3rd Test

Objective

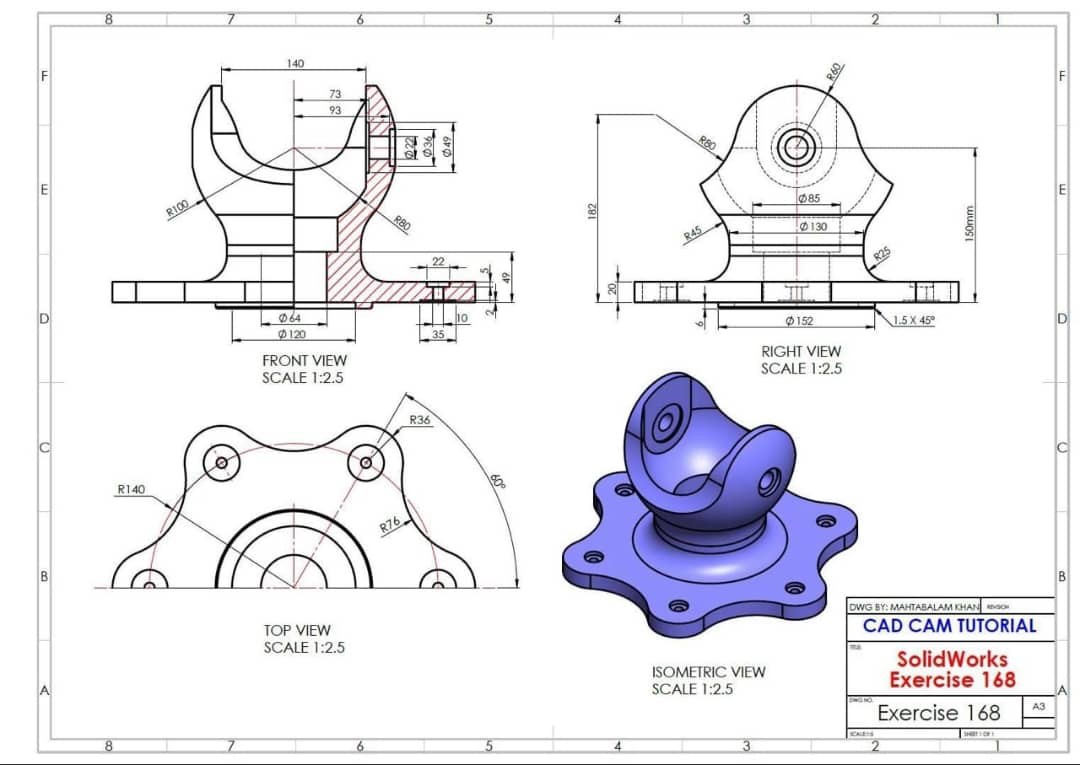

The advanced level Test 3 consists of modeling a complex part that will be validated by achieving the appropriate mass.

Material specifications:

- Material: 1060 Alloy Aluminum

- Density: 2700 Kg/m³

Summary

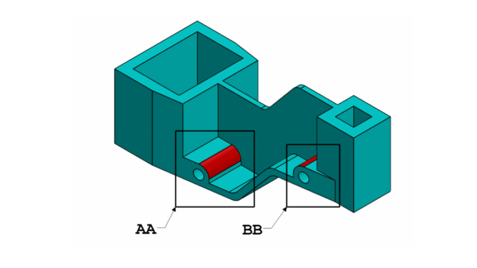

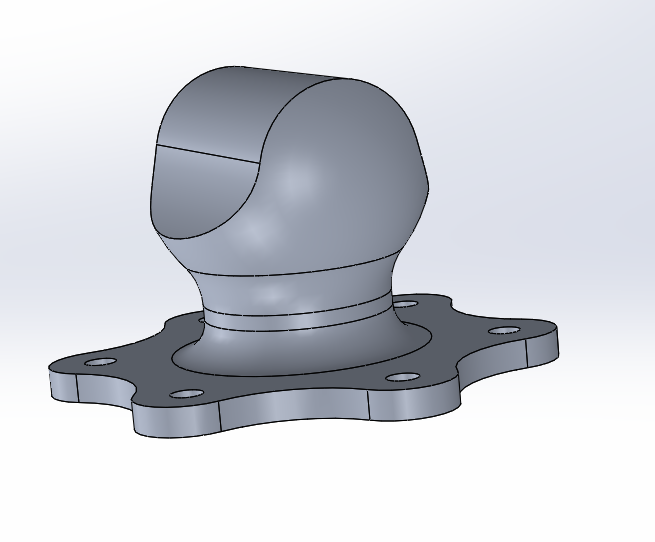

This part was mainly created using the following features:

- Extruded boss

- Extruded cut

Mass Table

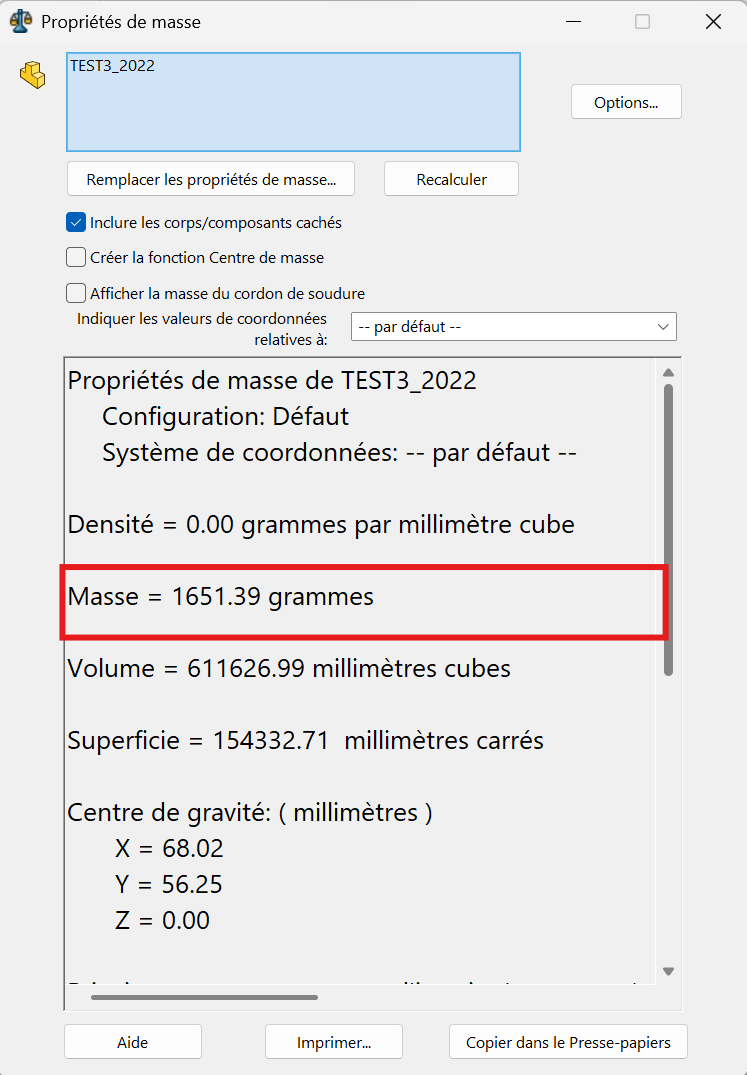

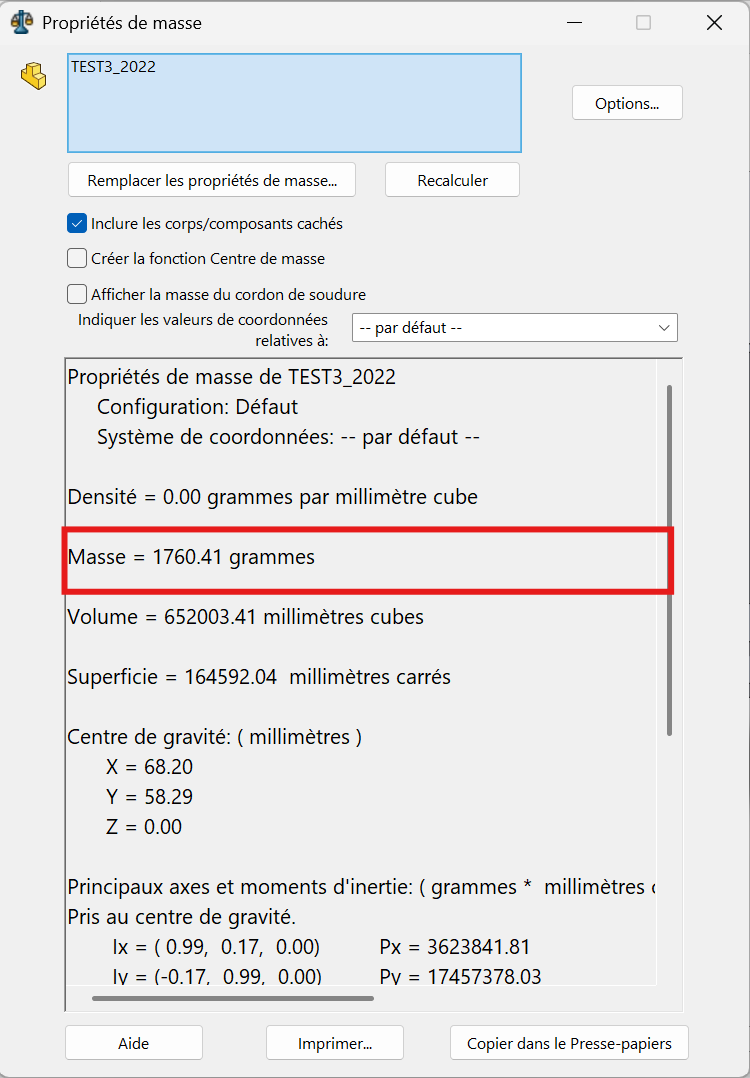

| Configuration | Mass (g) |

|---|---|

| (a) A = 193 mm; B = 88 mm; W = B/2 mm; X = A/4 mm; Y = B+5.5 mm; Z = B+15mm | 1400.64 |

| (b) A = 205 mm; B = 100mm; W = B/2 mm; X = A/4 mm; Y =B+5.5 mm; Z = B+15 mm | 1651.39 |

| (c) A = 210 mm; B = 105 mm; W = B/2 mm; X = A/4 mm; Y = B+5.5 mm; Z = B+15mm | 1760.41 |

