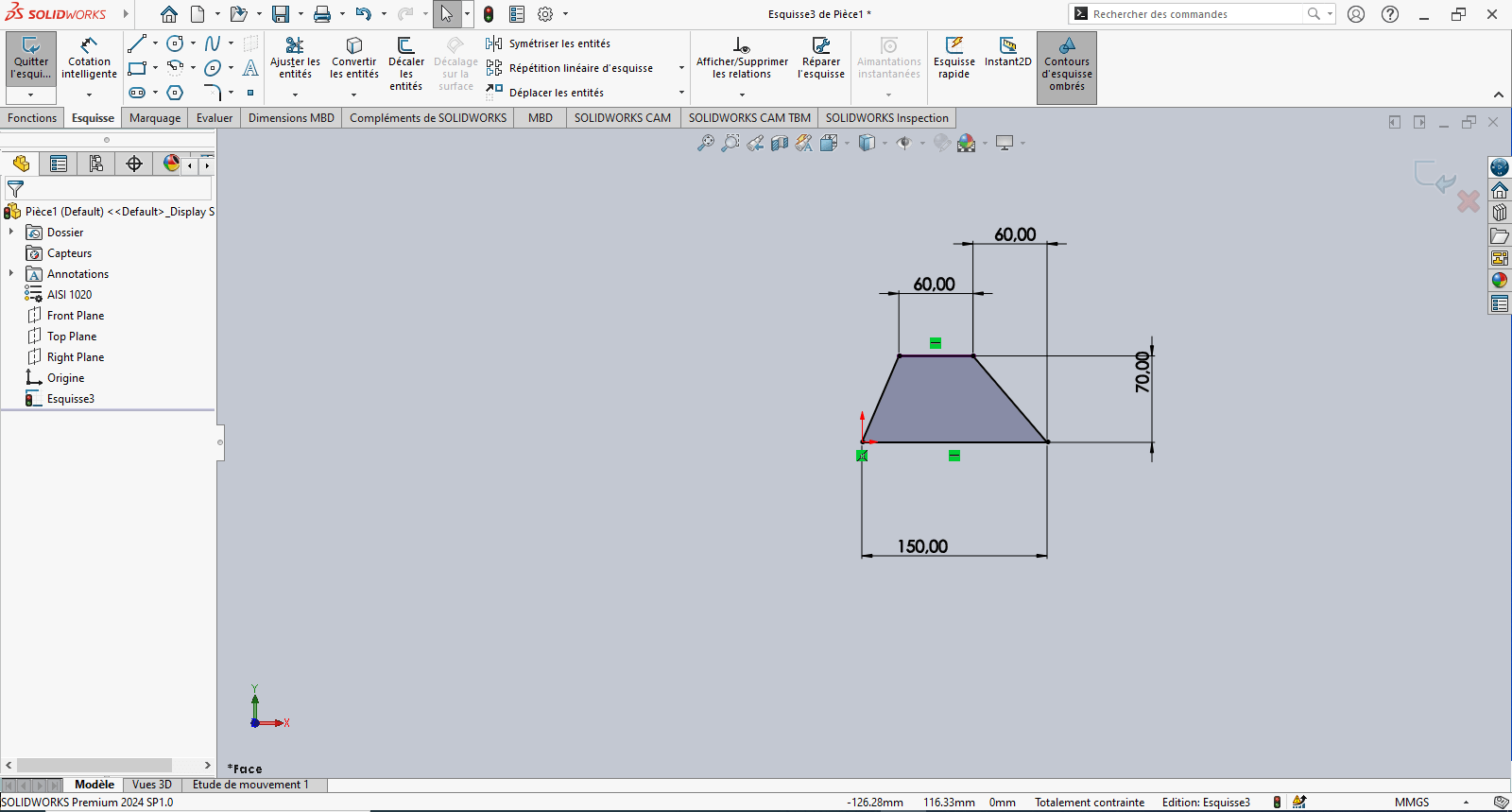

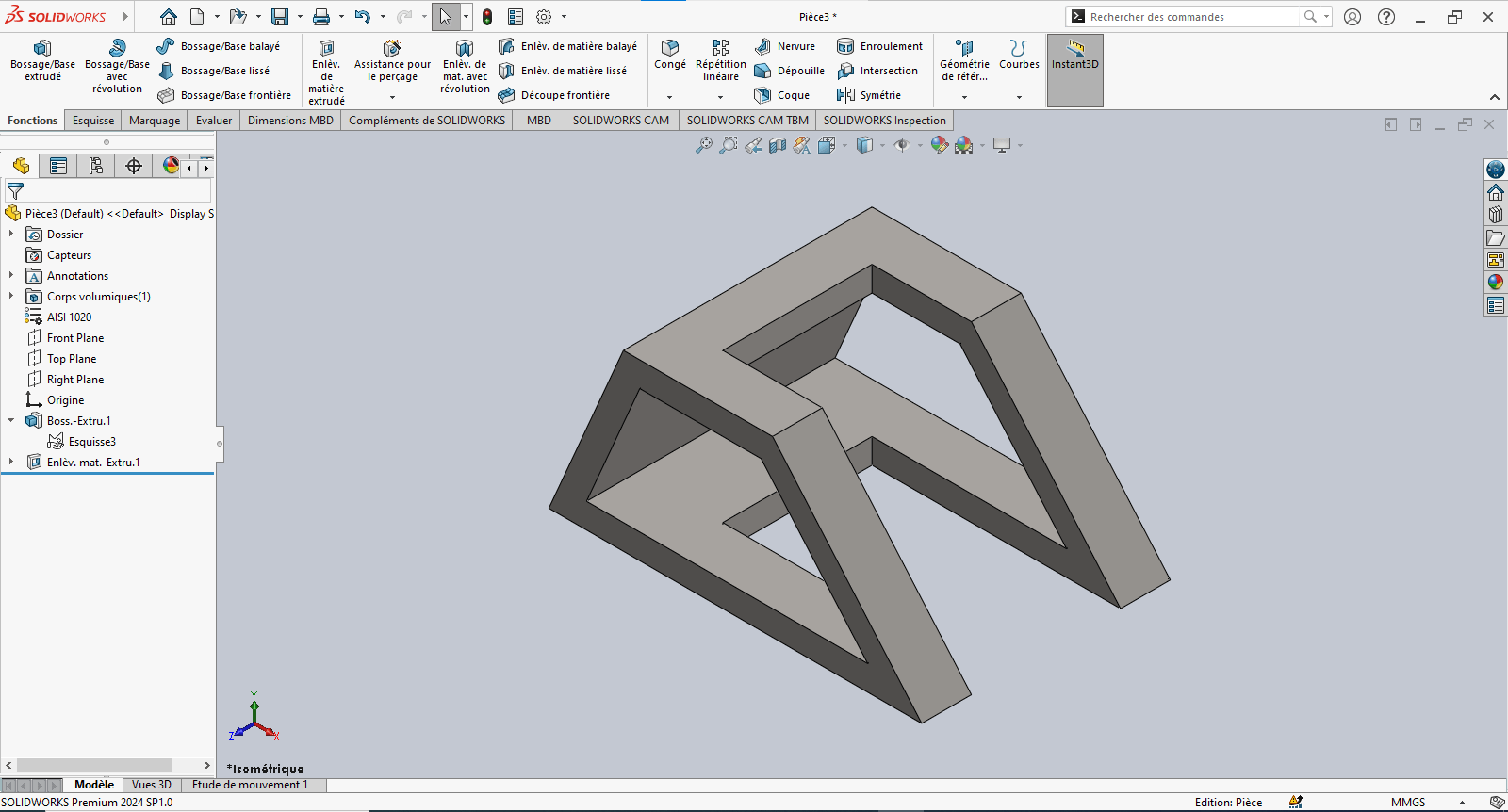

Modeling of the Third Piece

Unit System

- MMGS (Millimeter, Gram, Second)

- Decimals: 2

- Hole Specification: All holes are through unless otherwise specified

- Material: AISI 1020 Steel

- Density: 0.0079 g/mm³

--> 1. Modifying Part 3 Parameters

-

Right-click on Material: "Not Specified"

-

Select Edit Material

-

In the Material tab:

