Part I Construction Documentation

Short Demo

Link to Download: Link to download

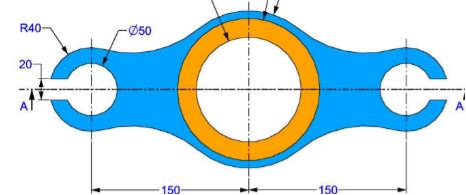

Method Using Successive Circles and Cuts

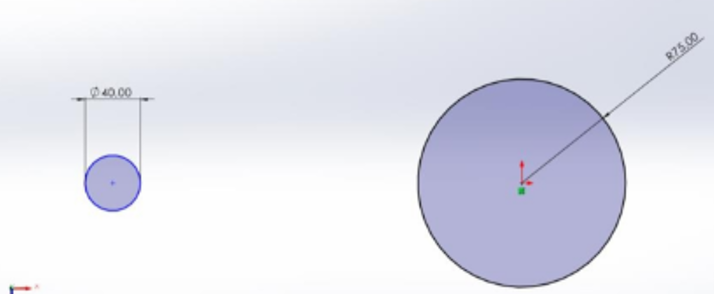

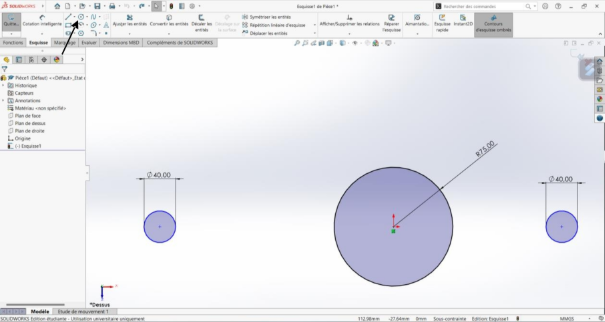

First Step: Creating the Three Base Circles

Description

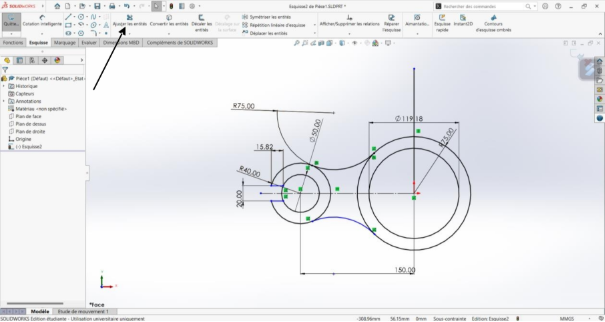

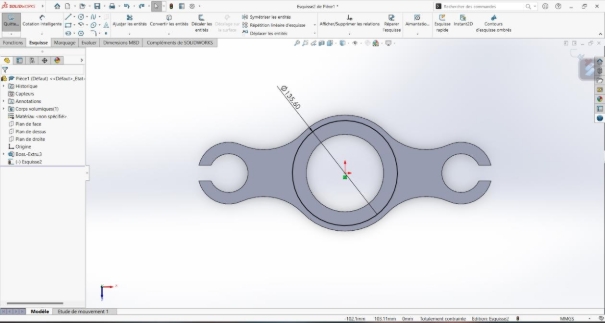

This step involves creating the three main circles to establish the base structure (see following screenshot) of the part: two lateral extensions and a central body.

Actions

Select the XY plane in SolidWorks.

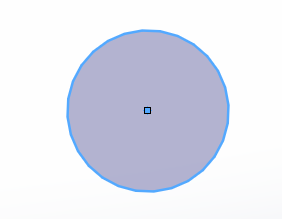

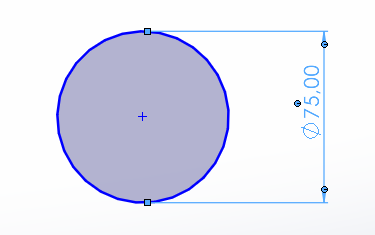

Draw the central circle with radius 75 mm at position (0, 0):

- select circle icon at the top left corner

- design your circle from choosen position

- Use the smart cotation to set a raduis

Draw the left circle:

- Radius: 40 mm

- Position: -150 mm from central circle center on X-axis

Draw the right circle:

- Radius: 40 mm

- Position: +150 mm from central circle center on X-axis

Result

Three circles positioned to form the dumbbell-shaped base geometry.