Video

Files available for download

Download the modeling files by clicking by following these links :

-

Case 1 : SolidWorks File - case1

-

Case 2 : SolidWorks File - case2

-

Case 2 : SolidWorks File - case3

Part Creation Process

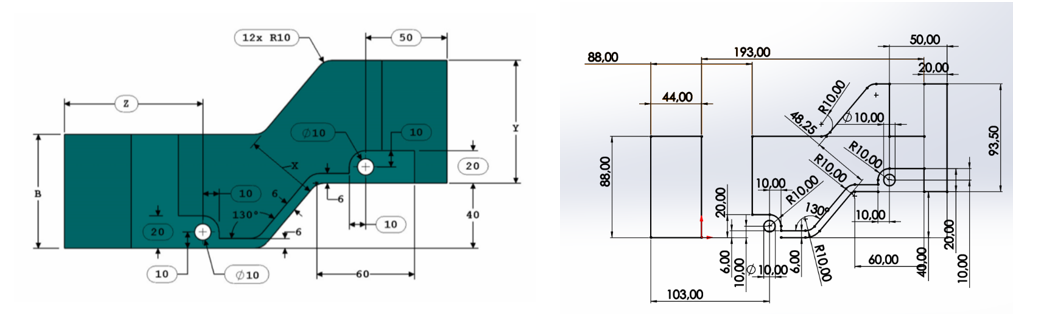

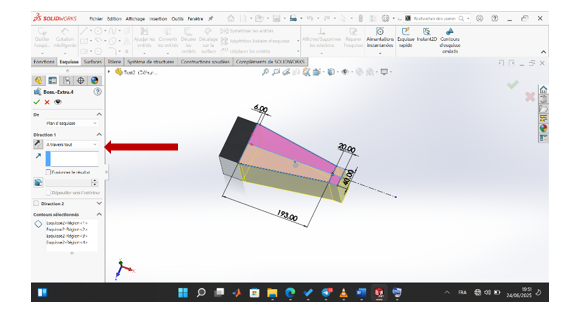

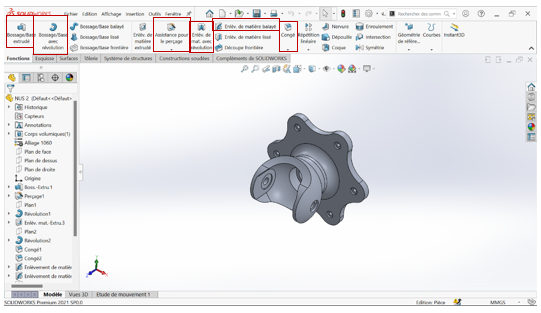

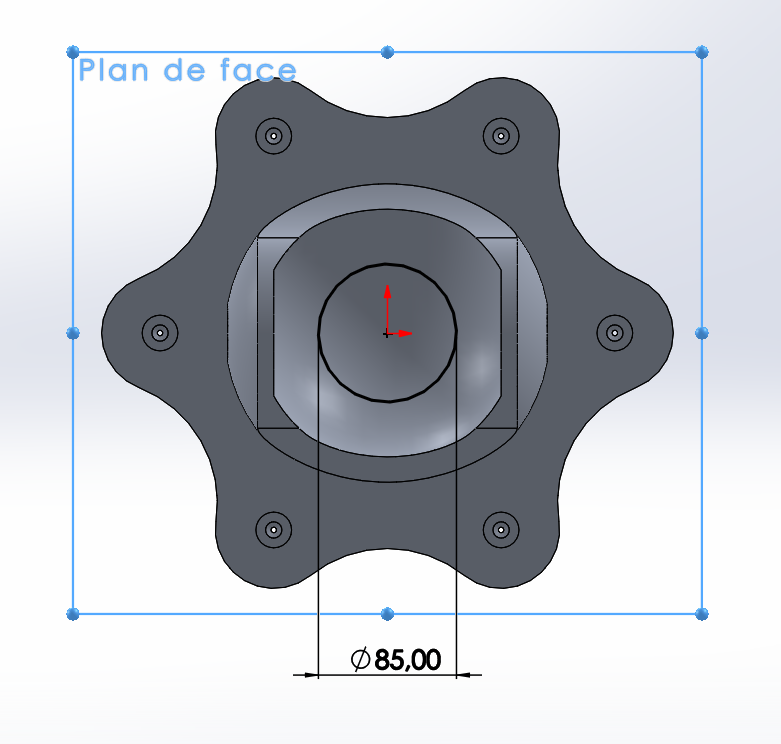

Step 1: Initial Sketch

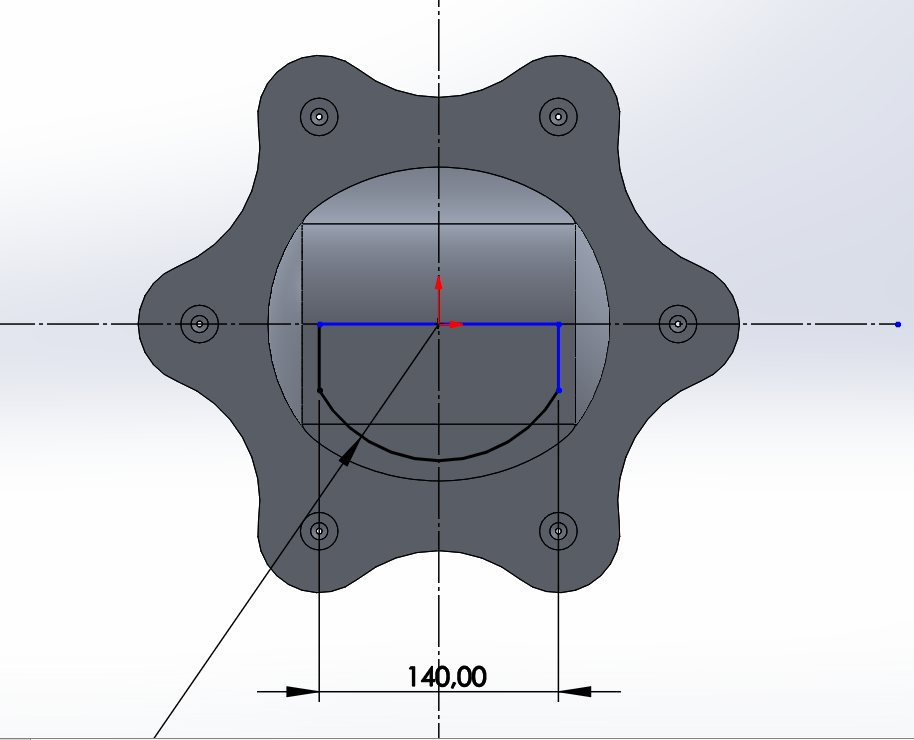

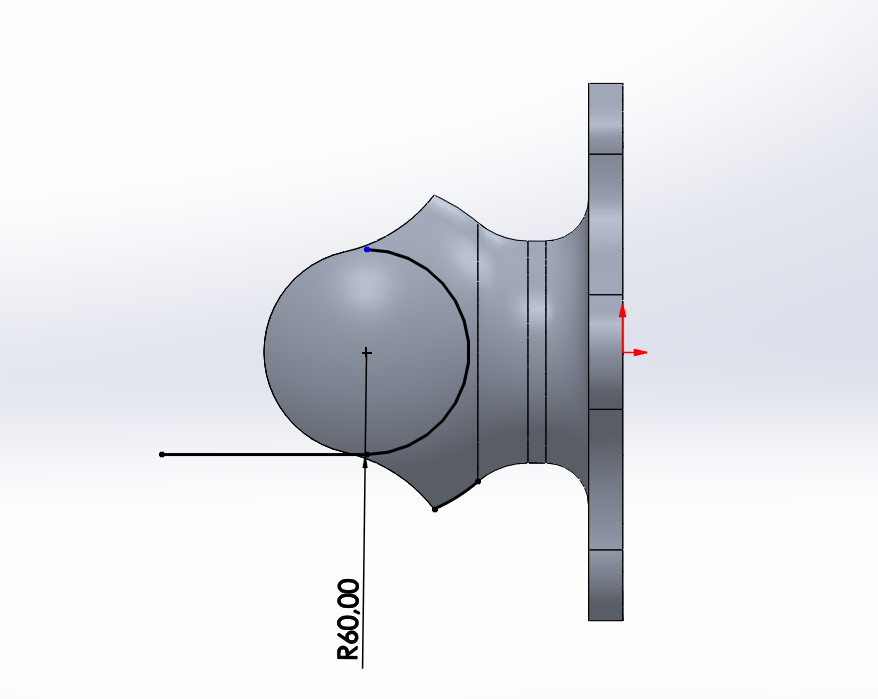

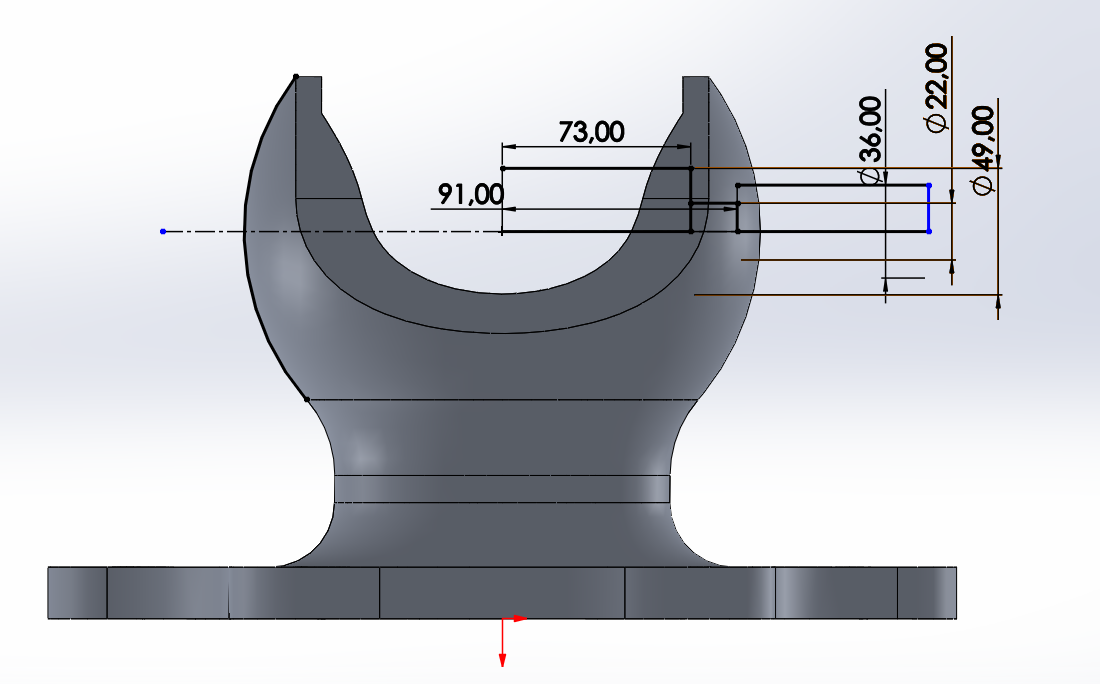

On the front plane, draw the following view while respecting the dimensions and angles.