- Browse to SolidWorks Materials > Steel > AISI 1020

- Click Apply, then Close

-

Click on the Front Plane, then select Sketch

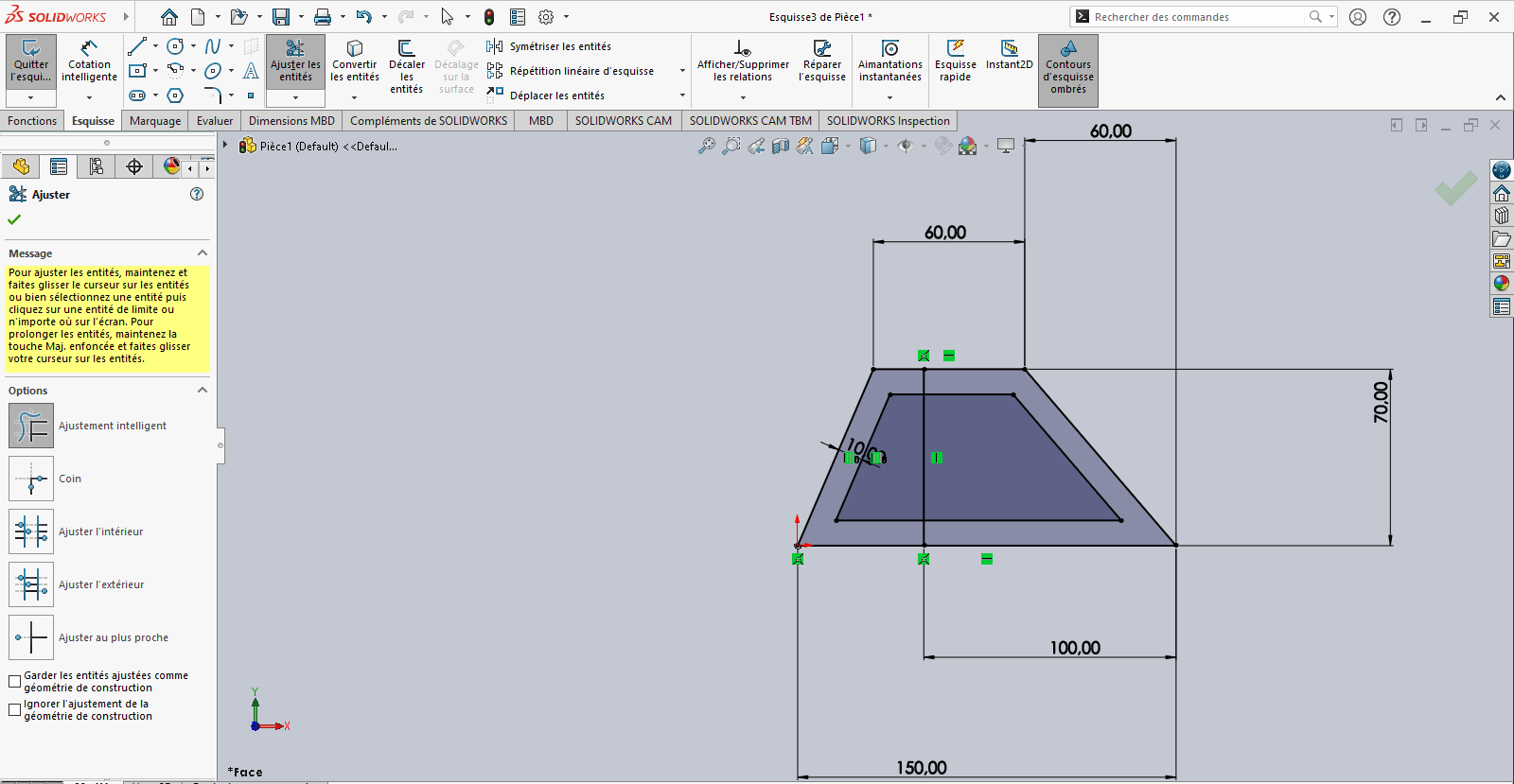

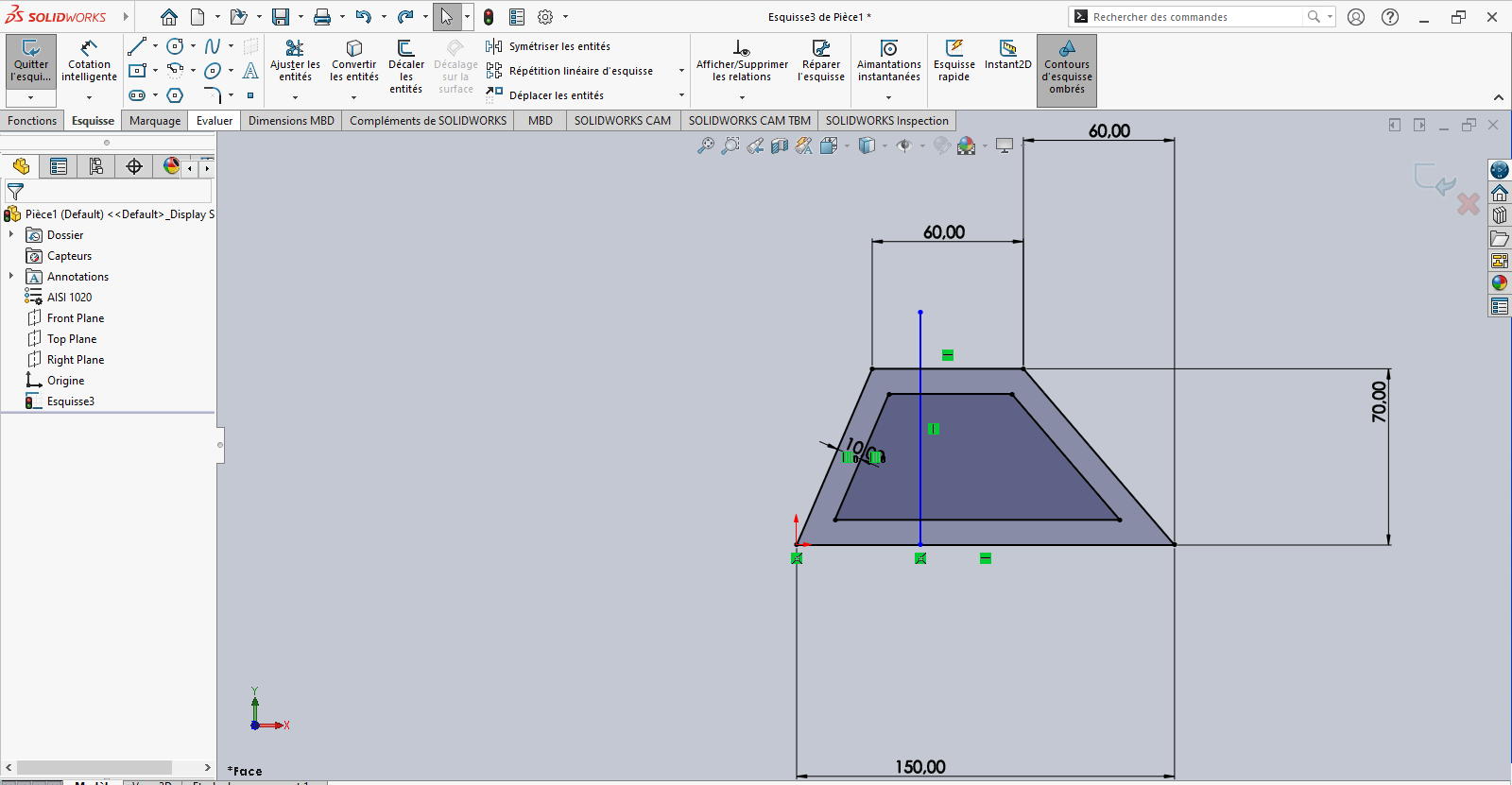

--> 2. Creating the Sketch

- Use the Line tool to draw a trapezoid (initial dimensions can be arbitrary)

- Use Smart Dimensioning to set precise dimensions

Tip: Reference the origin to fix the sketch and improve stability

- Use the Offset Entities tool to offset the trapezoid 10 mm inward

-

If the offset direction is incorrect, reverse it in the Property Manager

-

Use the Line tool again to draw a vertical line starting from the base of the 150 mm horizontal segment

- Apply Smart Dimensioning to position this line relative to a fixed reference point

- Verify that the sketch is fully constrained

- If not, apply necessary constraints to stabilize the geometry

- Exit the sketch

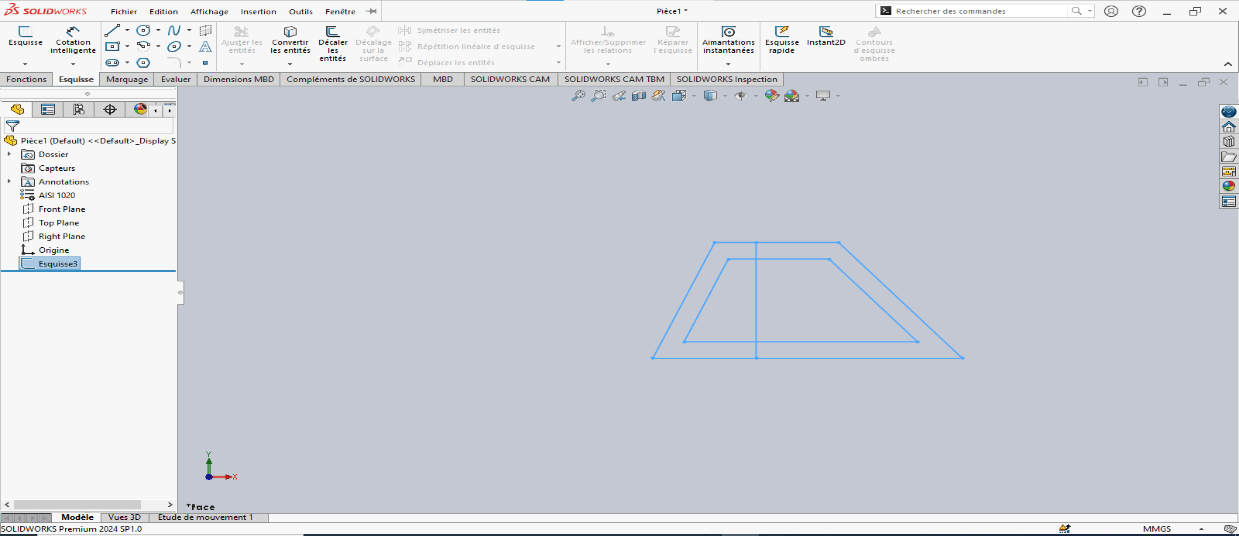

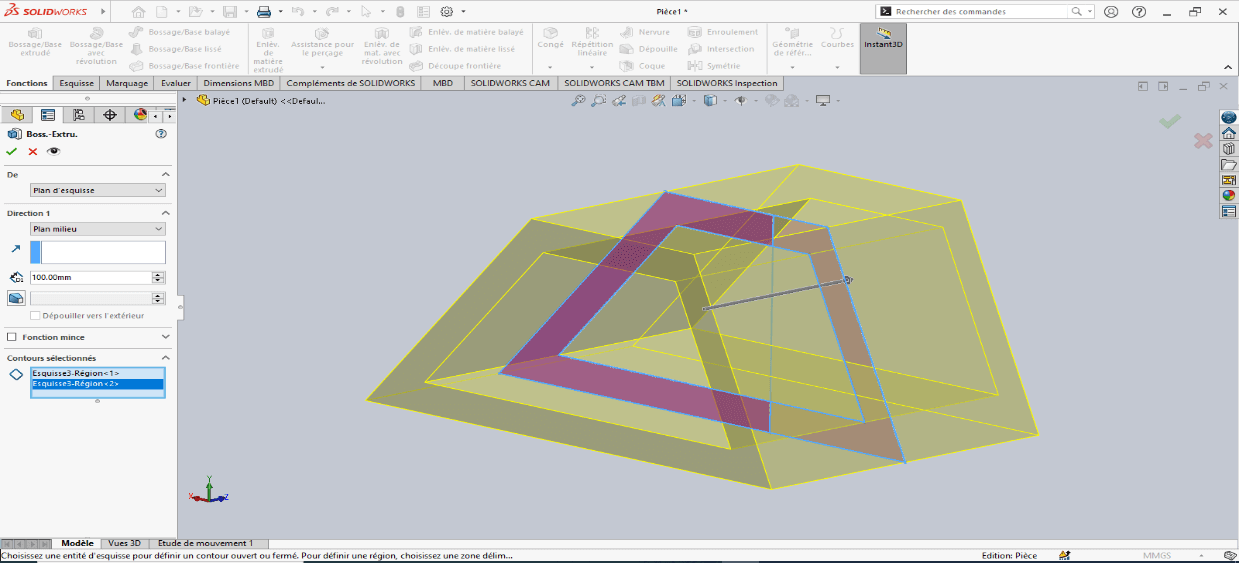

--> 3. Creating the 3D Volume

---> Boss-Extrude (Solid)

-

Navigate to Features > Extruded Boss/Base

-

Select the sketch entities to extrude

-

Set extrusion properties:

- Direction: Select Mid Plane

- Depth: 100 mm

-

Confirm by clicking OK

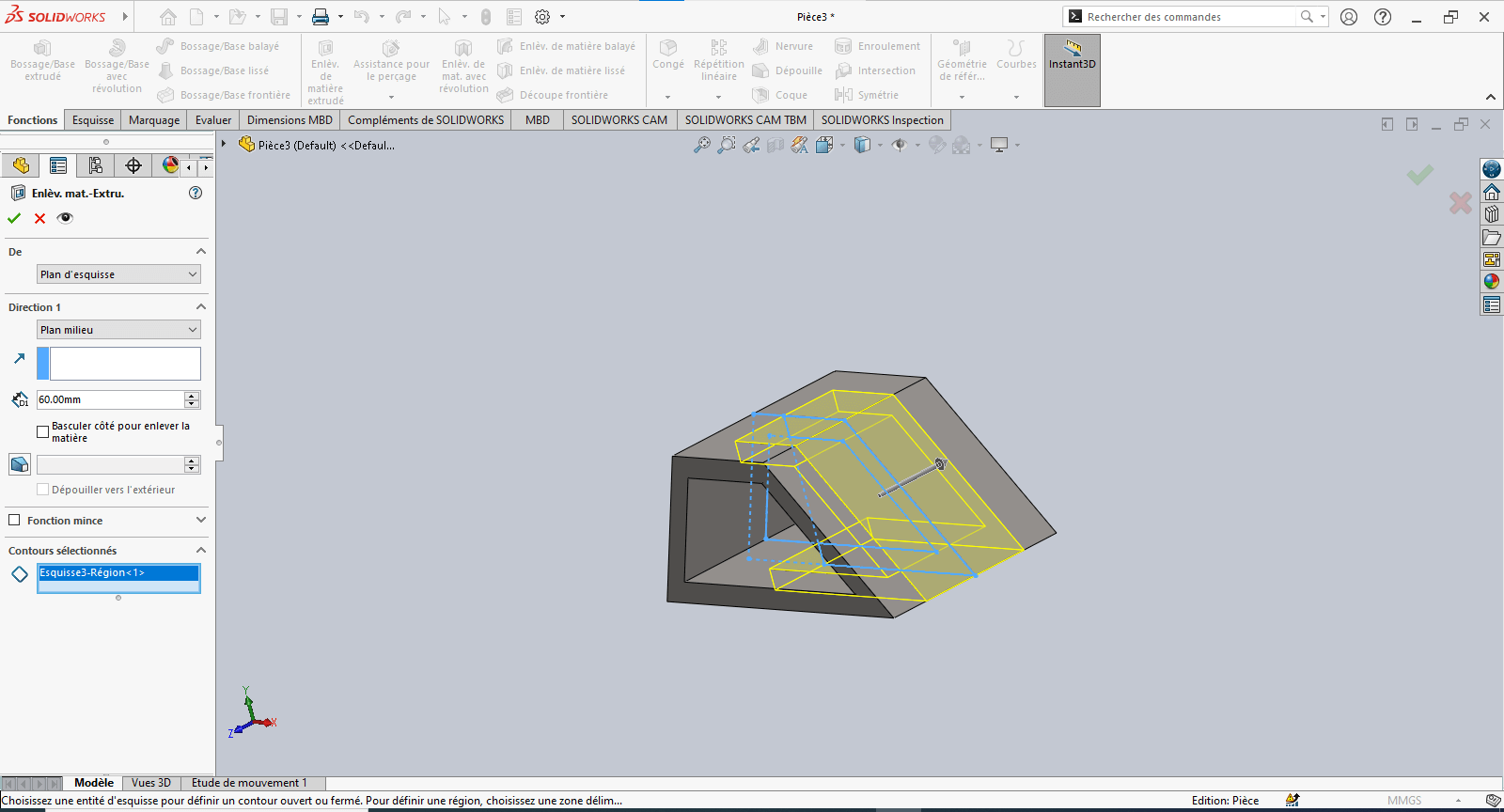

---> Cut-Extrude (Material Removal)

-

Select Extruded Cut

-

Choose the entities to remove

-

Set extrusion properties:

- Direction: Select Mid Plane

- Depth: 60 mm

-

Confirm by clicking OK

--> 4. Evaluating Part Mass

- Type "Mass" in the search bar

- Click on Mass Properties

- Review the calculated mass based on geometry and material assignment

The piece mass is : 1633.25 gramms

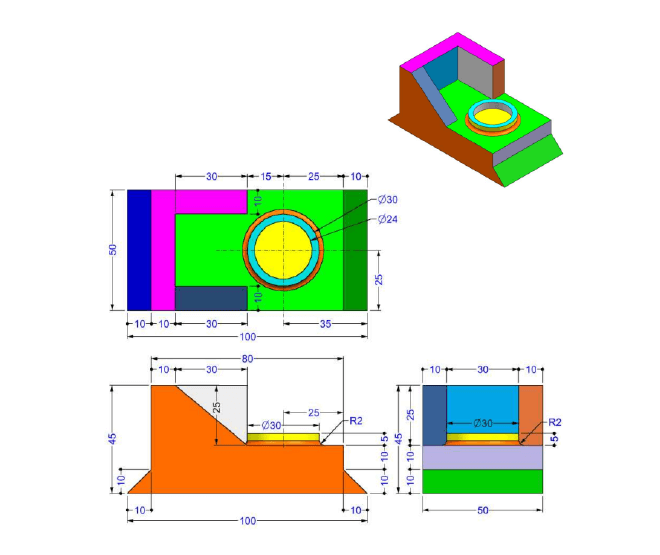

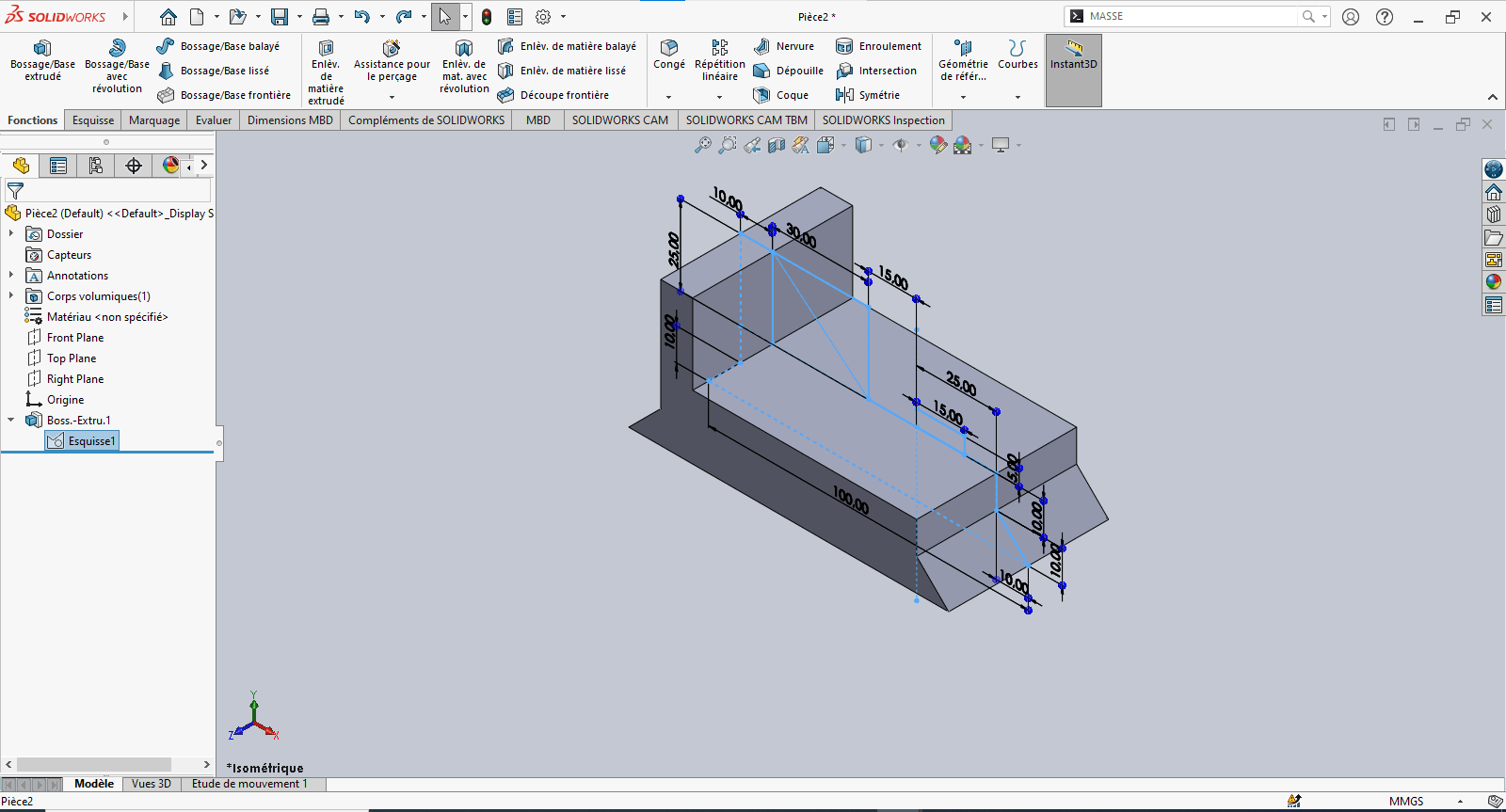

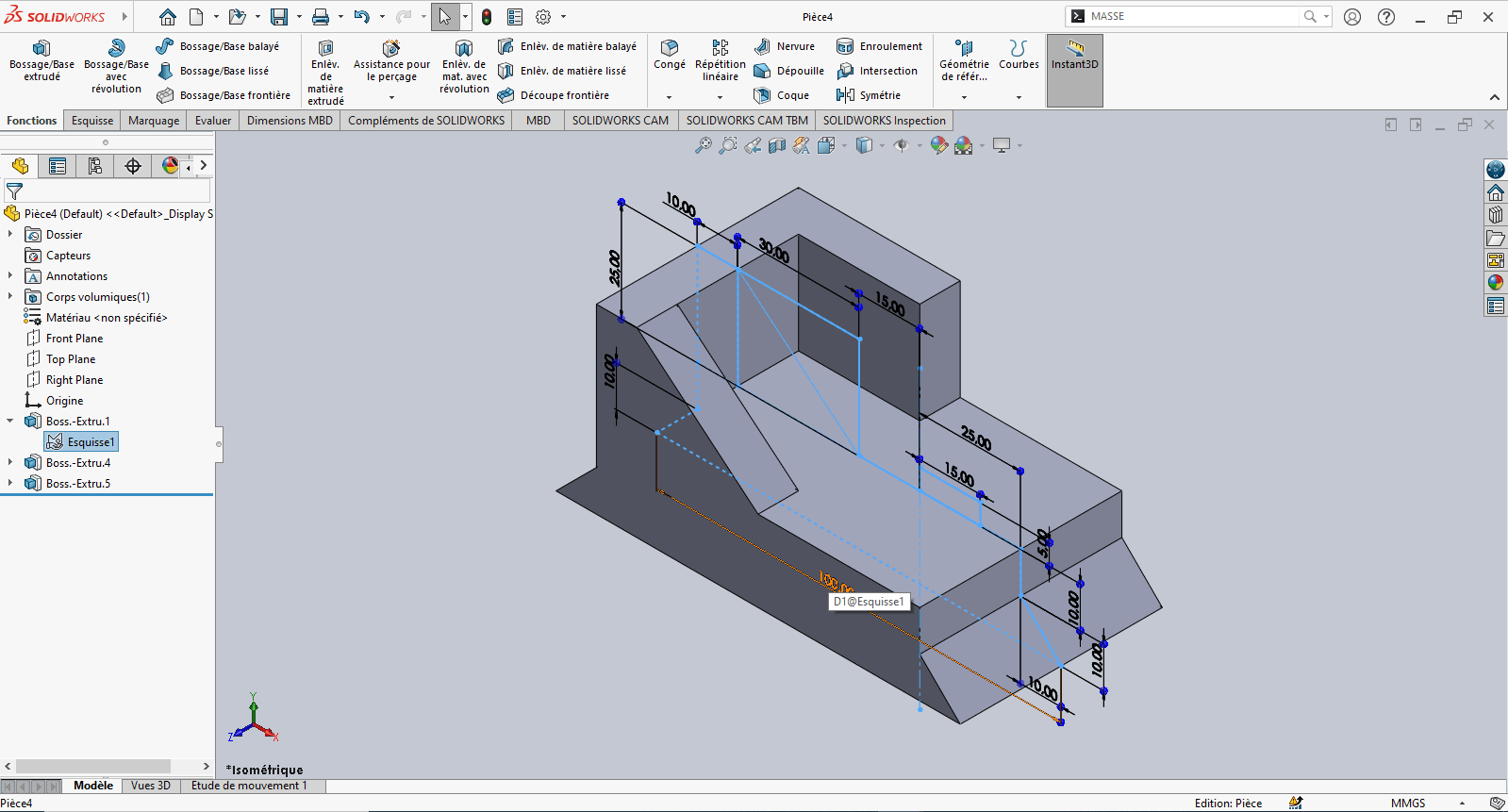

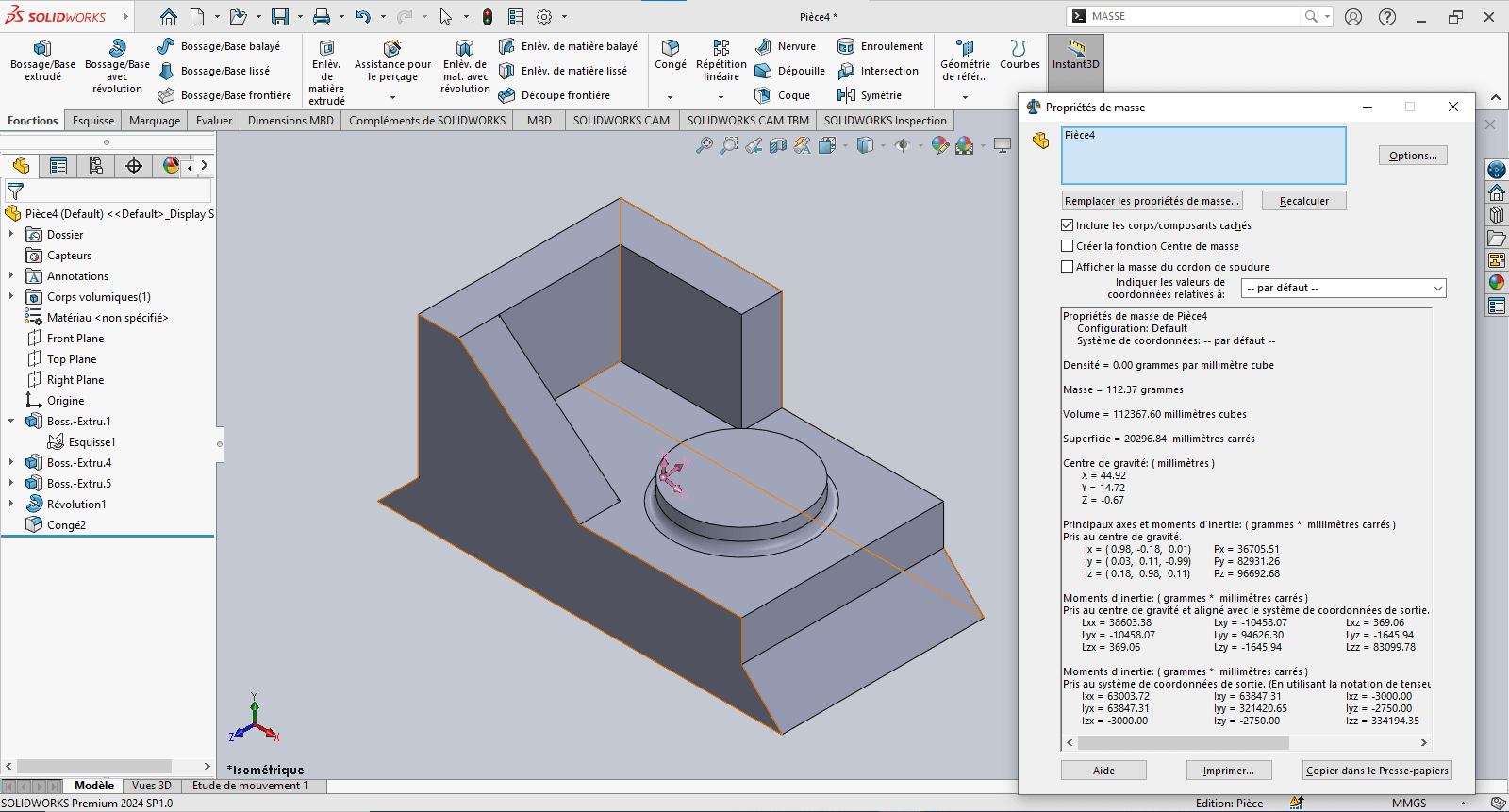

Modeling of the Fourth Piece

Unit System

- MMGS (Millimeter, Gram, Second)