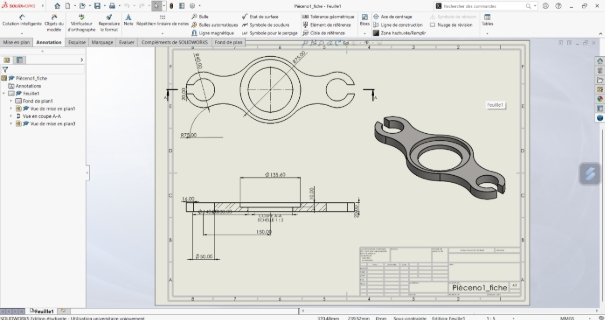

Screenshot 1:

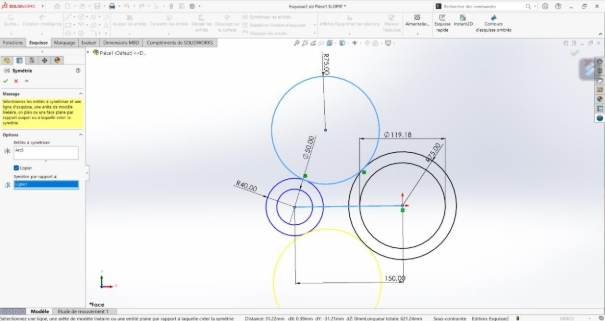

Second Step: Adding Transition Circles

Description

Creation of additional circles to define transition zones and rounded shapes between main elements. The circles allow application of curvature radius in transition areas.

Actions

- Create new transition circles:

- Intermediate circles for smooth connections

- Radius: 75mm

- Strategic positioning for organic curves

- Apply tangent properties to circles

Third Step: Cutting Operations to Form Transitions

Description

Using additional circles to cut and recreate the part's characteristic rounded shapes.

Actions

First series of cuts:

Select circles to use as cutting tools

Select "Fit Entities" tool

Remove excess circle material

Second series of cuts:

- Refine transition shapes

- Create organic curves

- Eliminate unwanted intersections

Result

Dumbbell-shaped organic form with smooth curved transitions between central body and extensions.

Screenshot 3:

Fourth Step: Applying Symmetry Relative to Central Circle's (O,J) Axis

Description

Mirroring the completed portion relative to the central circle's (O,J) axis to facilitate reproduction of transition curves.

Actions

- Select portions to mirror

- Select symmetry axis

- Apply "Mirror Entities" function to selected elements

Result (See Screenshot 4)

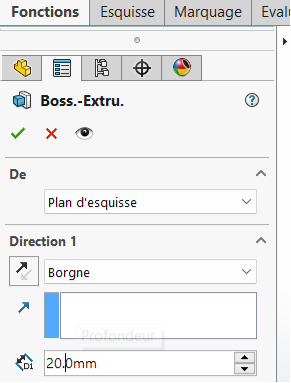

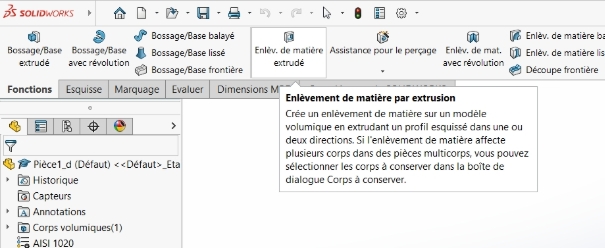

Fifth Step: Base Extrusion

Description

Transforming the obtained 2D part into a 3D component.