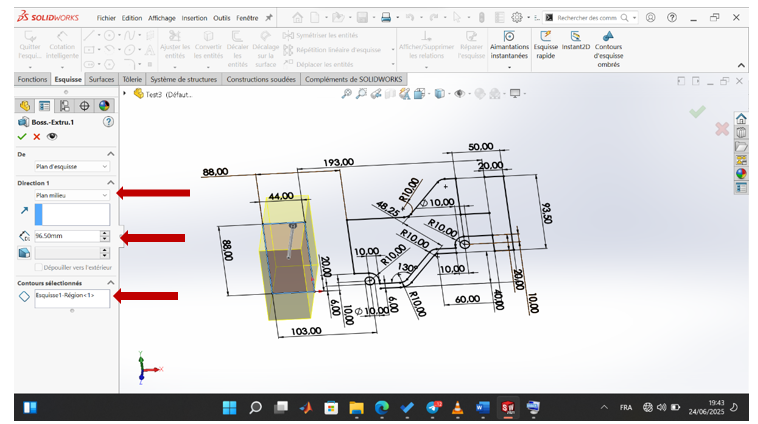

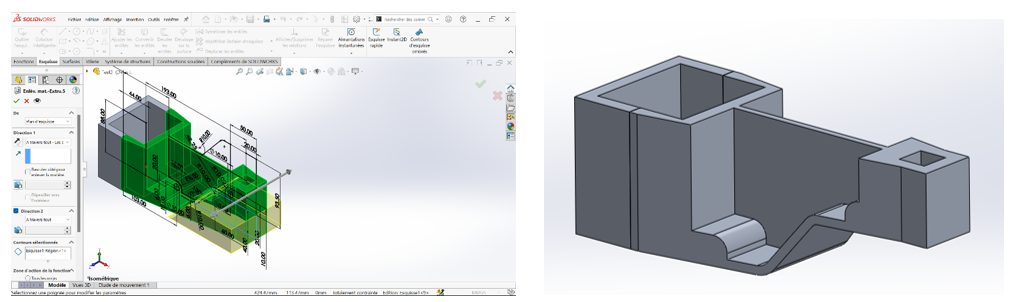

Step 2: Base Extrusion

Use the extruded boss feature and extrude the selected region by 96.5 mm using the mid-plane option.

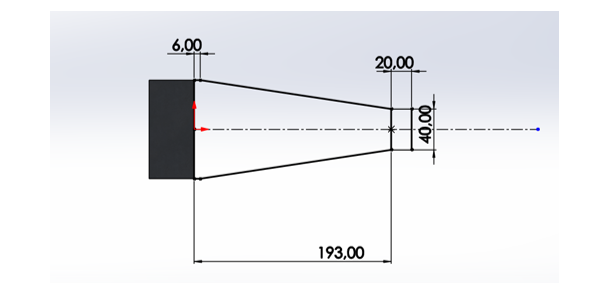

Step 3: Trapezoid Shape

On the top plane, make the following sketch with a 6 mm offset to get the trapezoid shape.

Step 4: Through Extrusion

Make a through all extruded boss.