- Decimals: 2

- Hole Specification: All holes are through unless otherwise specified

- Material: Aluminum Alloy 1060

- Density: 0.0027 g/mm³

--> 1. Updating Material Settings

- Right-click on Material: “Not Specified”

- Select Edit Material

- In the Material tab:

- Navigate to SolidWorks Materials > Aluminum Alloys > 1060 Alloy

- Click Apply, then Close

--> 2. Preparing the Workspace

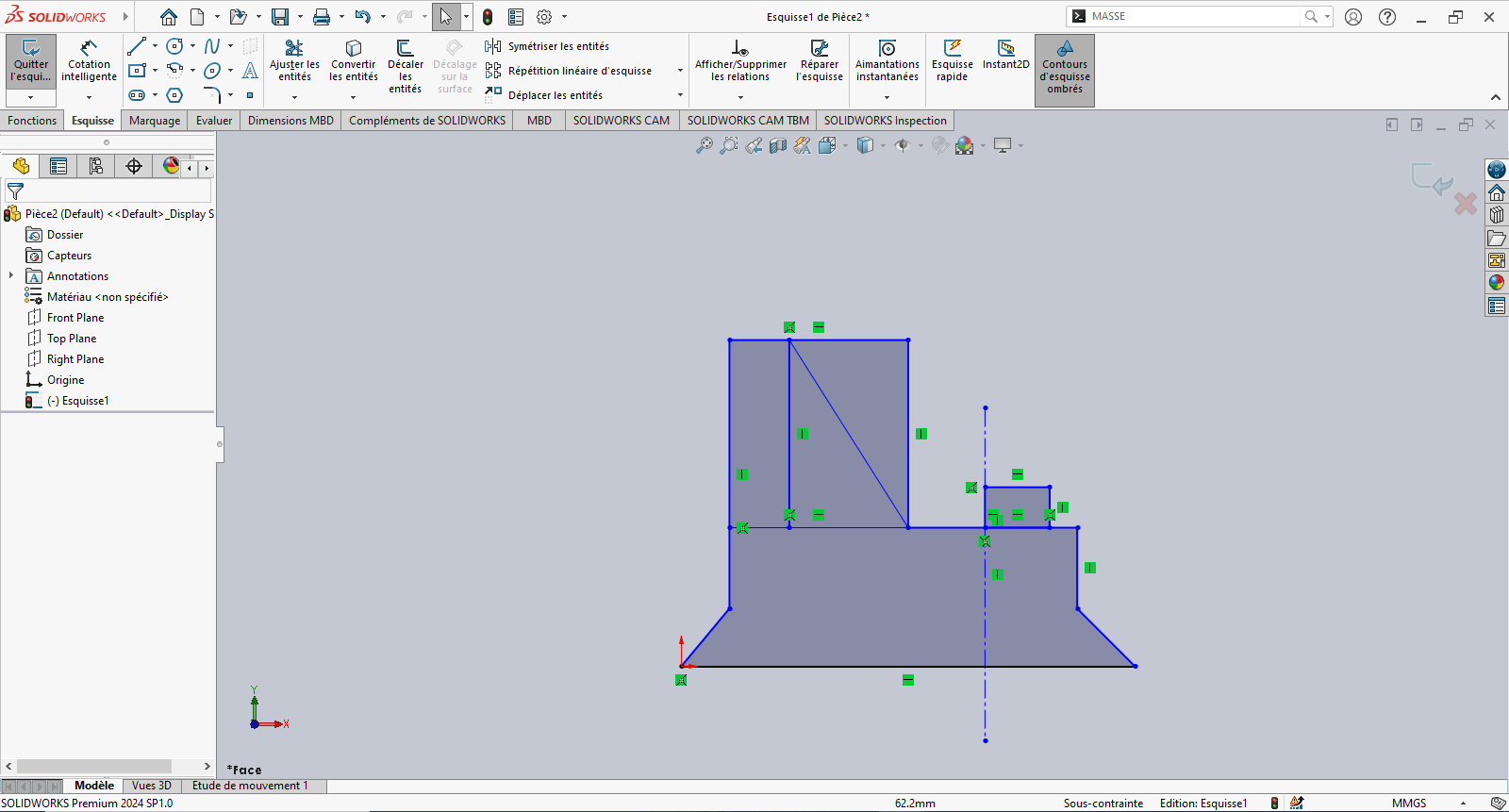

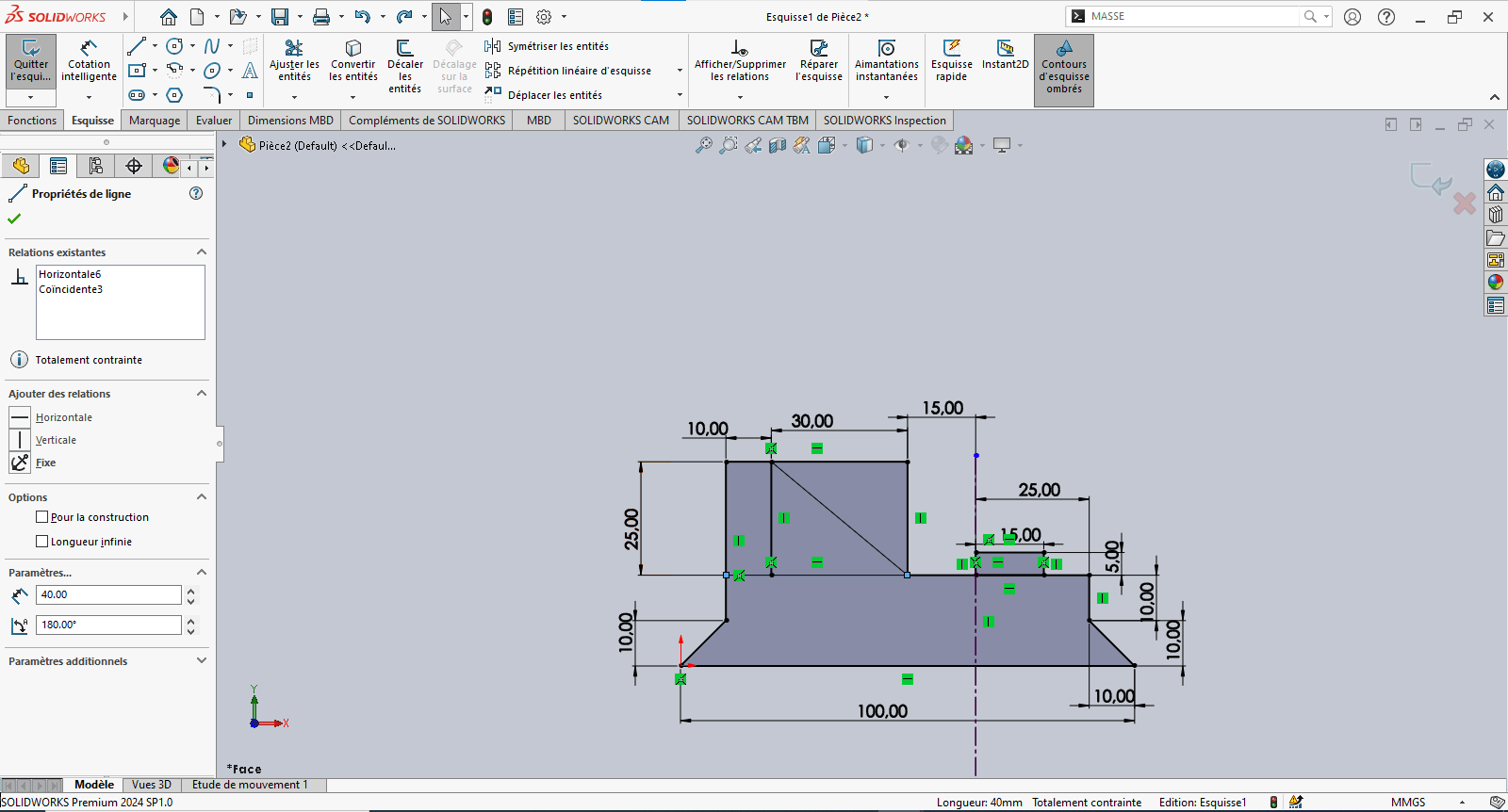

- Select the Front Plane and click Sketch

--> 3. Creating the Sketch

- Use the Line tool to draw a profile similar to the front view of the part

- Use Smart Dimension to assign dimensions to the sketch elements

- Reference the origin wherever possible for stability

- Exit the sketch

--> 4. Creating the Volume – Extrusions

---> First Extrusion

- Click Features > Extruded Boss/Base

- In the Feature Manager:

- Set extrusion direction to Mid Plane

- Set Depth to 50 mm

- Select the appropriate contour and confirm

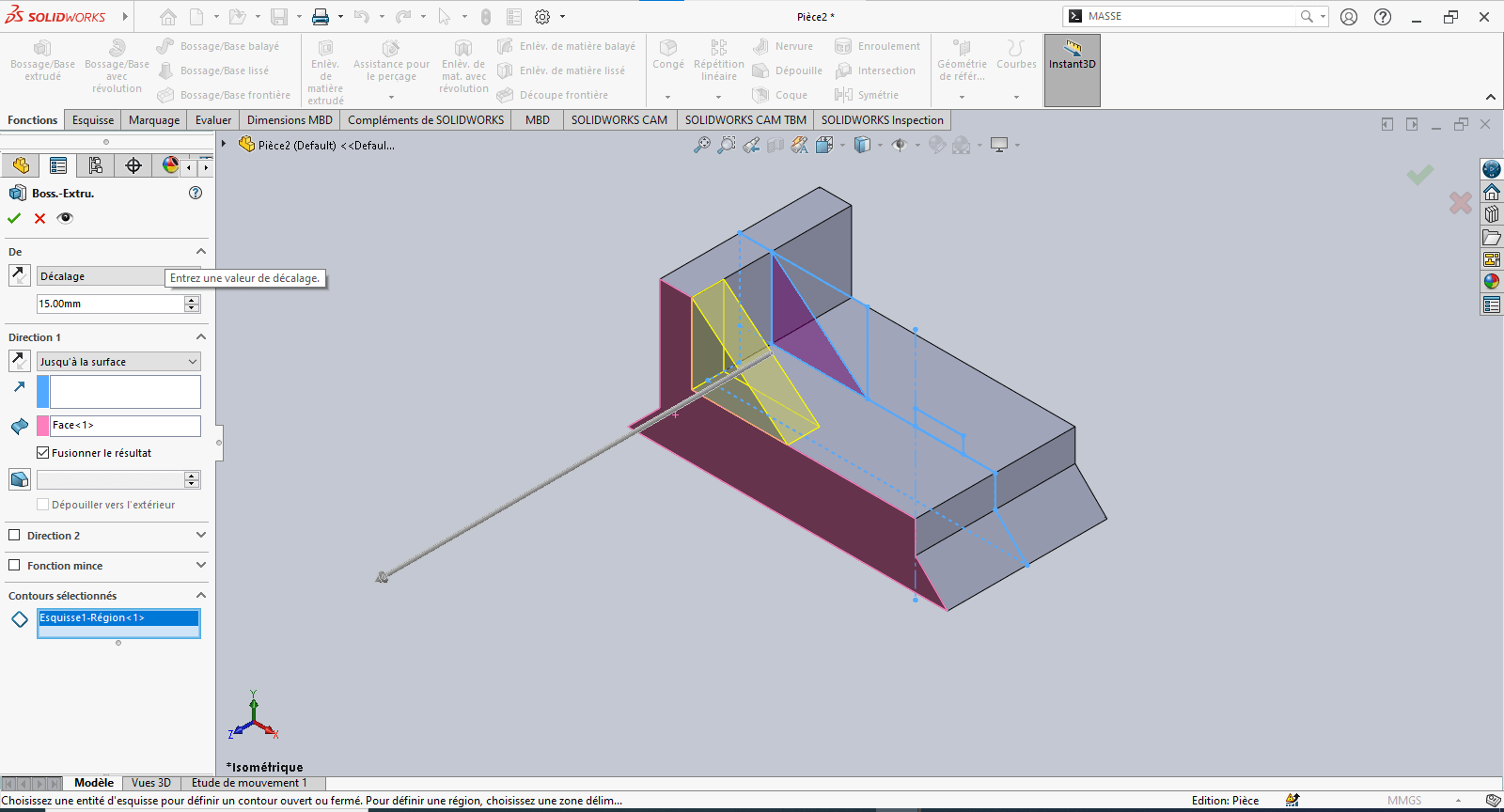

---> Second Extrusion

-

Return to the same sketch

-

Click Extruded Boss/Base

- Set an offset of 15 mm

- Define the direction carefully (flip if needed)

- Choose Up to Surface as the end condition if required, and select the target face