Actions

Select the three sketched circles

Use extrusion function

Set extrusion height to 20.00 mm

Extrude perpendicular to XY plane (along Z-axis)

Result

Formation of extruded part.

Screenshot 4

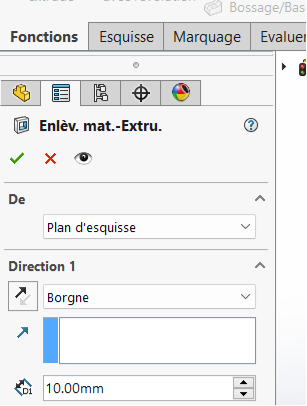

Sixth Step: Creating Main Central Hole

Description

Drilling the large central circular hole that forms the part's main feature, creating the hollowed area at the central circle.

Actions

Select top face of central portion

Draw centered circle:

- Diameter: Ø135.6 mm

- Position: geometric center of central portion

Use through-hole tool

Drill through entire thickness (10 mm)

Measurements

- Depth: 10 mm (through)

Result

Central circular through-hole in main part portion.

Screenshot 5 Location:

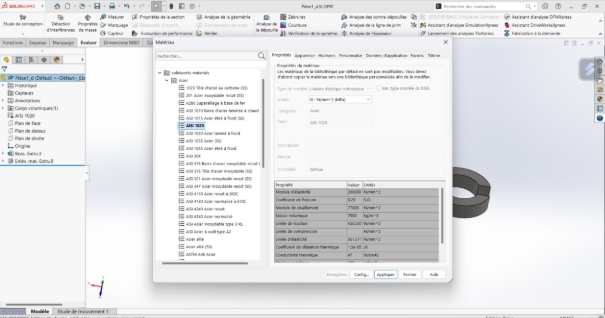

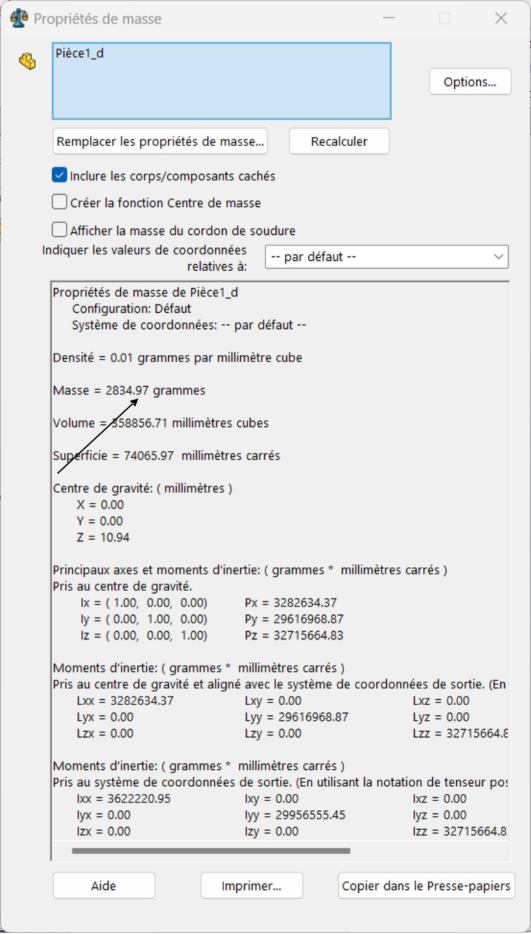

Seventh Step: Finishing and Material Properties

Description

Applying final finishes, verifications, material property definition, and mass determination.

Actions

- Geometric verification:

- Dimension control per technical drawing

- Check for geometric defects

- Create part drawing

- Material application:

- Selection: AISI 1020 Steel

- Density: 0.0079 g/mm³

- Automatic mass calculation

- Final adjustments

Screenshots 6:

Final Measurements

- Material: AISI 1020 Steel (density 0.0079 g/mm³)

Obtained mass: 2834.97 grams