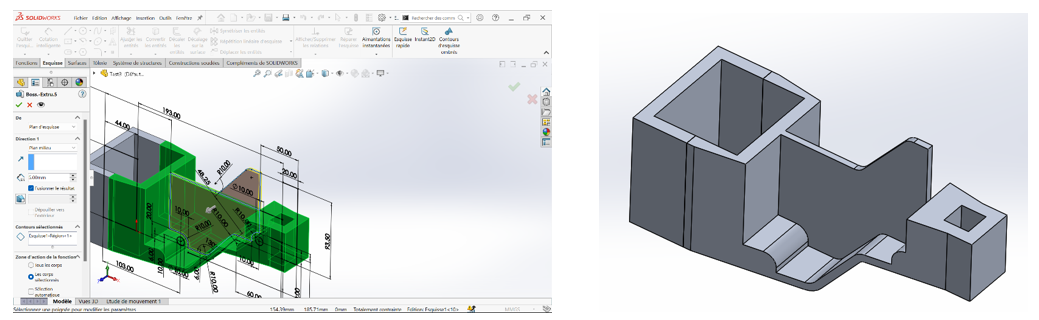

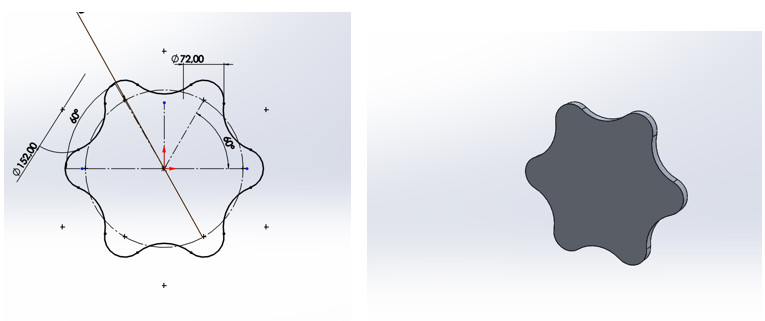

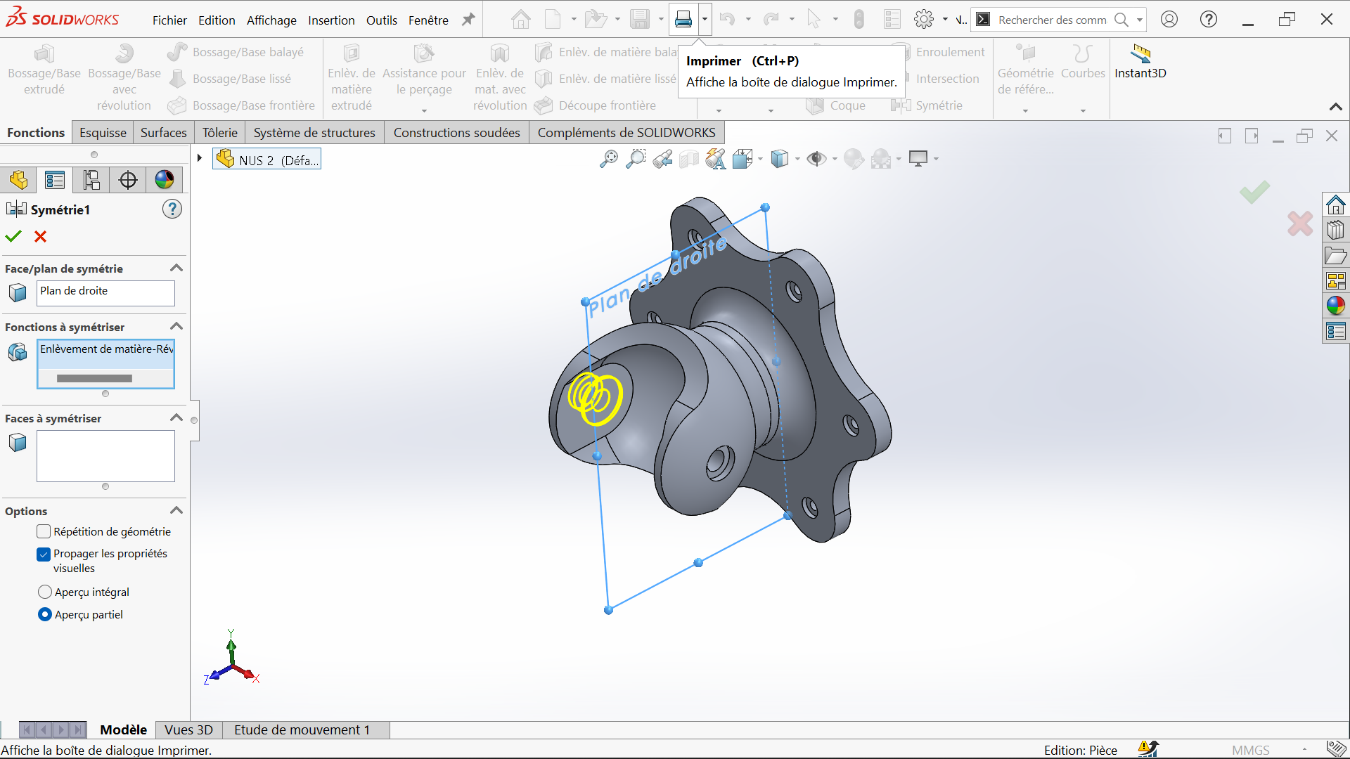

Step 5: Material Removal Series

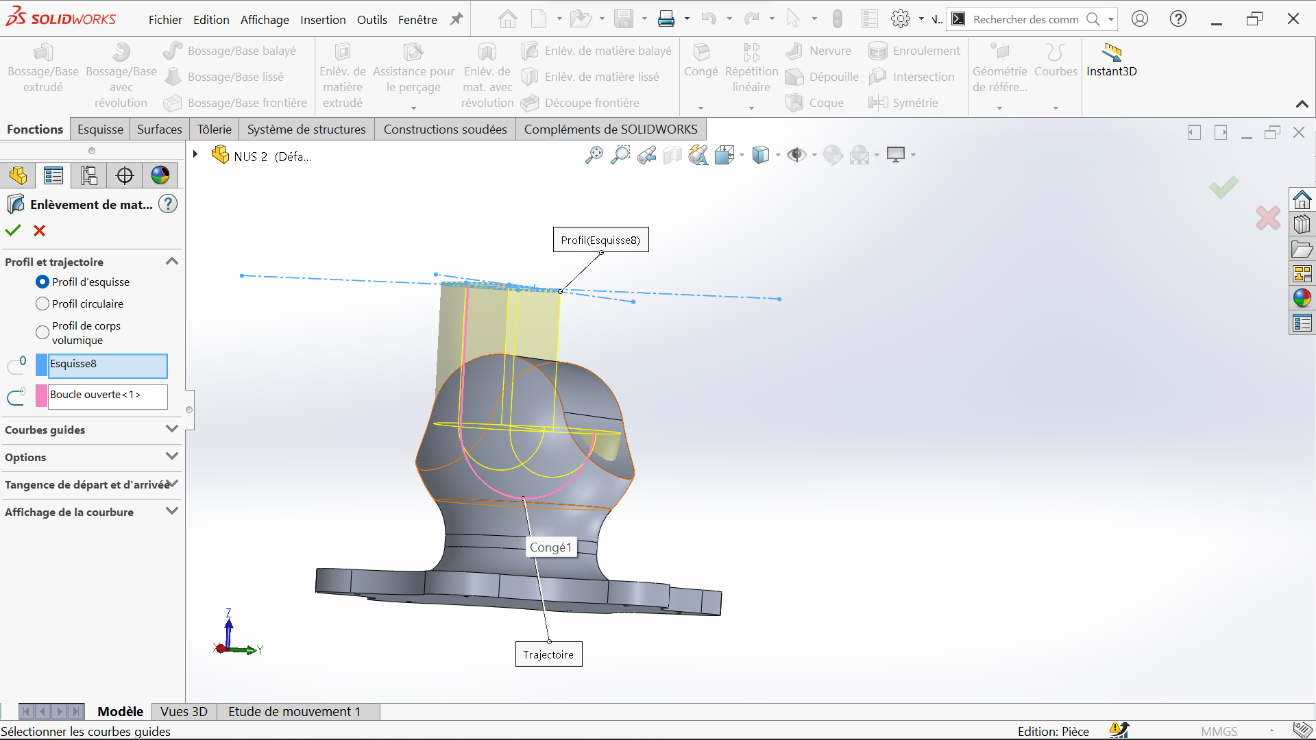

Proceed with a series of extruded cuts.

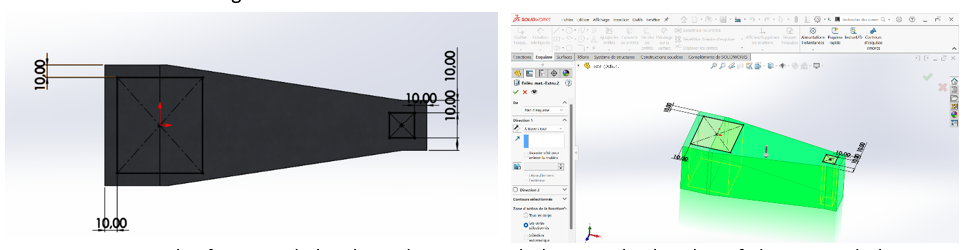

Step 6: First Cut

Make a through all extruded cut from the sketch.

Step 7: Bilateral Cuts

Using the first initial sketch, make an extruded cut on both sides of the region, leaving a 5 mm gap between them. Each cut is made with a 2.5 mm offset.

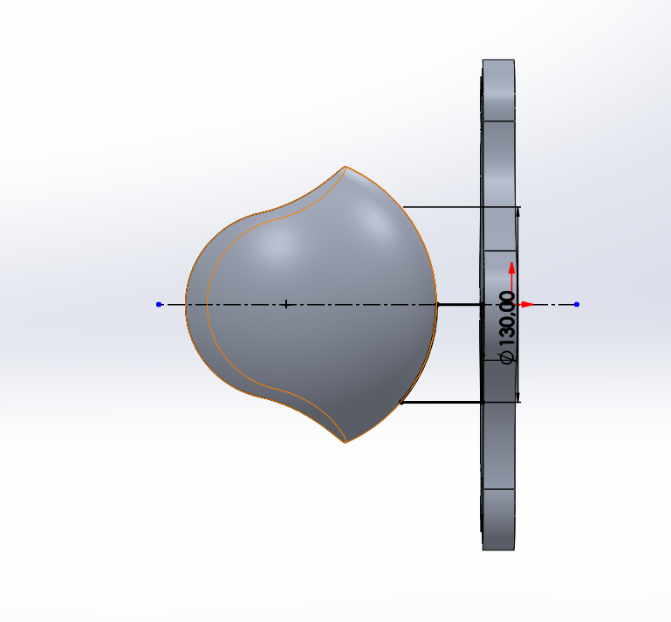

Step 8: Intermediate Result

After this operation, we obtain an intermediate part form.

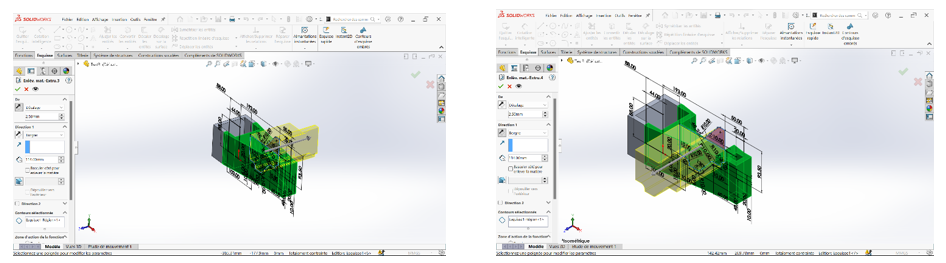

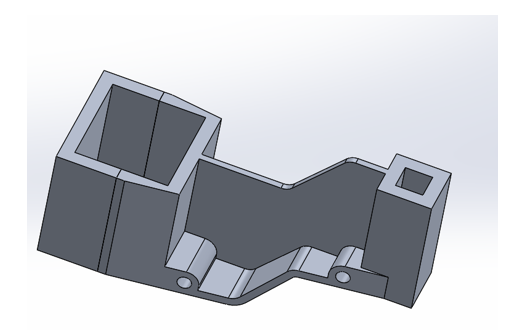

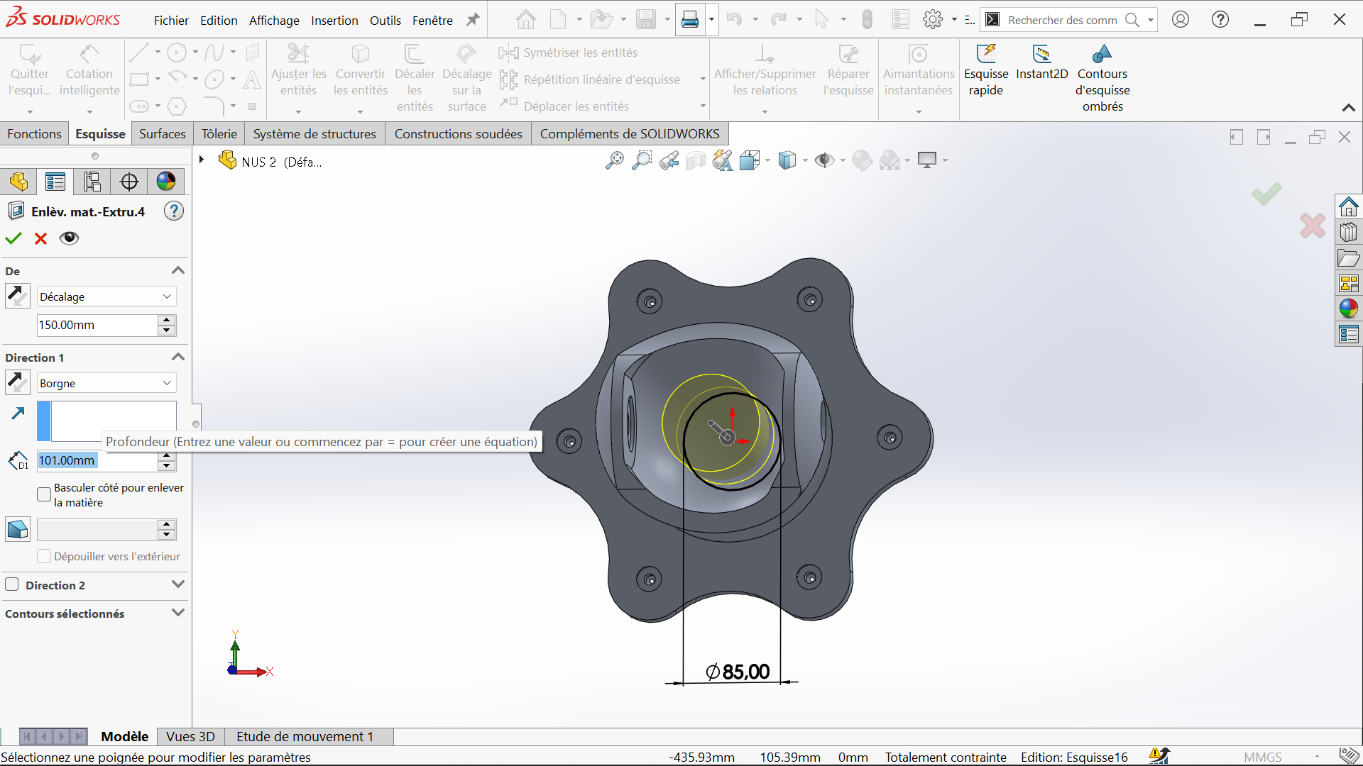

Step 9: Additional Material Removal

Continue with material removals for the region of sketch 1 (the first sketch).

Step 10: Mid-plane Boss

Still using the first sketch, create a 5 mm extruded boss with the mid-plane option.