-

Validate the extrusion

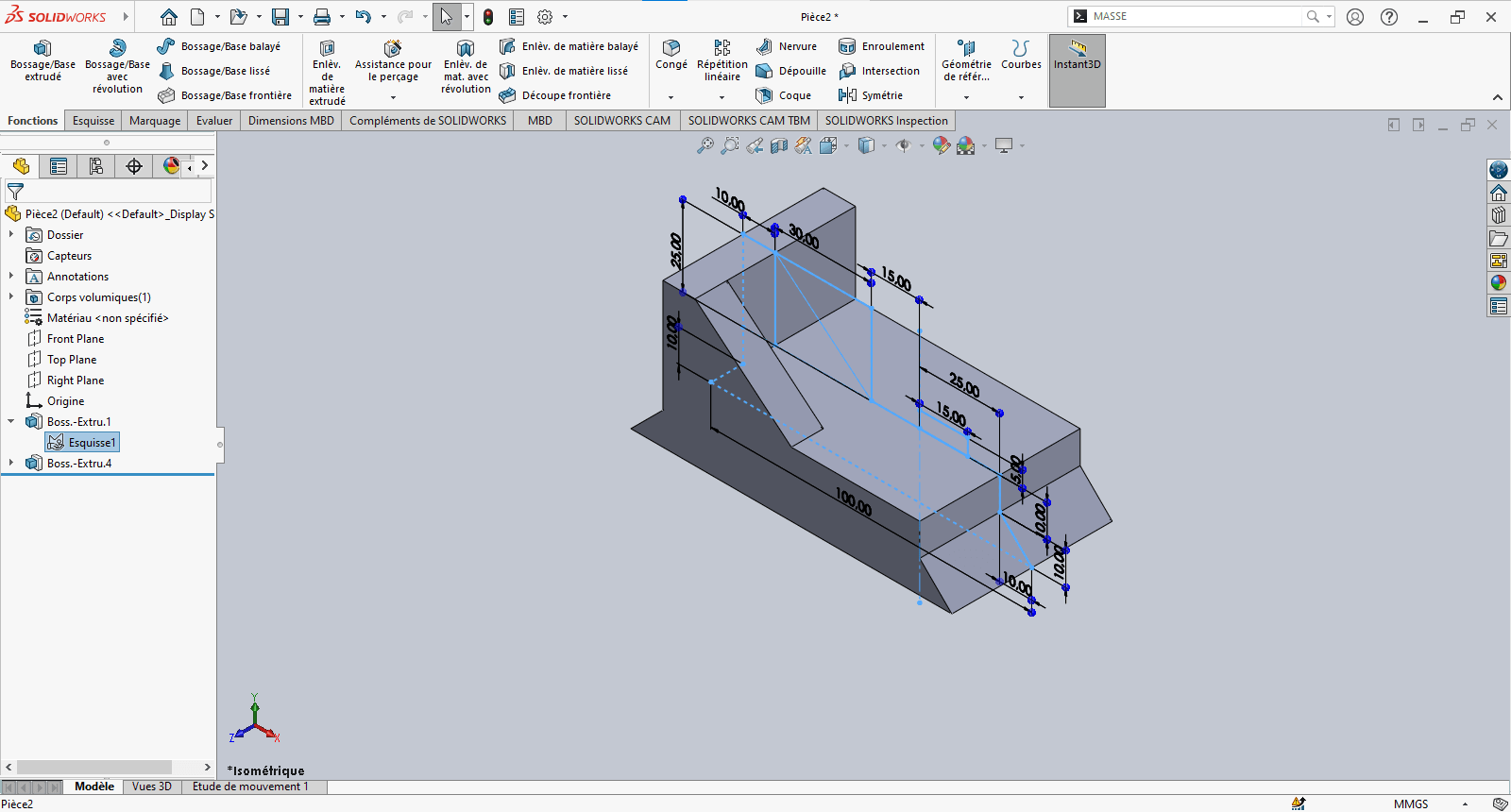

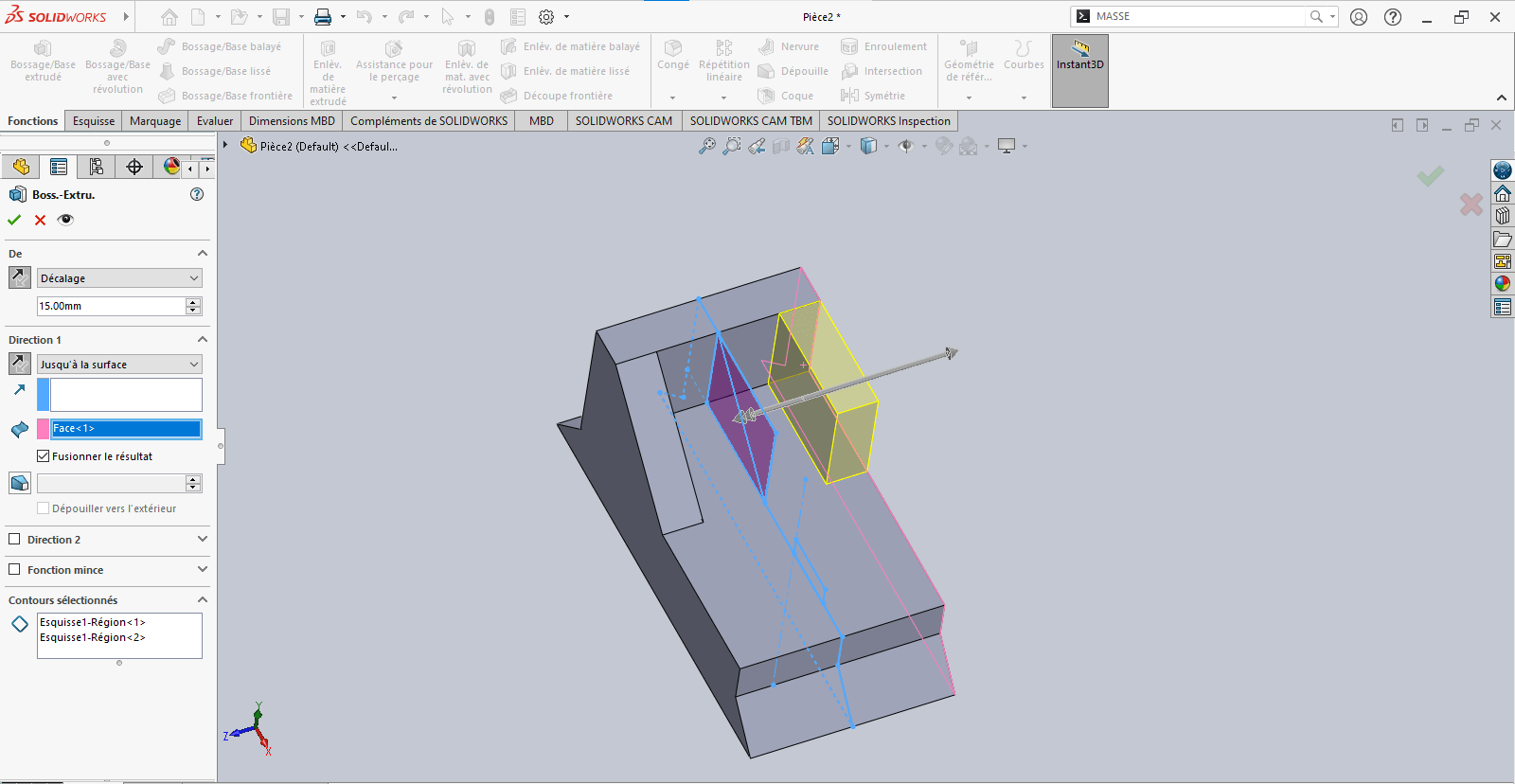

---> Third Extrusion

-

Repeat the previous step

- Again, pay attention to offset direction

- Use Up to Surface for precise alignment

-

Confirm the operation

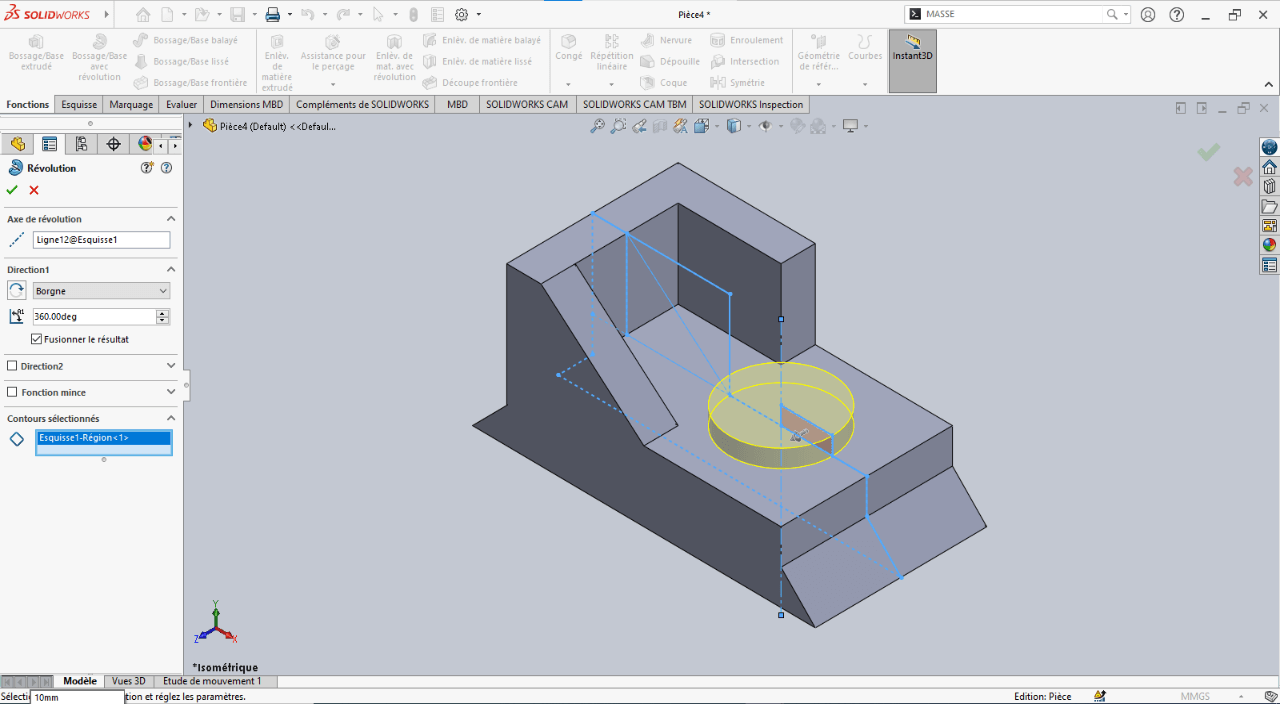

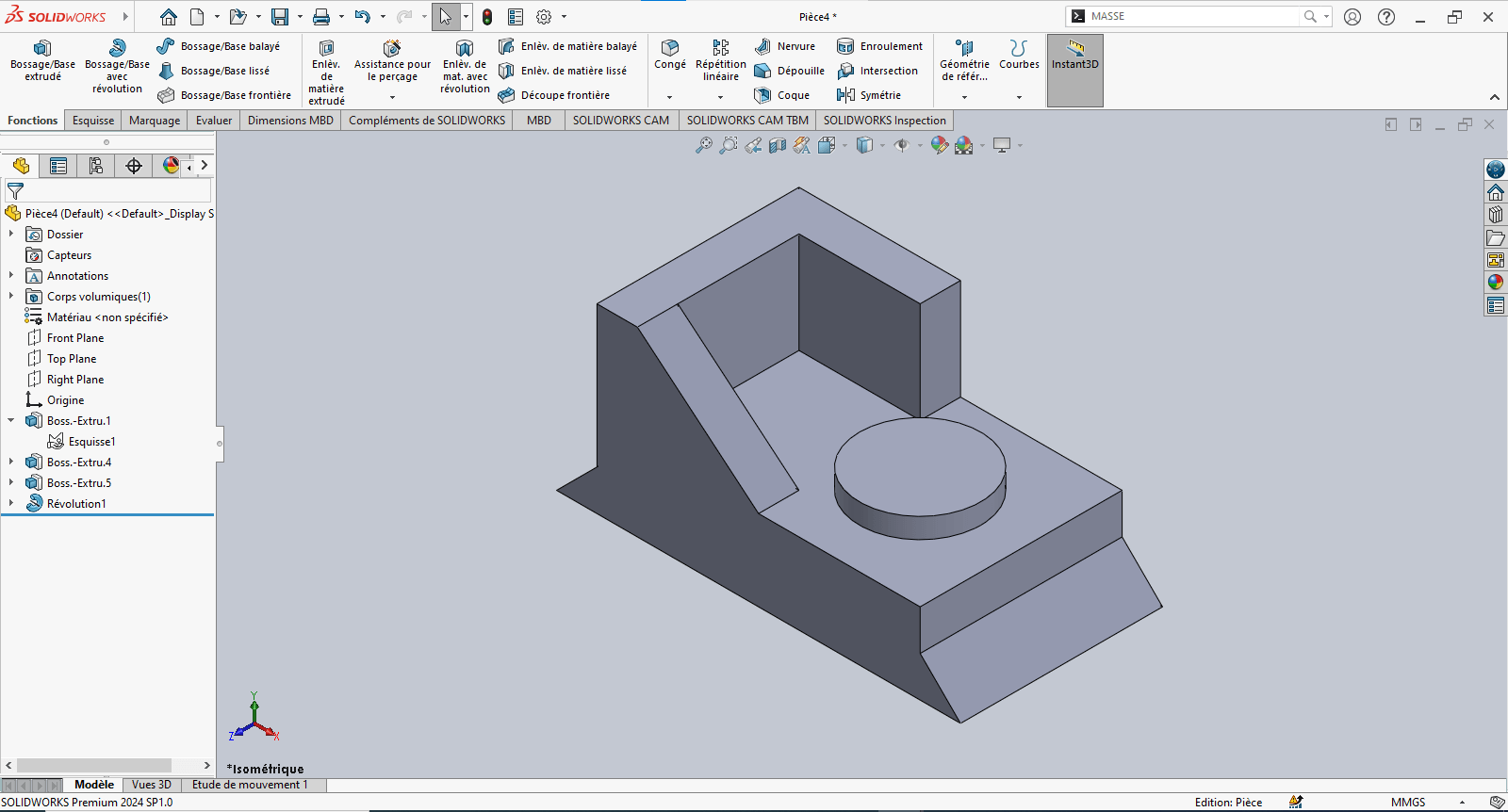

--> 5. Revolved Feature

-

In the sketch, select Revolved Boss/Base

- Specify the revolution angle

- Select the profile to revolve

- Choose the axis of revolution

-

Confirm the feature

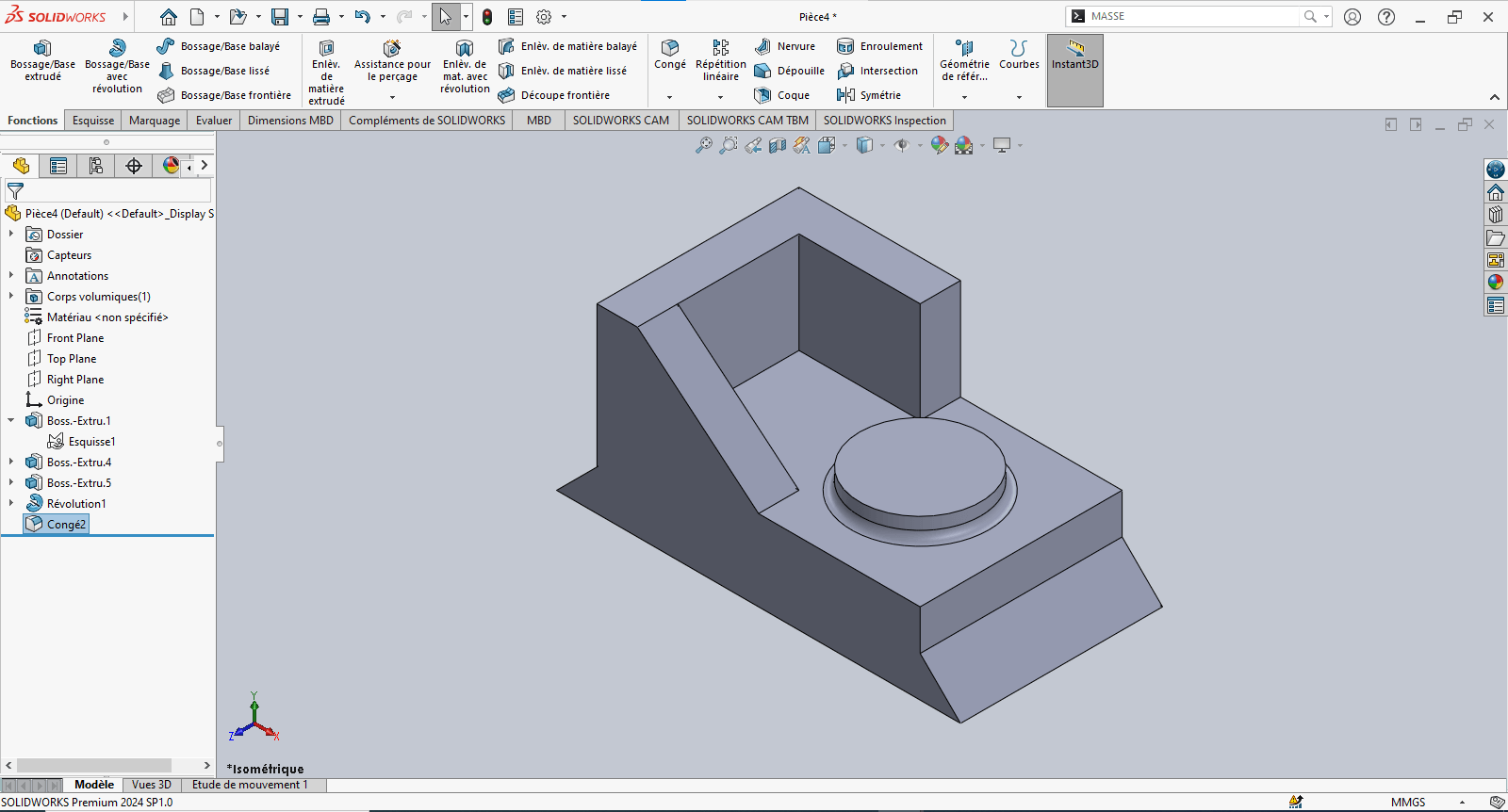

--> 6. Adding Fillets

- Use the Fillet tool to apply a 2 mm radius to the designated edge(s)