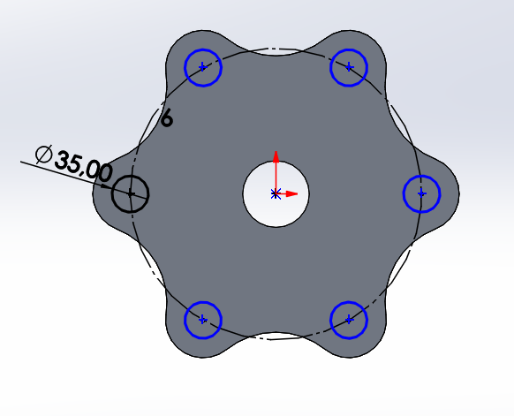

Step 11: Final Features

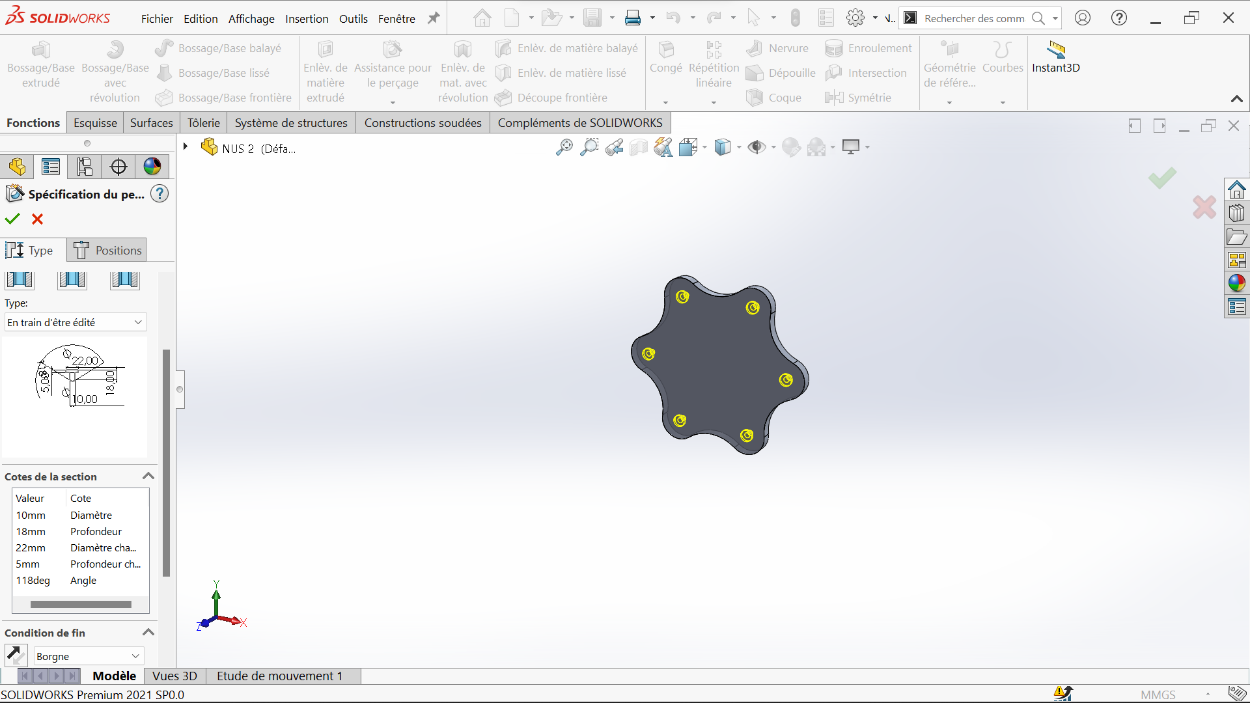

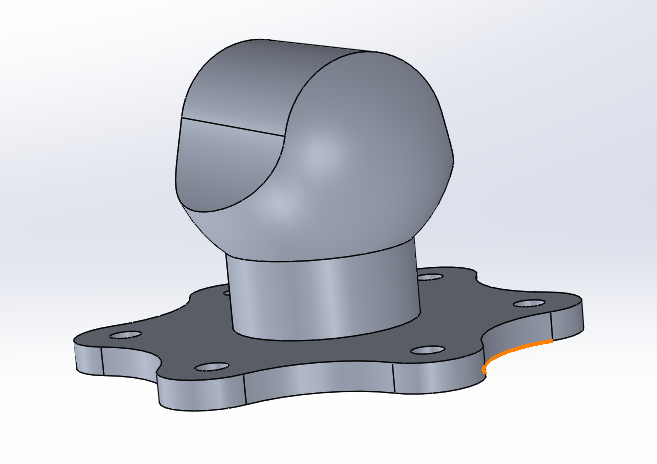

By making an extruded boss from the sketch on the top plane and extruded cuts for the 10 mm holes, we obtain the penultimate part.

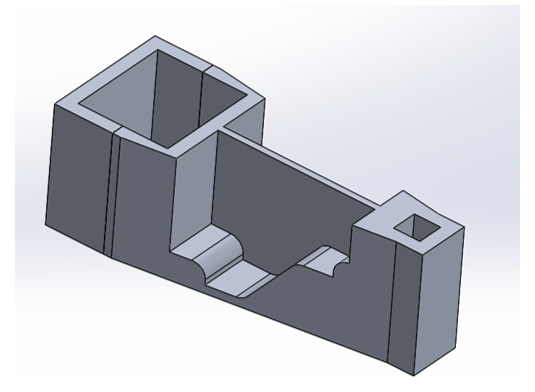

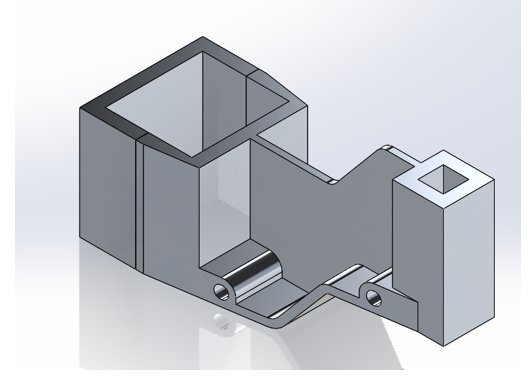

Step 12: Final Part

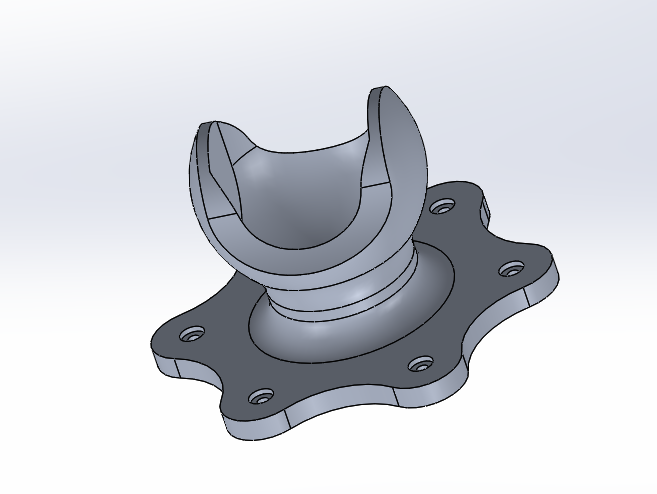

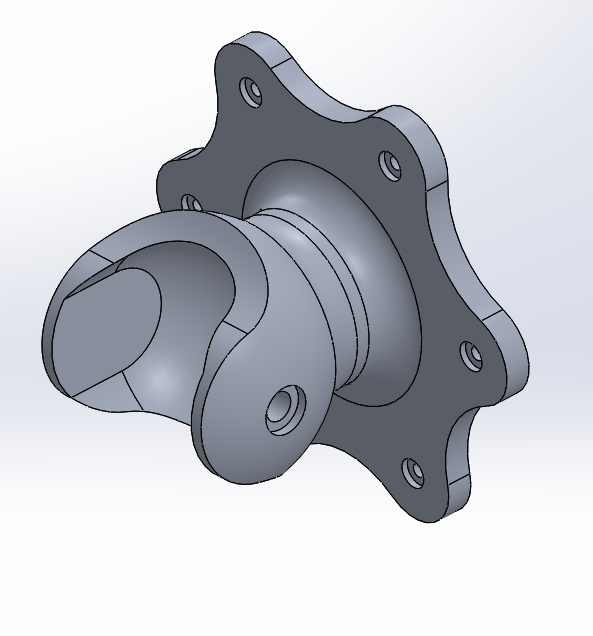

Apply the material and the desired display mode. This gives us the final Test 3 part.

Variable Dimension System

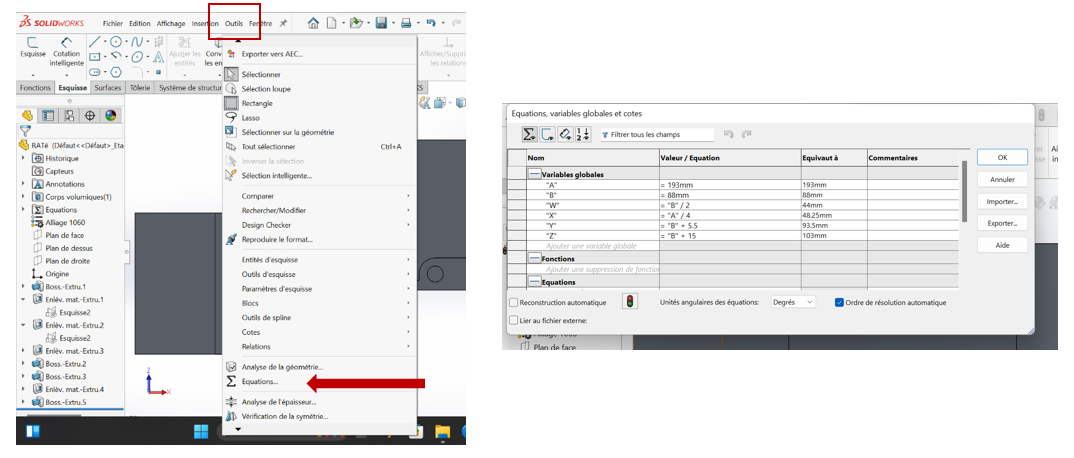

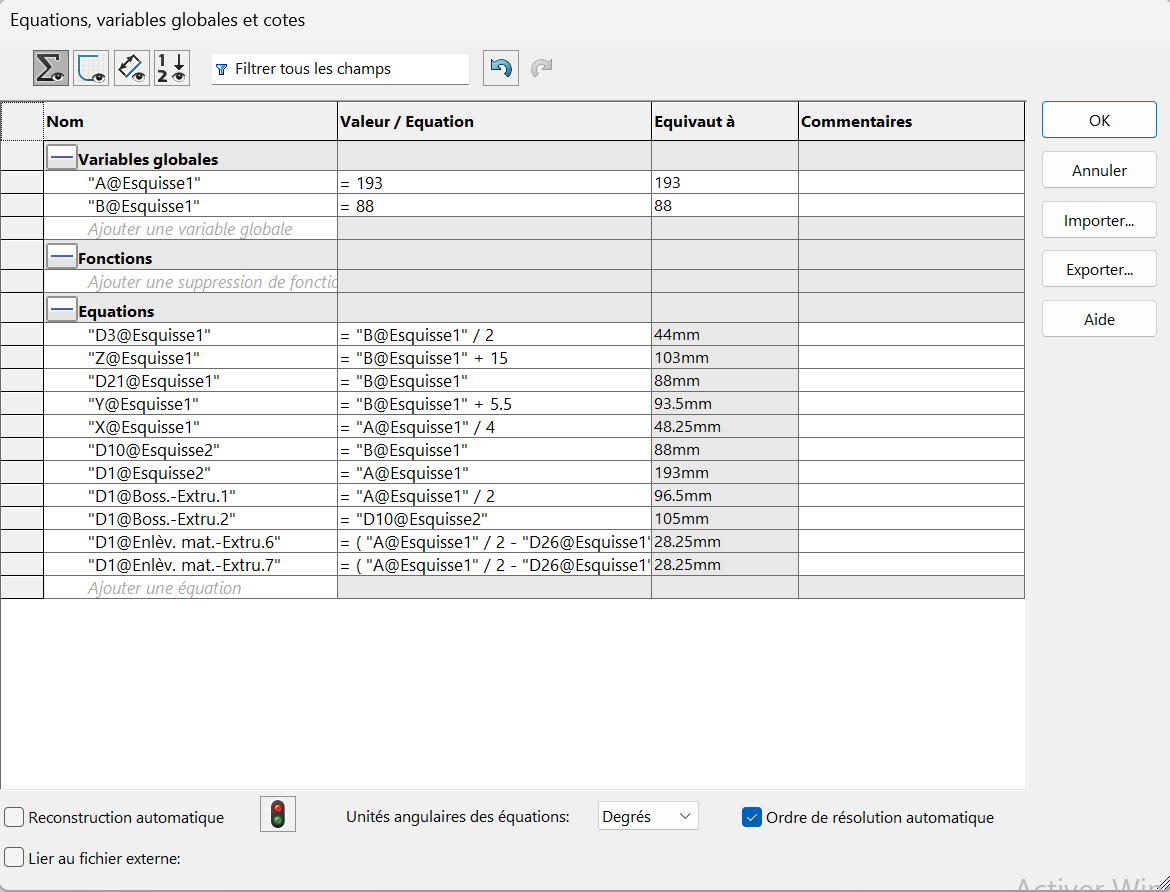

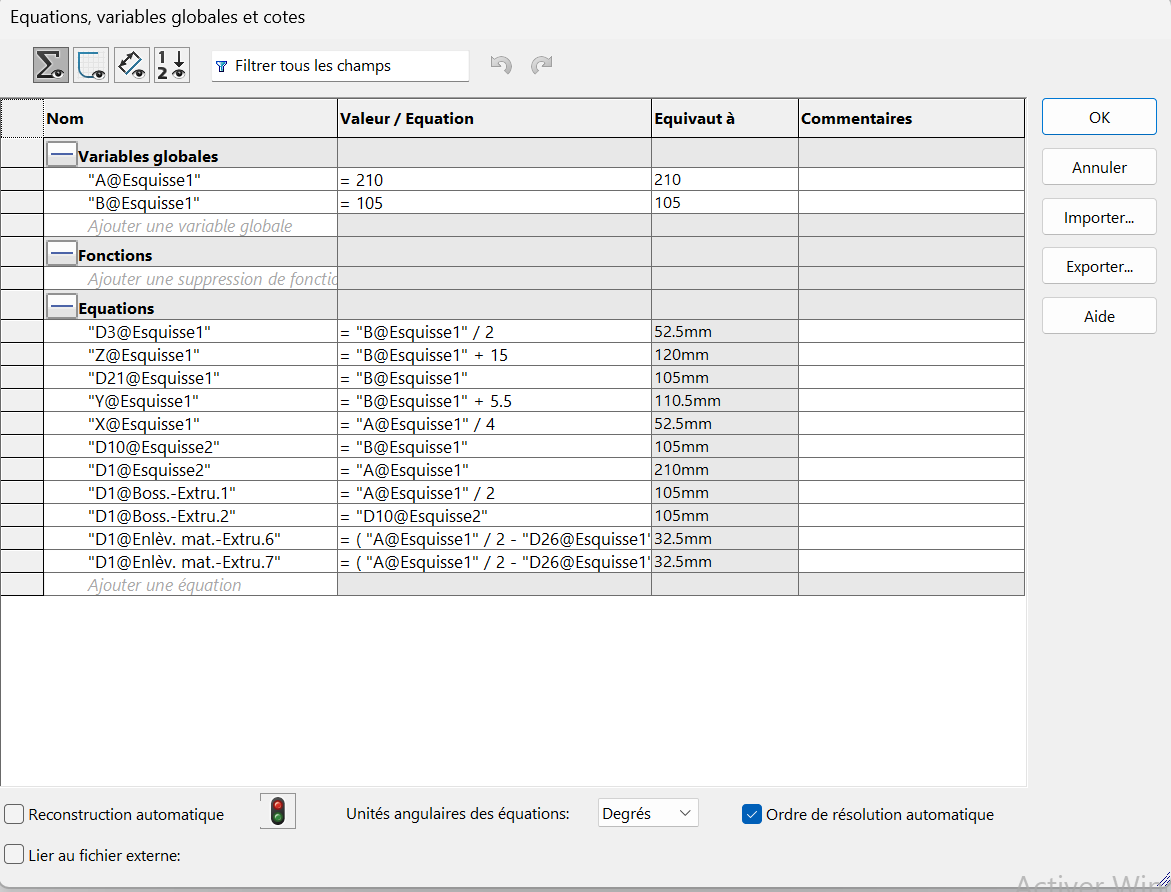

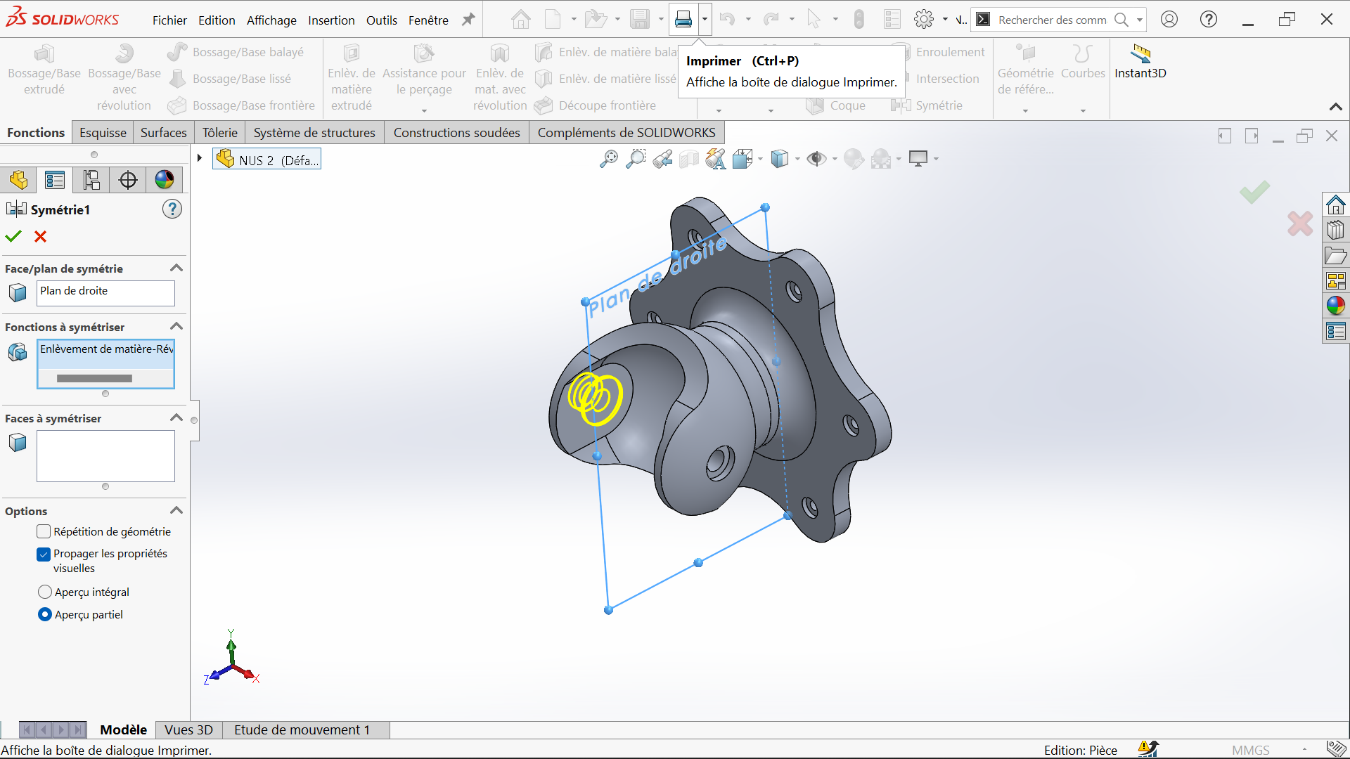

Step 13: Global Variables Setup

For this test, dimensions A, B, Z, Y, X, W must be modified to obtain a new part with a different mass each time. To achieve this:

- Use the equation tool

- Add global variables

- Each time we modify these global variables, the dimensions are adjusted automatically

- This generates a new part configuration

Step 14: Variable Linking Methods

When dimensioning to use variables:

Method 1: Use "=" which allows selection of the variable in question

Method 2: Link the dimension already placed on the drawing to the global variable already created

Step 15: Multiple Configurations

At the end of this series of variable modification operations, we obtain 3 different pieces of different masses. The masses of the pieces are designated as configurations a, b, and c.