- Validate the fillet

--> 7. Evaluating the Part's Mass

- Type "Mass" in the search bar

- Click on Mass Properties

- Review the calculated mass value

The piece mass is : 112.37 gramms

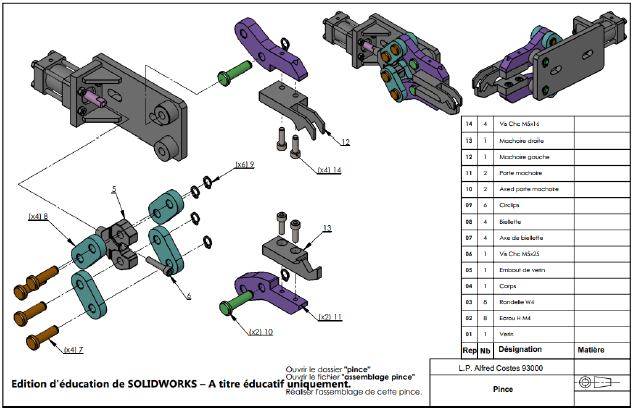

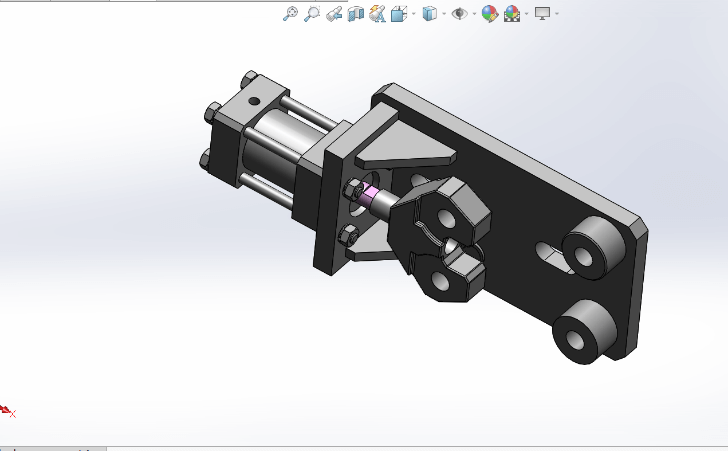

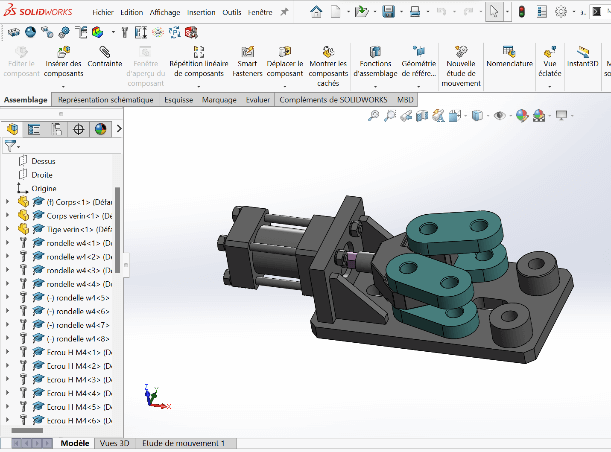

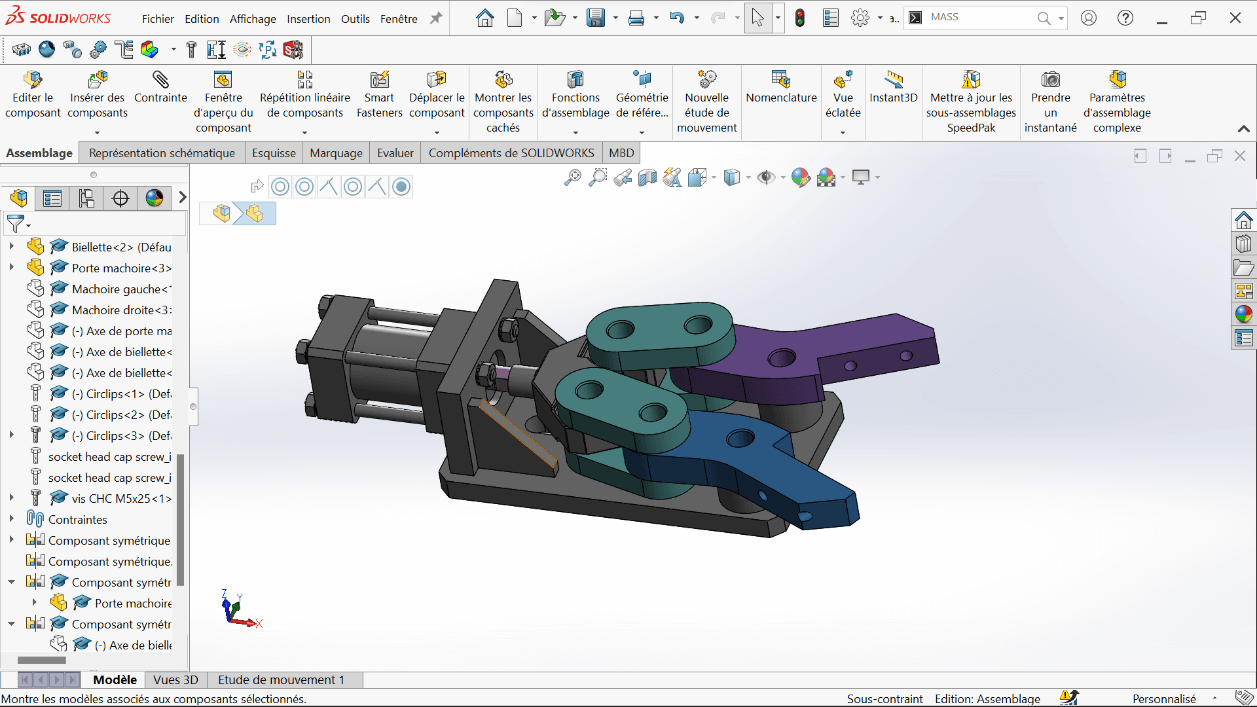

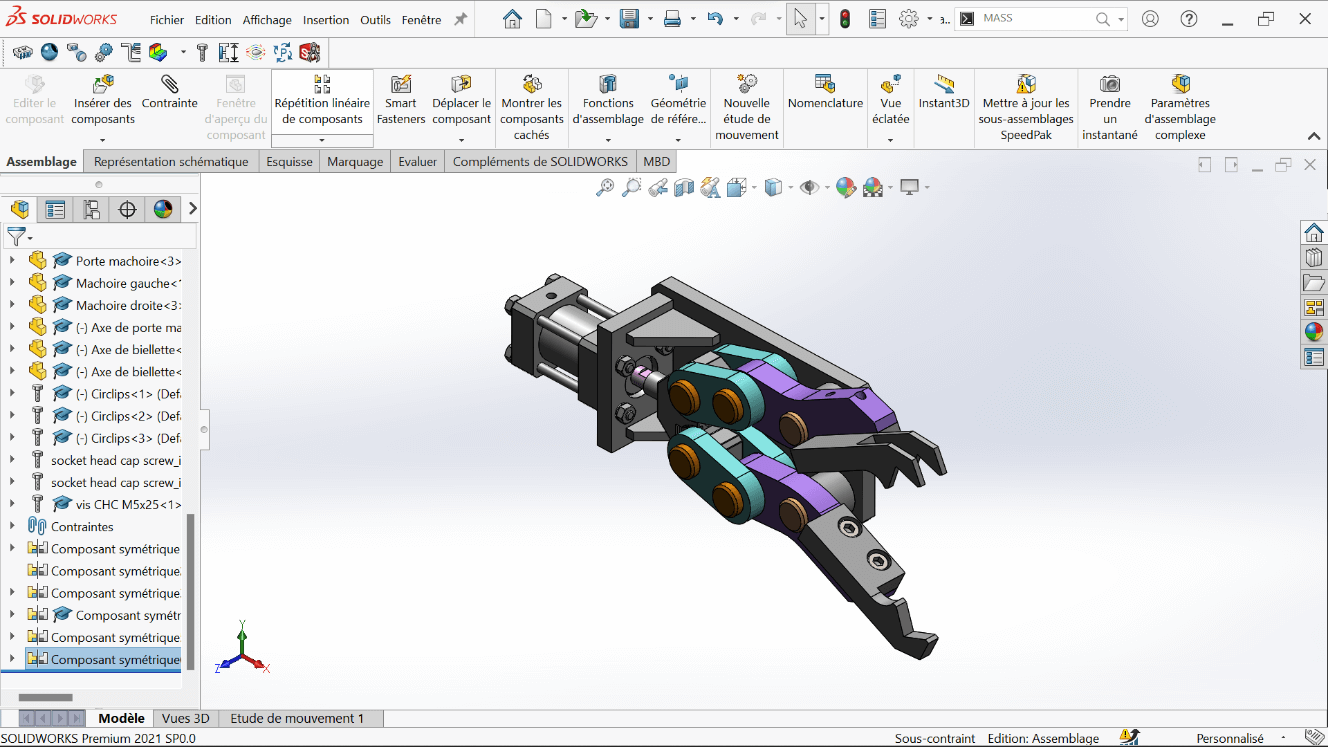

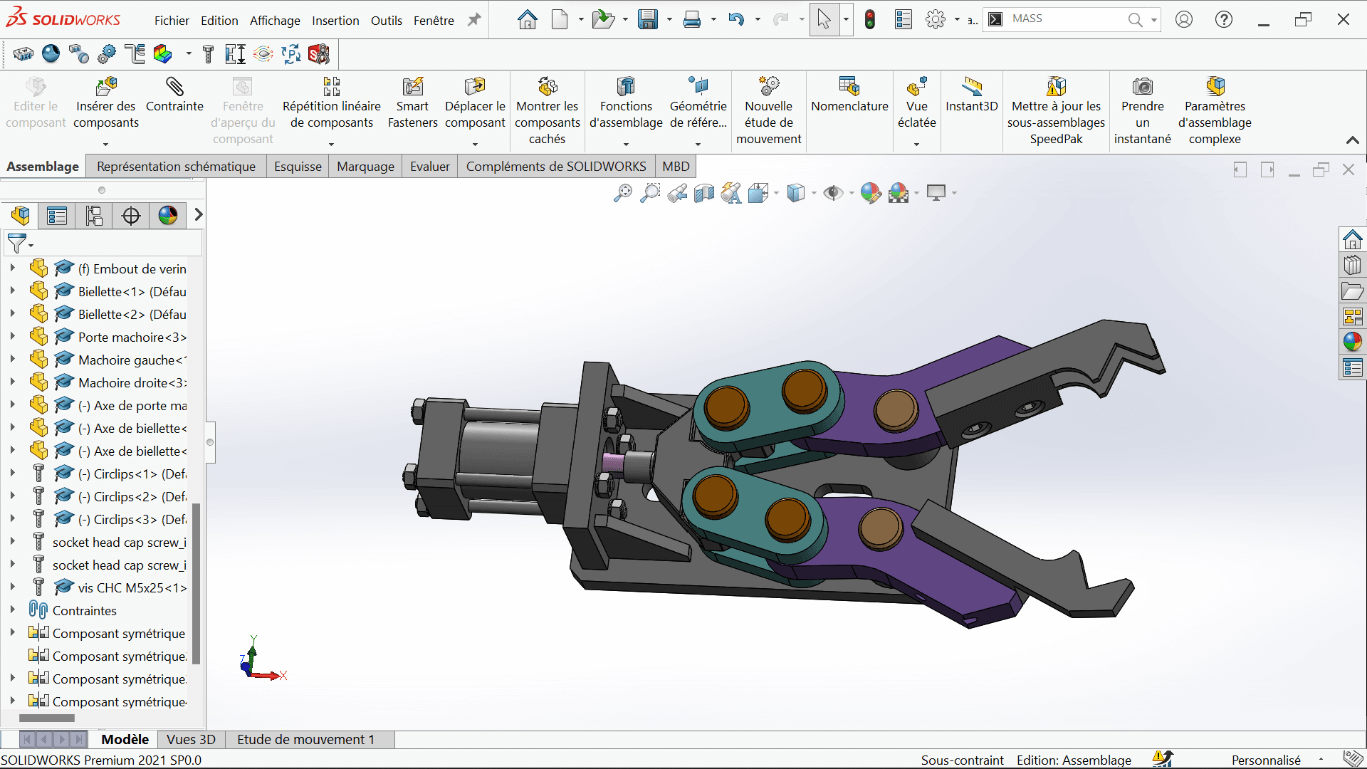

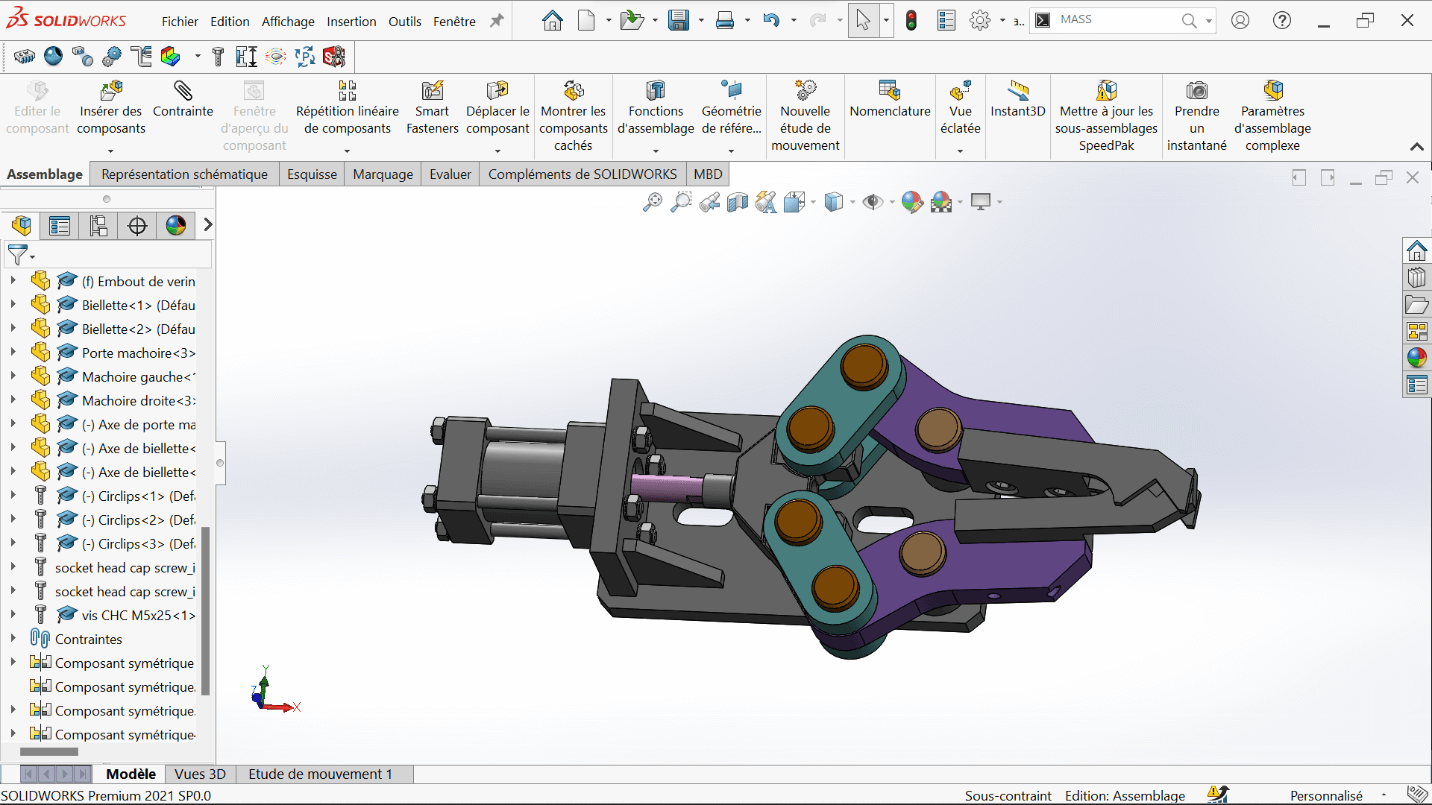

Assembly – Mechanical Gripper