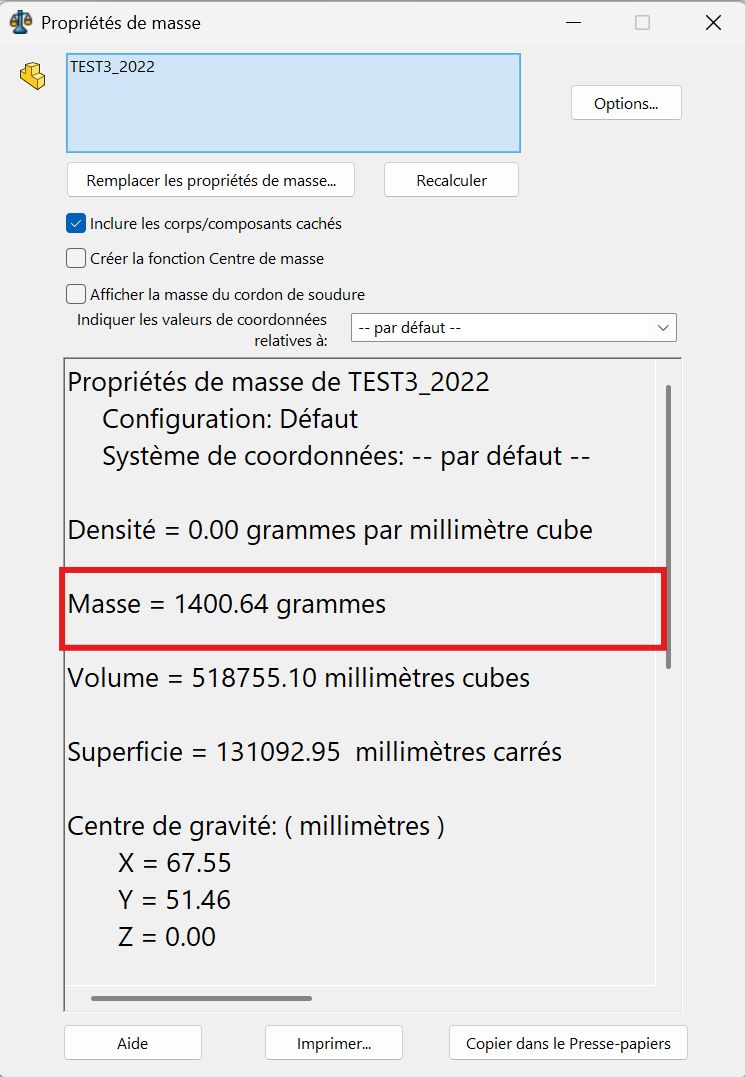

(a) A = 193 mm; B = 88 mm; W = B/2 mm; X = A/4 mm; Y = B+5.5 mm; Z = B+15mm;

The part mass is : 1400.64 gramms

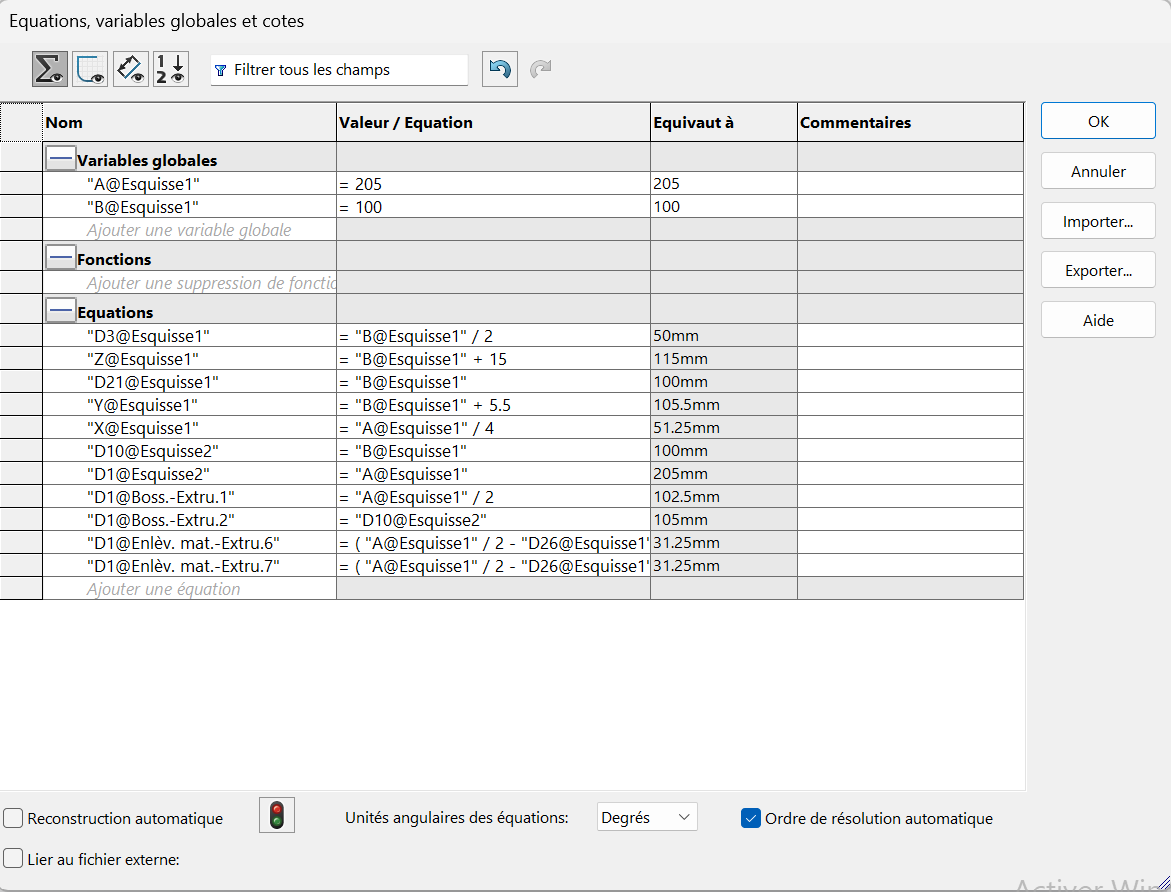

(b) A = 205 mm; B = 100mm; W = B/2 mm; X = A/4 mm; Y =B+5.5 mm; Z = B+15 mm;

The part mass is : 1651.39 gramms

(c) A = 210 mm; B = 105 mm; W = B/2 mm; X = A/4 mm; Y = B+5.5 mm; Z = B+15mm;

The part mass is : 1760.41 gramms

Alternative Perspectives

Multiple paths allow for creating the same part. The part in this test can also be created using the following alternative method:

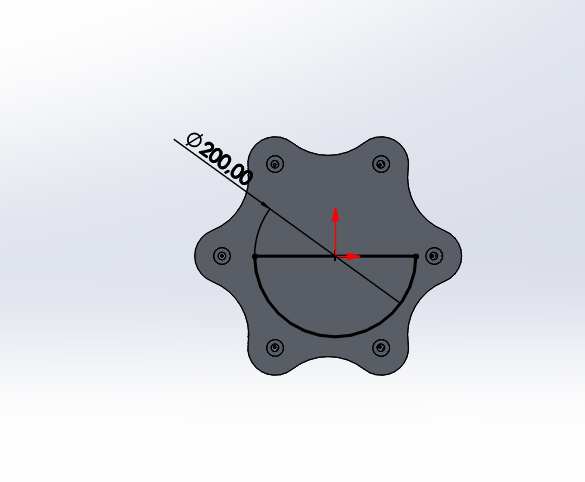

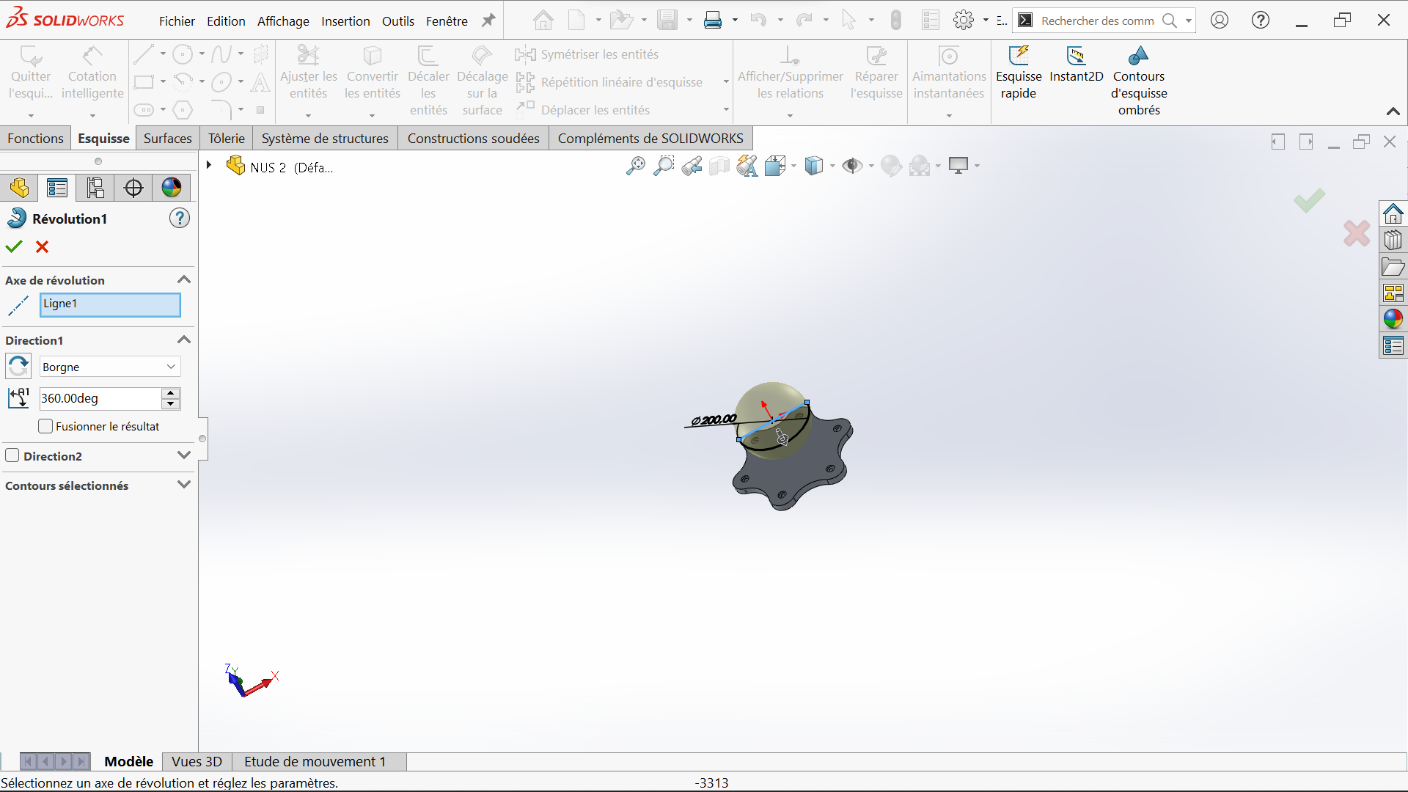

Alternative Method A

On the top plane, create the following sketch and make an extruded boss of "B" mm.