Objective

This stage of the test involves assembling various components to form a mechanical gripper. After downloading the provided .zip file, the goal is to assemble the given parts using appropriate constraints.

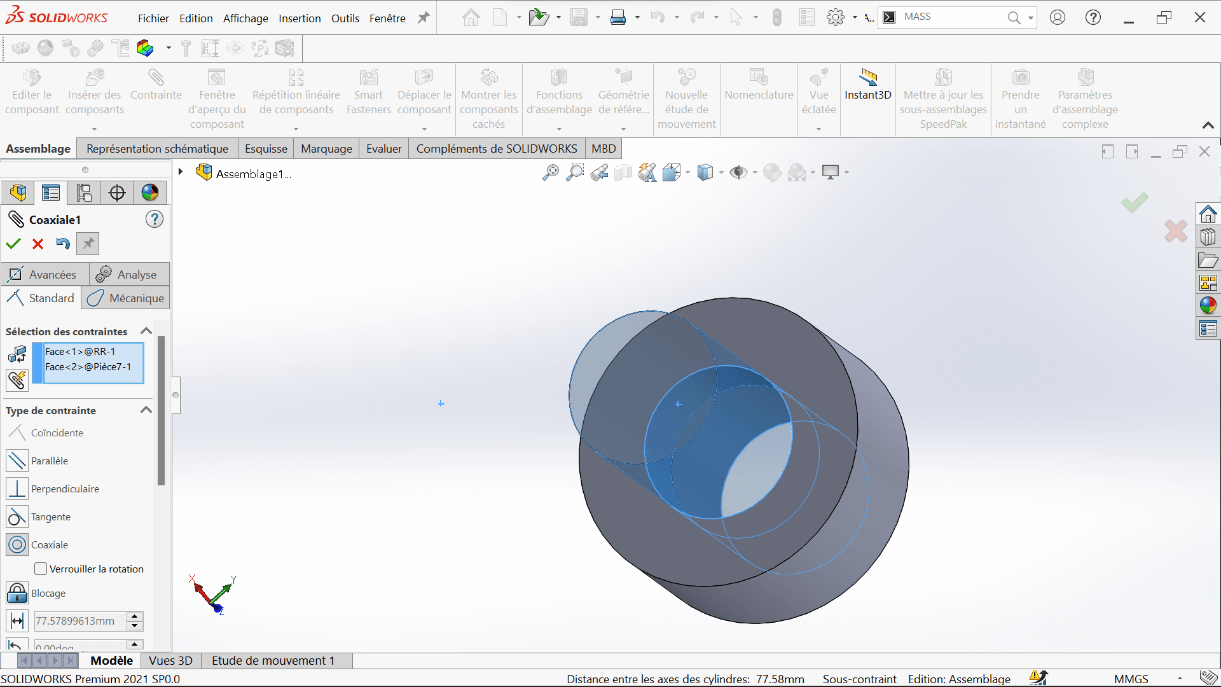

Constraints and Functions Used in the Gripper Assembly

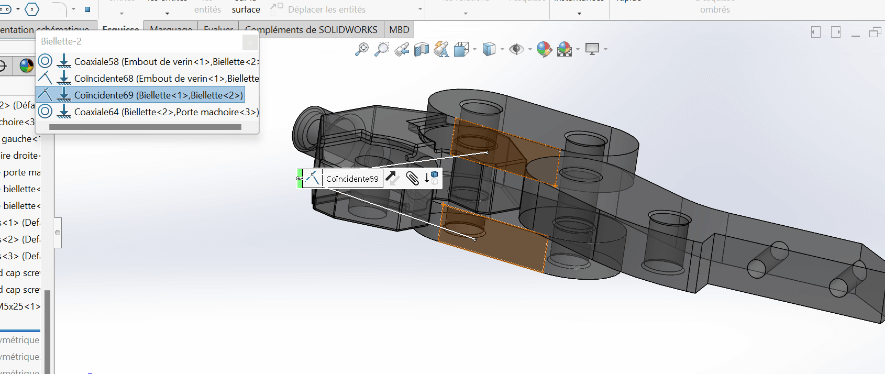

--> 1. Coaxial Constraint

This constraint aligns two cylindrical or circular axes (holes, shafts, cylinders) to share the same center axis.

Example: Aligning a shaft with its corresponding hole ensures proper axial alignment.

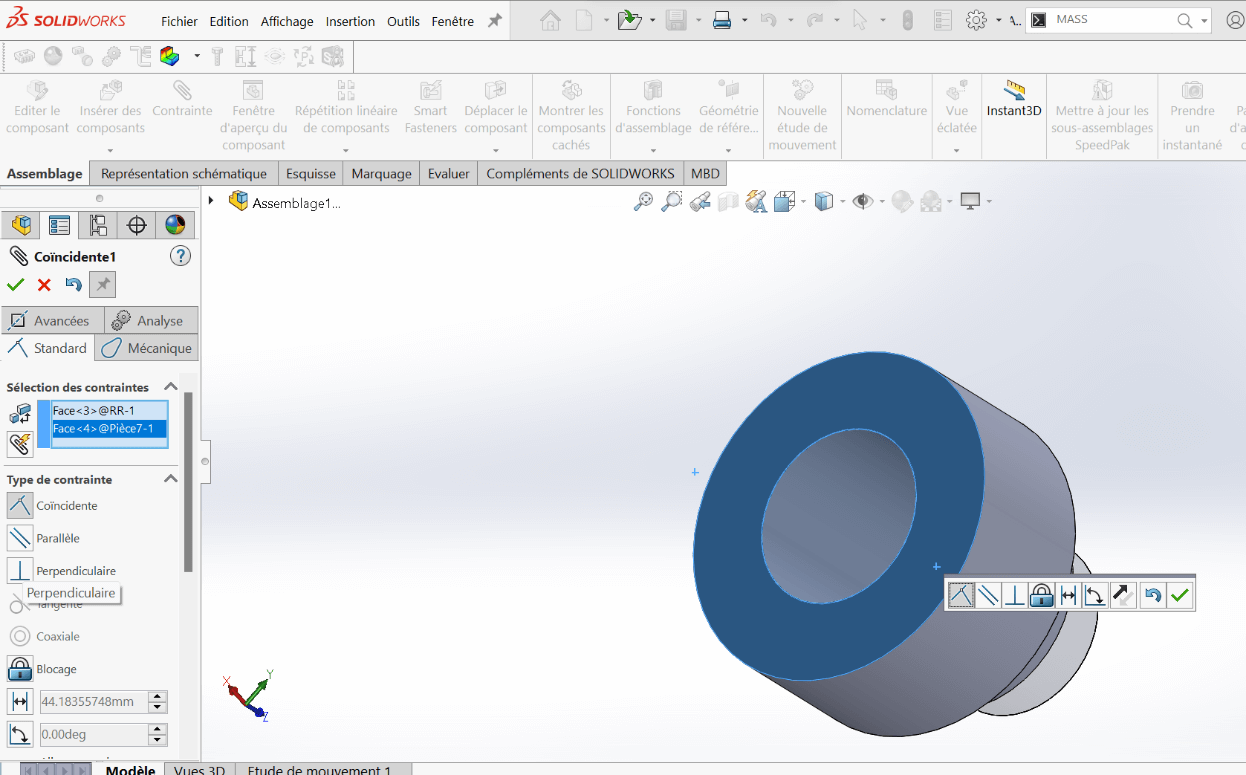

--> 2. Coincident Constraint

This constraint forces two planar or linear surfaces to touch, making them coplanar or flush.

Usage: Used to attach one part directly against another.

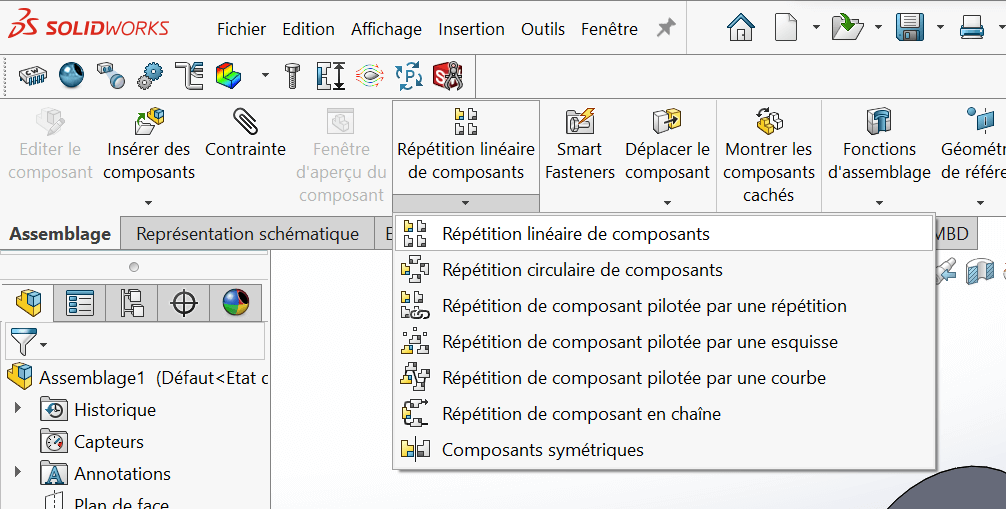

--> 3. Symmetric Components Function Under the Linear Component Pattern feature, this function generates a mirrored component from a parent part across a defined reference plane.

Assembly Steps

- Open SolidWorks, then open the file

ASSEMBLAGE PINCE.

- Insert the following parts to complete the mechanical gripper:

- Connecting Links (Biellettes)

- Jaw Holders (Porte Mâchoire)

- Left and Right Jaws (Mâchoire Gauche & Droite)

- Link Axles (Axe de Biellette)

- Jaw Holder Axles (Axe Porte Mâchoire)

- M5×16 Screws

- M5×25 Screws

- Circlips

Positioning the First Link

- Insert the first biellette (link)

- Apply Coaxial and Coincident constraints to mount it on top of the cylinder rod end

Adding the Second Link

- Insert the second biellette underneath the first one, with the rod end in between

- Use Coaxial and Coincident constraints for alignment

- Add a Coincident constraint between the two link faces for perfect overlap

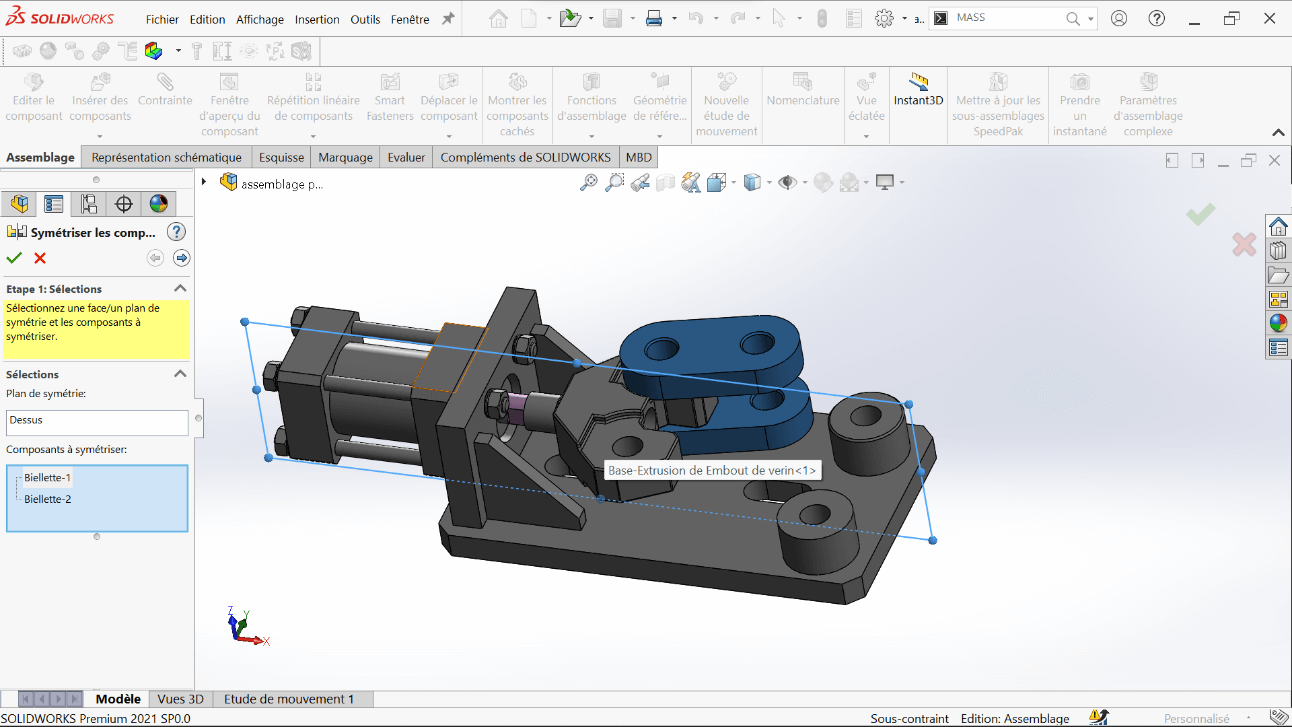

Creating Symmetry

- Use the Top Plane and the Symmetric Components tool to mirror and complete all four links required for the gripper

Adding the Jaw Holders

- Insert the Jaw Holder using Coaxial and Coincident constraints

- Apply symmetry with respect to the Top Plane, as done previously

Finalizing Assembly

- Insert the jaws (left and right)

- Add all fasteners and fixings:

- M5×16 screws

- M5×25 screws

- Link and jaw axles

- Circlips for locking

- This results in the complete mechanical gripper

Complementary Tasks

--> 1. Center of Gravity – Open Position

- Fix the rod end at the minimum extension

- Analyze the center of gravity of the entire assembly in this fully open position

| Configuration | X (mm) | Y (mm) | Z (mm) |

|---|---|---|---|

| Fully Open | -29.15 | 0.16 | 19.86 |

--> 2. Center of Gravity – Closed Position

- Fix the rod end at the maximum extension

- Analyze the center of gravity in this fully closed configuration

| Configuration | X (mm) | Y (mm) | Z (mm) |

|---|---|---|---|

| Fully Closed | -25.78 | 0.06 | 19.86 |

Errors Encountered

Problem

During the installation of SolidWorks, I encountered an issue that initially prevented successful setup.

Solution

The problem was resolved after watching a step-by-step tutorial video that clearly demonstrated the correct installation procedure and highlighted settings we had previously overlooked.

Perspectives

-

Part Optimization: Future versions of the mechanical components could explore new materials or lightweight geometries to reduce mass and improve energy efficiency.

-

Smarter Gripping Mechanisms: Integration of force sensors, soft grippers, or motor feedback could make the gripper more adaptive to different object shapes and textures.

-

System Integration: The validated modules can be scaled into more complex robotic systems, such as mobile manipulators or industrial automation platforms.

-

Simulation Before Prototyping: Leveraging SolidWorks Motion Studies, MATLAB/Simulink, or ROS-based environments for dynamic testing and control strategy validation before fabrication.

Resources

Installation Guides

-

Official SolidWorks Installation Guide (EN)

Detailed instructions to install SolidWorks on a single computer. -

SolidWorks Admin & Deployment Guides

For advanced installations, network licenses, and administrative deployments. -

SolidWorks Downloads Portal

Access to installation files, service packs, and updates (login required).

Official Tutorials & Manuals

-

Student’s Guide to Learning SolidWorks (PDF)

A comprehensive beginner workbook with hands-on exercises. -

MySolidWorks – Online Training Hub

Interactive tutorials, certification prep, and beginner-to-advanced courses.

Beginner-Friendly Video Tutorials

-

SolidWorks Tutorial for Beginners #1 – CAD CAM Tutorials (YouTube)

Start modeling with sketches, constraints, and extrusion. -

SolidWorks 2020 Full Beginner Tutorial – Aryan Fallahi (YouTube)

A concise intro to interface, part design, and assemblies. -

SolidWorks Tutorials for Beginners (Website)

Detailed walkthroughs on tools, menus, and modeling strategies.

Additional Resources

-

Last Minute Engineers – CAD & Arduino Projects

Perfect for blending SolidWorks with real-world embedded projects. -

GrabCAD Library – SolidWorks Files

Thousands of free SolidWorks models and parts to download and explore. -

SolidWorks Forums (EN)

Ask questions, get help, and join discussions with the global community.