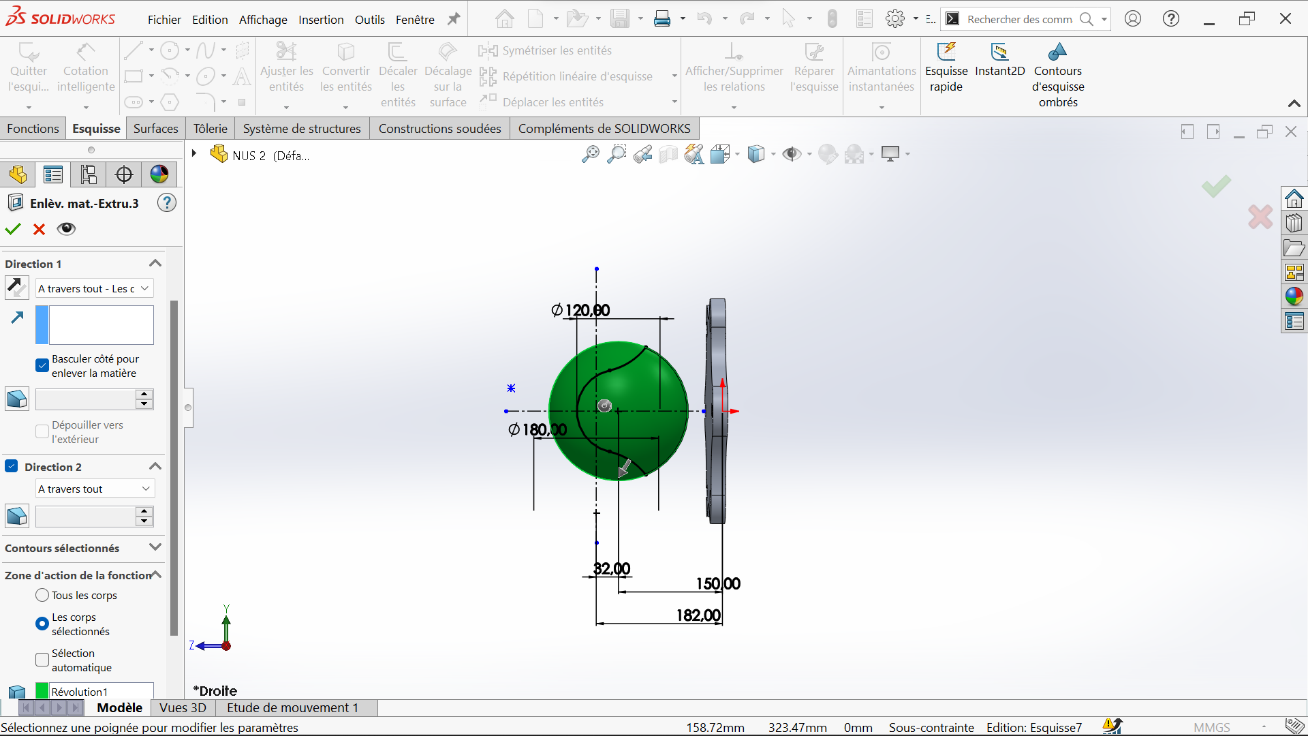

Alternative Method B

On the front plane, make the following sketch and proceed to remove extruded material to obtain the part.

Alternative Method C

Use global variables or dimension directly on the sketches to have the three requested parts with the desired dimension specifications.

Note: This document references multiple technical drawings and sketches that guide the 3D modeling process. The parametric approach using global variables allows for efficient generation of multiple part variants.

Bonus

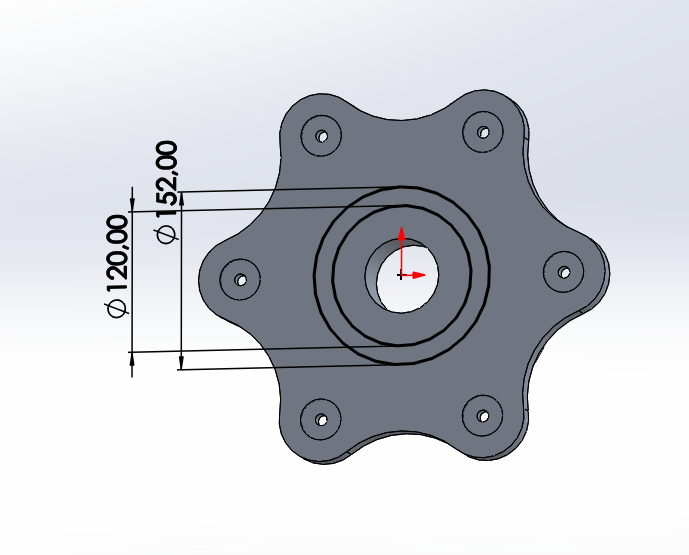

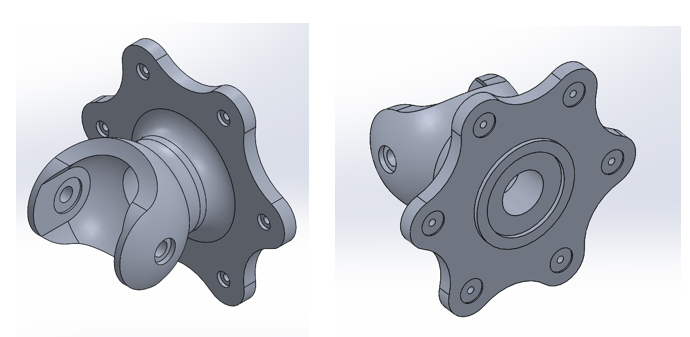

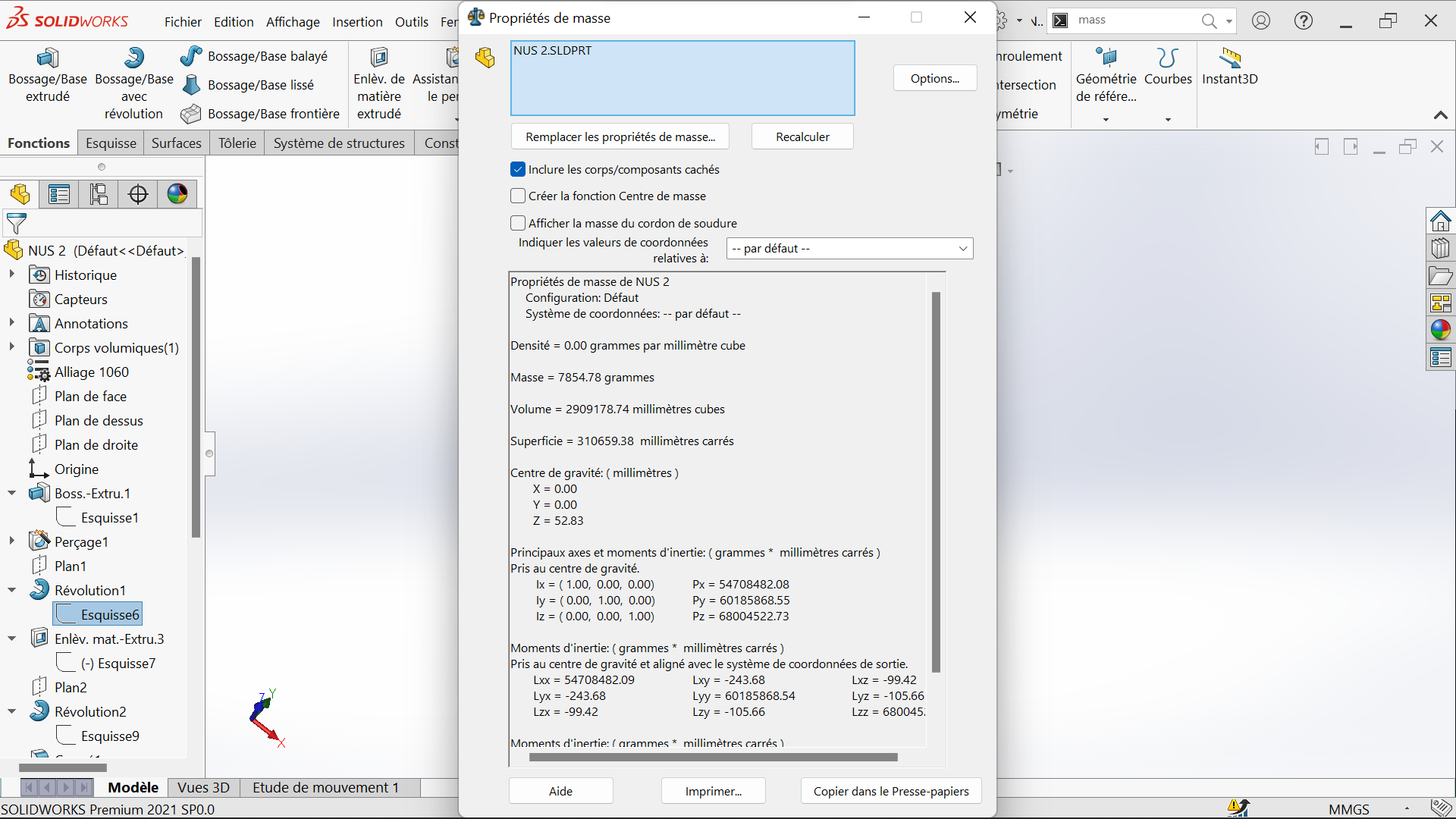

The part mass is 7854,78 gramms

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |